Ground washing machine with adjustable roller brush

A washing machine and rolling brush technology, which is applied in the direction of cleaning carpets, cleaning floors, machine parts, etc., can solve the problems of poor stability and reliability, small lifting adjustment range, easy damage of lifting motor, etc., and achieve reasonable structural design and high lifting adjustment range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

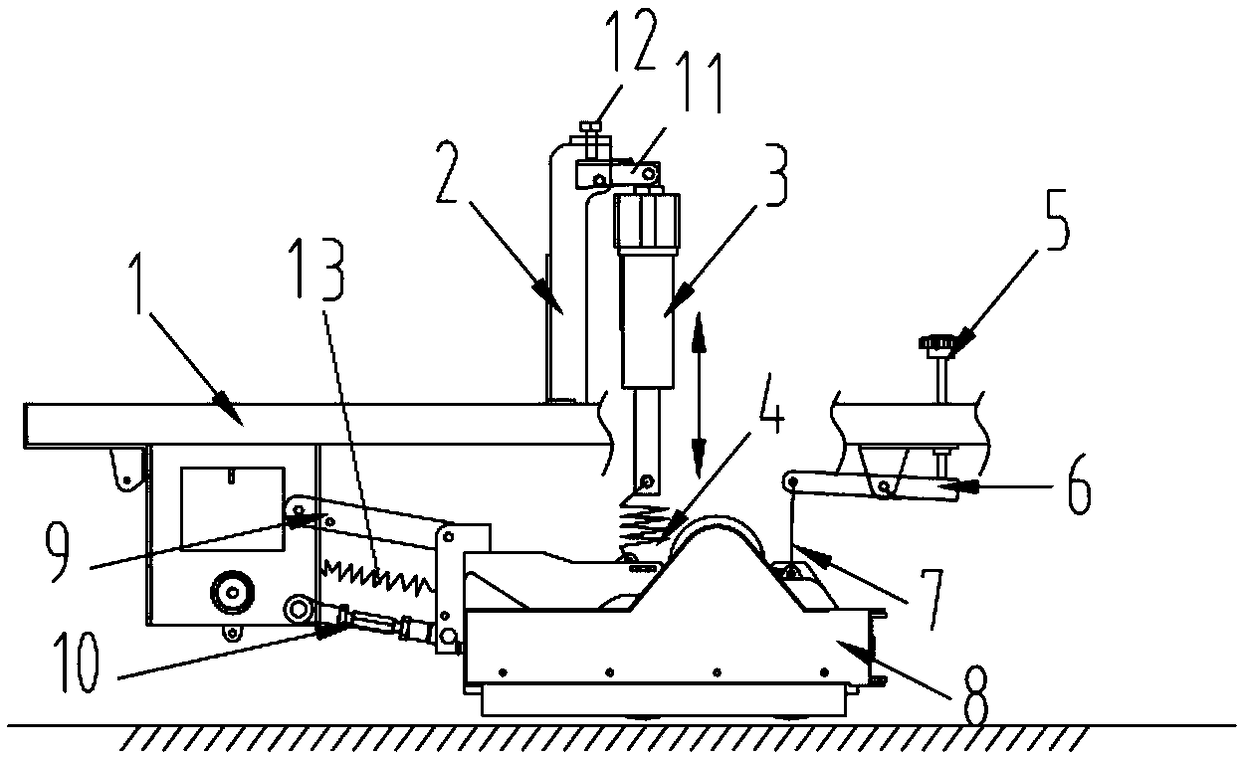

[0017] Such as figure 1 As shown, the scrubber with adjustable roller brushes includes a scrubber chassis 1, a roller brush assembly 8, a lifting motor 3 for driving the roller brush up and down, a shock absorbing spring 4, a lifting connecting rod 9 and a support spring 13 .

[0018] The lifting motor is arranged on the chassis through the fixed bracket 2, and the lower end of the lifting motor is connected with the roller brush assembly through a damping spring 4, and one end of the lifting connecting rod and the supporting spring is connected with the side of the rolling brush assembly, and the lifting connecting rod and the rolling brush assembly are connected together. The other ends of the support springs are all connected with the chassis.

[0019] The upper end of fixed support 2 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com