A kind of palladium-alumina-cordierite composite material and its preparation method and application

A composite material, cordierite technology, applied in the field of palladium-alumina-cordierite composite materials and its preparation, can solve the problem of inability to achieve high dispersion of active components, easy loss of active components, and the interaction between active components and coatings Weakness and other problems, to achieve the effect of prolonging life, simplifying the preparation process, and high degree of palladium dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put the preconditioned cordierite matrix into the reactor, add active agent F127, aluminum isopropoxide, magnesium nitrate hexahydrate, PdCl 2 , HCl, citric acid, ethanol synthesis mother liquor, wherein mass ratio F127: aluminum isopropoxide: magnesium nitrate hexahydrate: PdCl 2: HCl: citric acid: ethanol = 1: 1.1: 0.275: 0.006: 1.8: 0.7: 11 mother liquor 70 ml, seal the reactor and react at 120°C for 2 days, take it out, wash, dry, and calcinate to get this product Invention of said composite material.

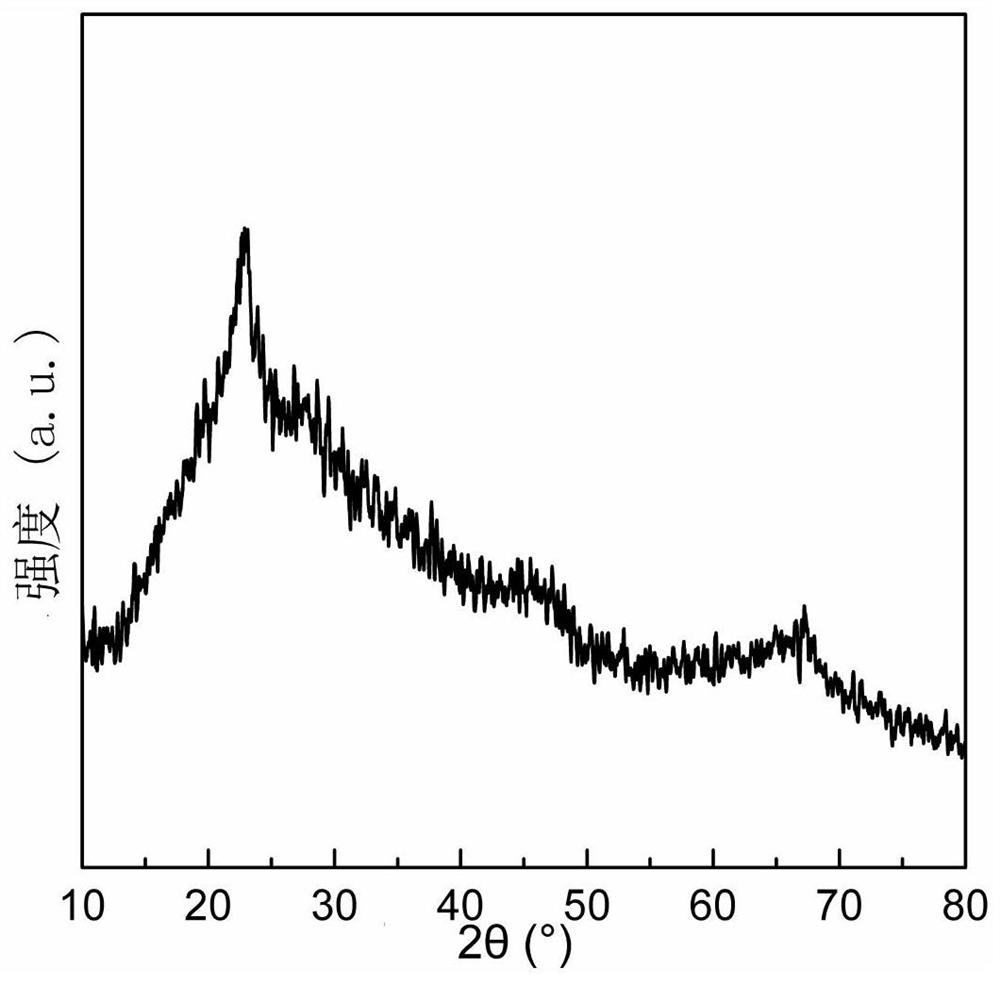

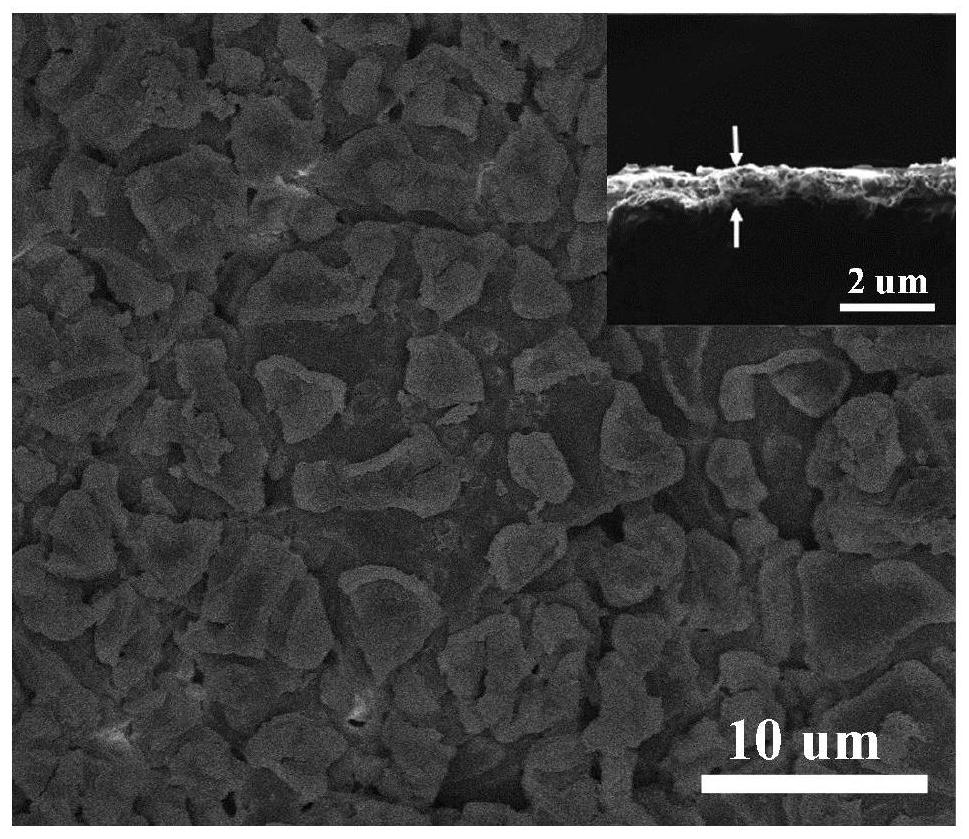

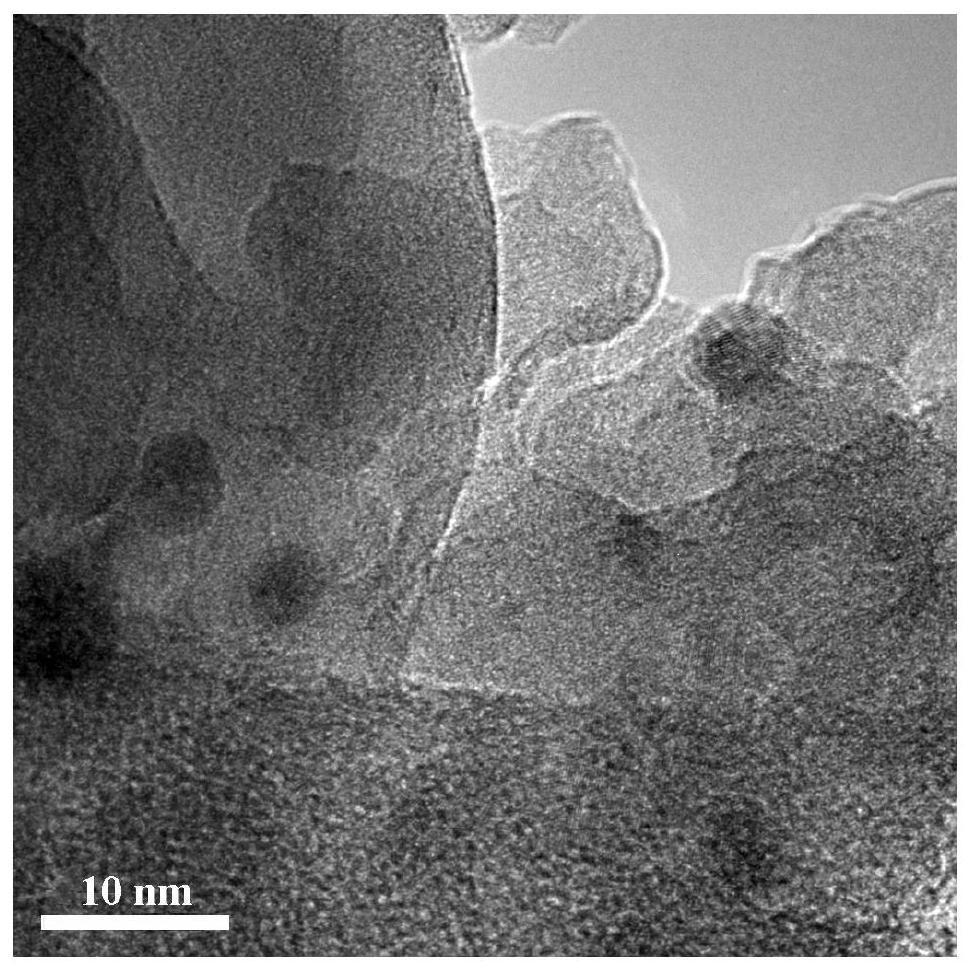

[0039] figure 1 In order to obtain the X-ray diffraction pattern of the composite material (deducting the diffraction peak of the cordierite matrix), it can be determined that the Pd-Al 2 o 3 -cordierite composite material, and in Pd-Al 2 o 3 The active layer contains MgSi x o 2x+1 (x=1, 2, 3) species, whose corresponding diffraction peak is located at 23°, denoted as Pd-Al 2 o 3 -M-1; It is known by weighing: Pd and Al in the composite material 2 o 3 The ...

Embodiment 2

[0044] Using the composite material prepared in Example 1 as a raw material, repeat the steps in Example 1 twice, and the prepared Pd-Al 2 o 3 - The cordierite composite material is denoted as Pd-Al 2 o 3 -M-2. It is equivalent to that the product obtained in Example 2 has undergone a total of 3 reactions starting from the pretreated cordierite.

[0045] Figure 4 In order to obtain the X-ray diffraction pattern of the composite material (deducting the diffraction peak of the cordierite matrix), it can be determined that the Pd-Al 2 o 3 -cordierite composite material, and in Pd-Al 2 o 3 The active layer contains MgSi x o 2x+1 (x=1, 2, 3) Species. After weighing, it is known that Pd and Al are contained in the composite material 2 o 3 The total mass percentage is 2.58%, wherein the mass percentage of Pd metal is 0.50%, the mass percentage of cordierite matrix is 97.42%, MgSi x o 2x+1 The mass ratio of (x=1, 2, 3) species relative to the porous alumina was 5.0%. ...

Embodiment 3

[0050] Put the preconditioned cordierite matrix into the reactor, add surfactant F127, aluminum isopropoxide, magnesium nitrate hexahydrate, PdCl 2 , HCl, citric acid, ethanol synthesis mother liquor, the mass ratio is F127: aluminum isopropoxide: magnesium nitrate hexahydrate: PdCl 2 : HCl: citric acid: ethanol = 1: 1.1: 0.275: 0.006: 1.8: 0.7: 11 synthetic solution 70 ml, seal the reactor and place it in an oven at 120°C for 4 days, take it out, wash, dry and calcinate , the resulting composite material is denoted as Pd-Al 2 o 3 -M-3.

[0051] Figure 7 In order to obtain the X-ray diffraction pattern of the composite material (deducting the diffraction peak of the cordierite matrix), it can be determined that the Pd-Al 2 o 3 -cordierite composite material, and in Pd-Al 2 o 3 The active layer contains MgSi x o 2x+1 (x=1, 2, 3) Species. Known by weighing: Pd and Al in the composite material 2 o 3 The total mass percentage is 0.99%, of which Pd metal accounts for P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap