Automobile bumper full-aspect paint spraying workbench

A technology for automobile bumpers and workbenches, which is applied in the direction of spraying devices, etc., can solve the problems that automobile bumpers cannot be sprayed in batches and all aspects, and achieve the effects of good painting effect, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

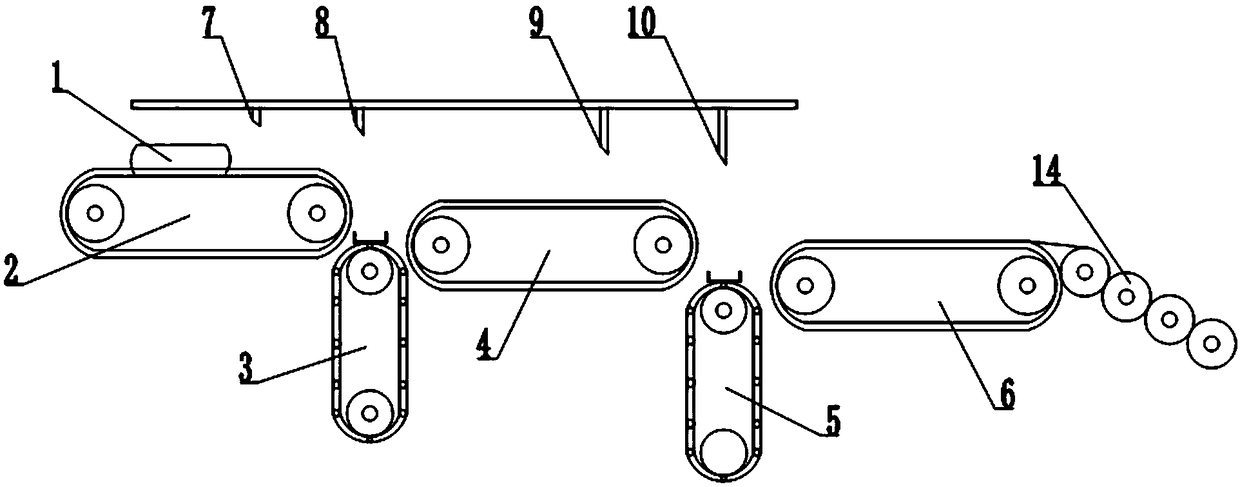

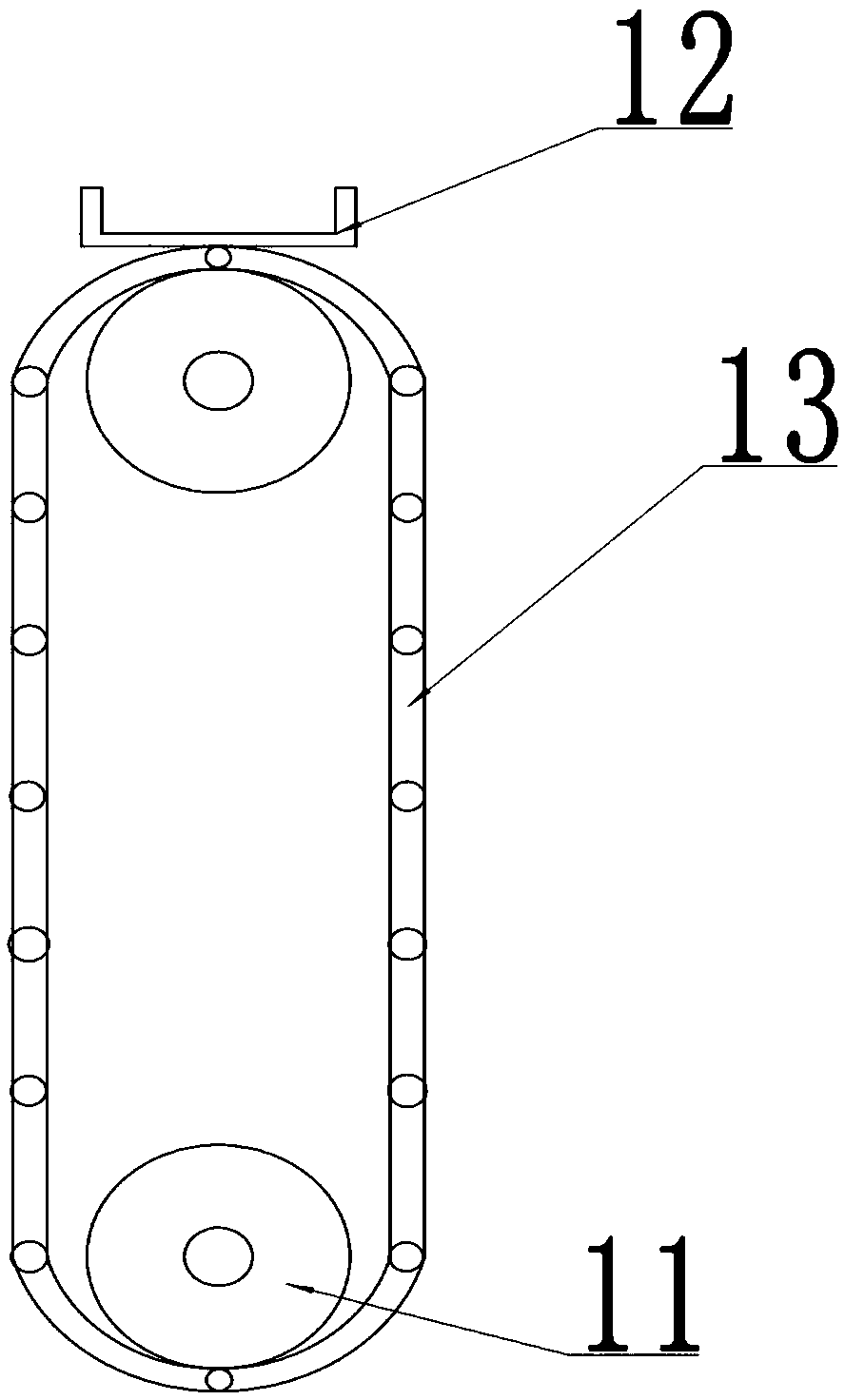

[0015] Reference numerals in the accompanying drawings include: automobile bumper 1, the first conveyor belt 2, the first conveyor chain 3, the second conveyor belt 4, the second conveyor chain 5, the third conveyor belt 6, the first spray gun 7, the second spray gun 8. The third spray gun 9, the fourth spray gun 10, the roller 11, the U-shaped groove 12, the chain 13, and the conveying roller 14.

[0016] The embodiment is basically as attached figure 1 , figure 2 Shown: a car bumper all-round painting workbench according to the present invention, including a workbench, which is provided with a transmission mechanism that moves clockwise. The transmission mechanism includes a first conveyor belt 2, a first conveyor chain 3, a Two conveyor belts 4, the second conveyor chain 5 and the third conveyor belt 6, the first conveyor belt 2, the second conveyor belt 4 and the third conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com