Modular design closed cooling water tank device and quick changing method

A modular design, cooling water tank technology, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of no interchangeability, high cost of spare parts storage, long replacement time of water tanks, etc., to reduce spare parts The storage and positioning are simple and reliable, and the effect of convenient equipment selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

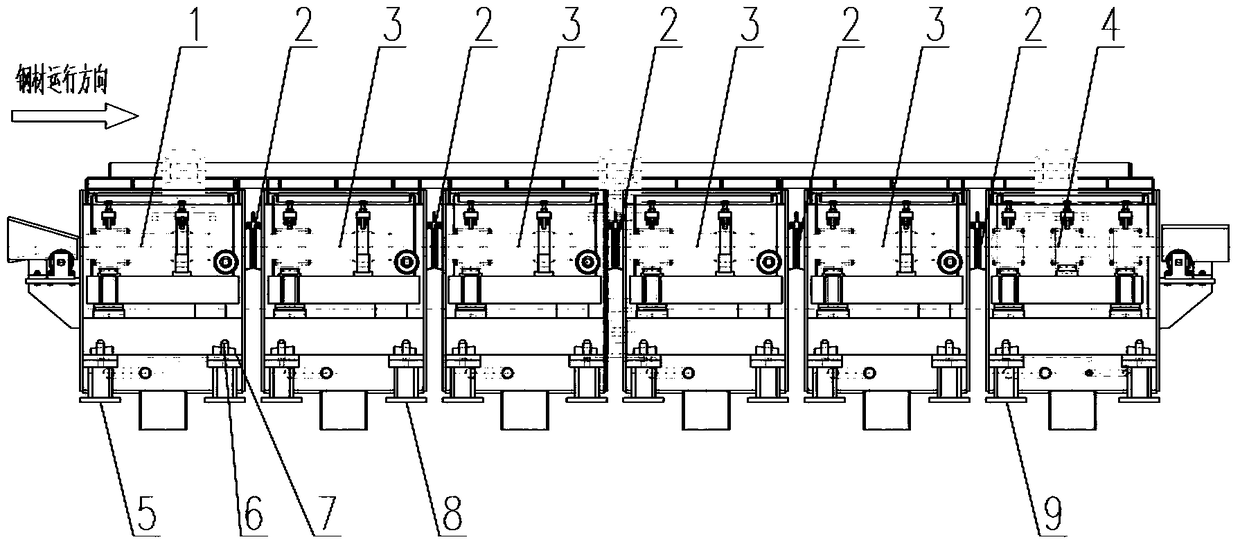

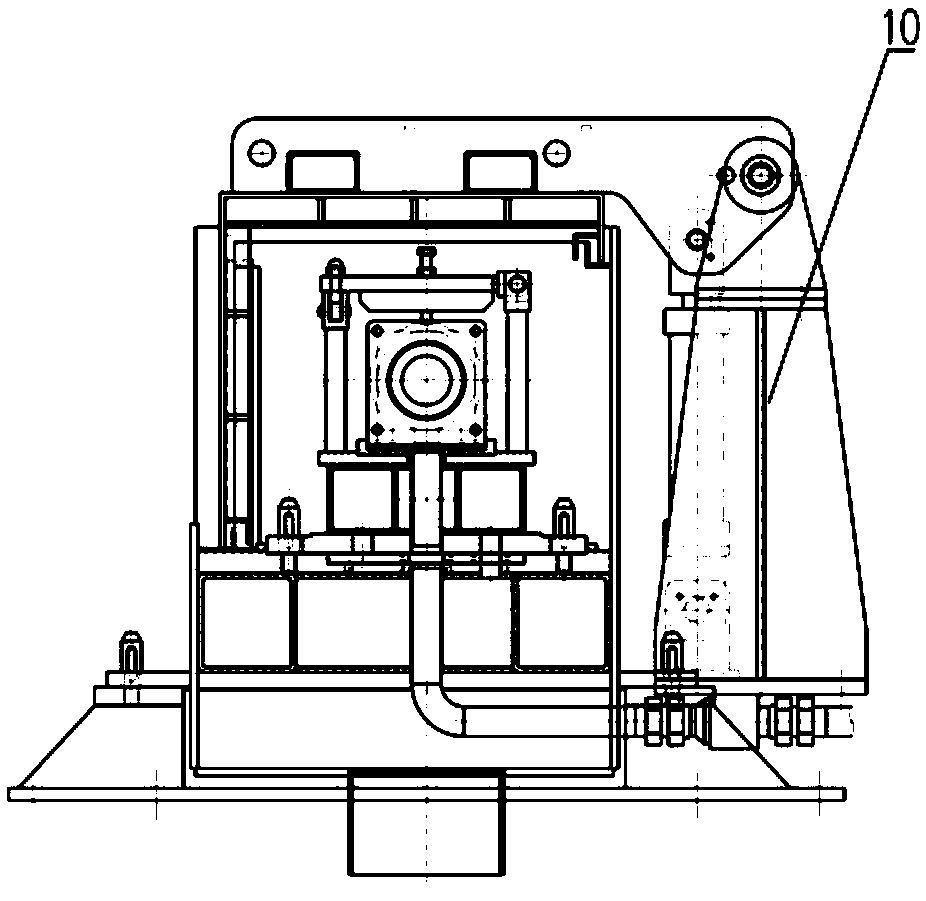

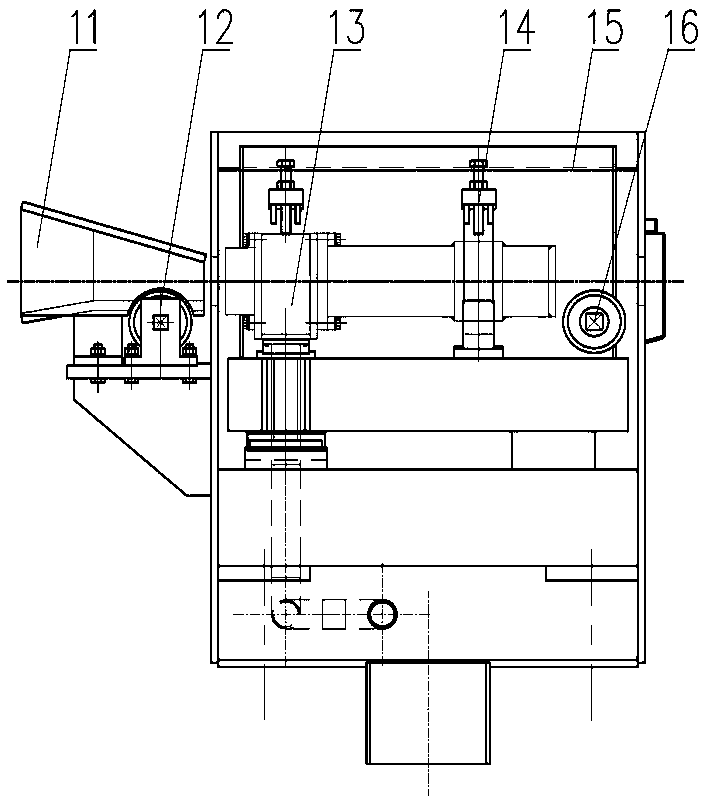

[0038] like Figure 1-10 As shown, the reference signs are as follows: inlet water tank 1, transition waterproof ring 2, intermediate water tank 3, outlet water tank 4, inlet water tank base 5, fixed pin 6, fixed wedge 7, intermediate water tank base 8, outlet water tank base 9, seal Waterproof cover 10, entrance guide groove 11, entrance guide roller 12, cooling device 13, pressing device 14, box body 15, supporting roller 16, quick change joint 17, cooling device 2 18, pressing device 2 19. Box two 20, idler two 21, quick change joint two 22, water seal device 23, compression device three 24, air seal device one 25, box three 26, air seal device two 27, exit guide roller 28 , Outlet guide groove 29, quick-change joint 30, three connecting seats 31, bracket 32, oil cylinder connecting seat 33, oil cylinder support 34, oil cylinder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com