Metal sheet flanging equipment

A metal sheet and flanging technology, which is applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of high production cost and low production efficiency, and achieve low cost, high production cost, and metal flanging. Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

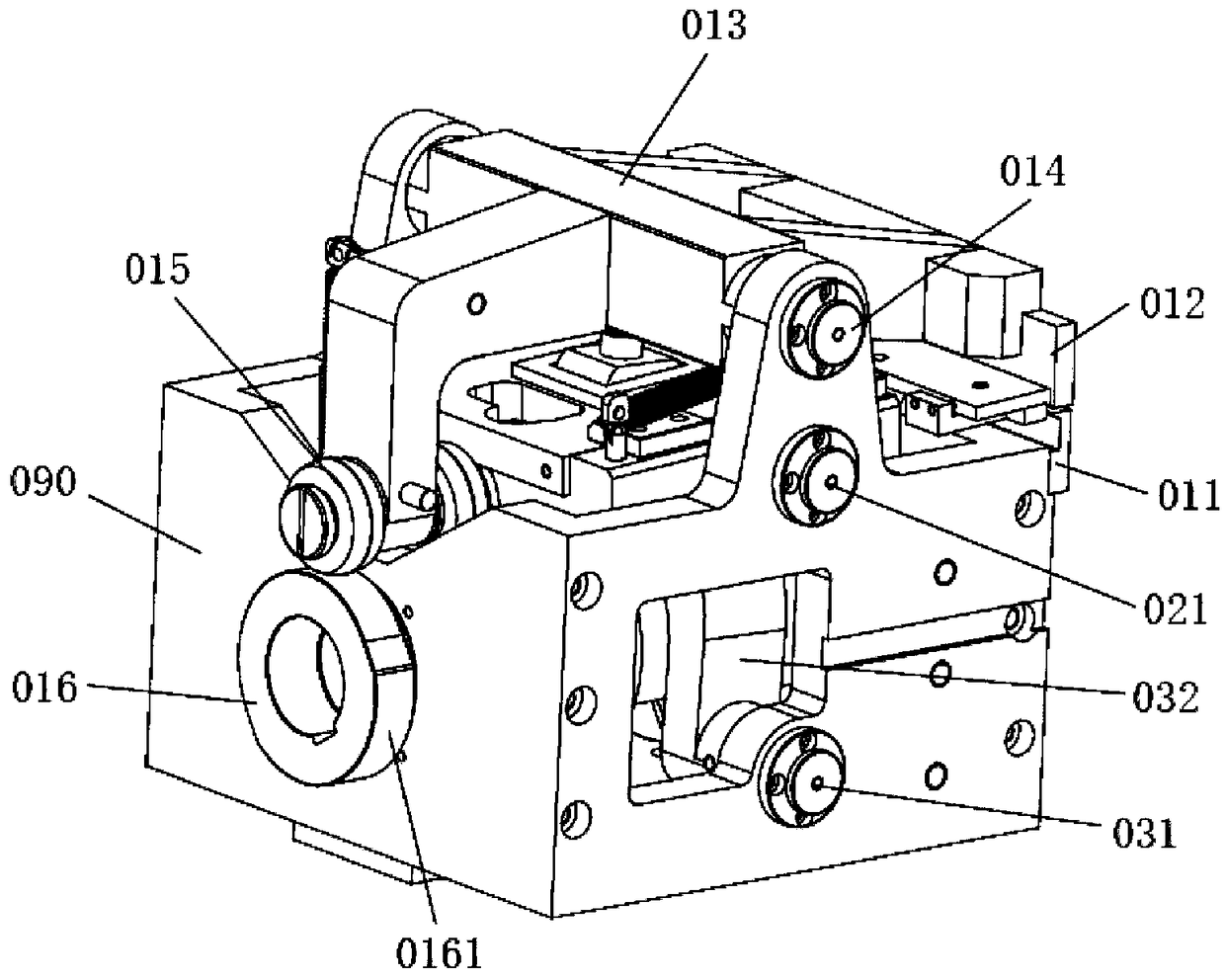

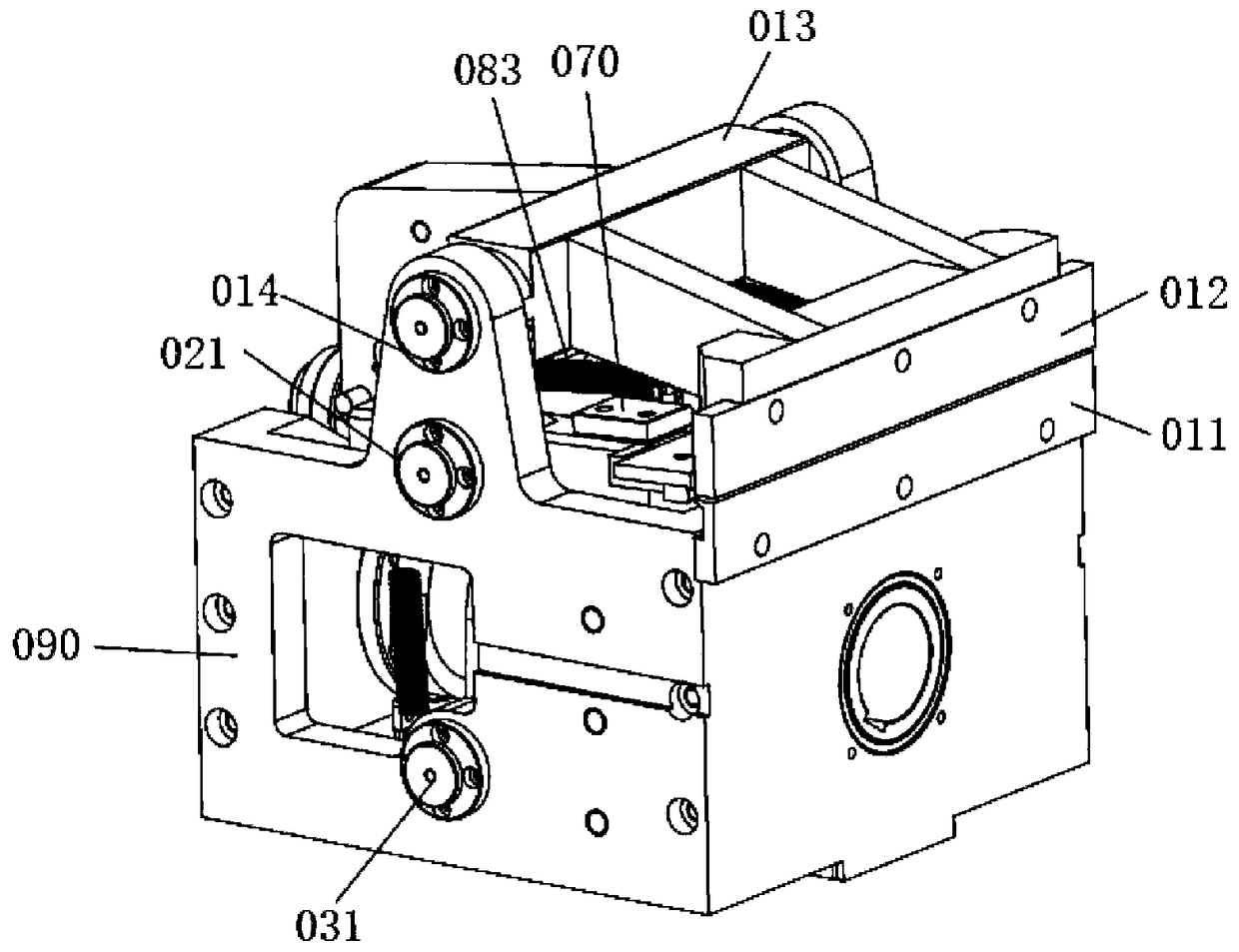

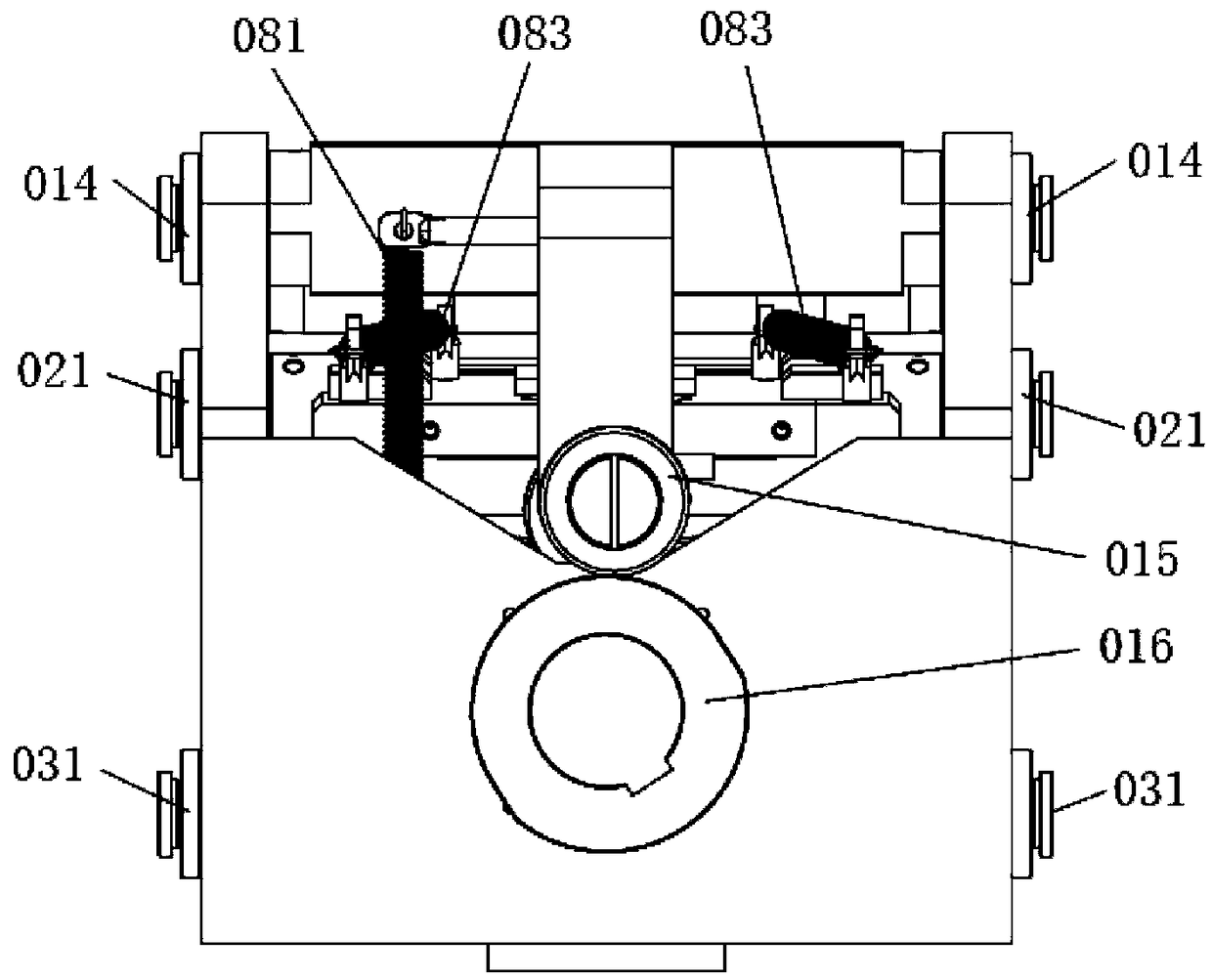

[0048] Such as Figure 1-3 As shown, this embodiment discloses a metal sheet flanging device, which can flang the metal sheet to its lower surface, such as figure 1 shown. The metal sheet flanging device includes a housing 090, a clamping mechanism for clamping the metal sheet, and a flanging mechanism capable of flanging the metal sheet. The flanging mechanism includes a pressing block 050 for flanging the metal sheet, and the pressing block 050 needs to tilt and move to the downward pressing plate 011, and pushes the part of the metal sheet to be flanged to be bent to complete the flanging.

[0049] Specifically, the clamping mechanism includes an upper pressing plate 012, a lower pressing plate 011 and a first lever mechanism, the lower pressing plate 011 is fixed on the casing 090, the upper pressing plate 012 is fixed on one end of the movable plate A013 of the first lever mechanism, and the fulcrum of the first lever mechanism A014 is arranged on the shell 090, and the...

Embodiment 2

[0061] Such as Figure 11-14 As shown, the metal sheet flanging equipment of the second embodiment is basically the same as the first embodiment above, and this embodiment only describes the differences between the two, and the same structure will not be repeated here.

[0062] In this embodiment, the metal sheet flanging equipment can flang the metal sheet to its upper surface. Correspondingly, the pressure block 050 in the flanging mechanism needs to be tilted and moved to the upper pressing plate 012 .

[0063] For this reason, the upper platen 012 in the clamping mechanism is provided with a slope for flanging the metal sheet; see Figure 13 The movable plate B022 in the flanging mechanism is provided with a roller B023 near one end of the briquetting block 050, the roller B023 contacts the cam B024, and when the flange B0241 of the cam B024 contacts the roller B023, the briquetting block 050 moves up. Afterwards, under the action of the flanging mechanism and the moving ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap