Spatial circular arc swing welding interpolation method for arc welding robot

A space arc and robot technology, applied in arc welding equipment, welding equipment, complex mathematical operations, etc., can solve problems such as local stress concentration, process performance defects, welding is not strong enough, etc., and achieve the effect of uniform contact between solder and weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

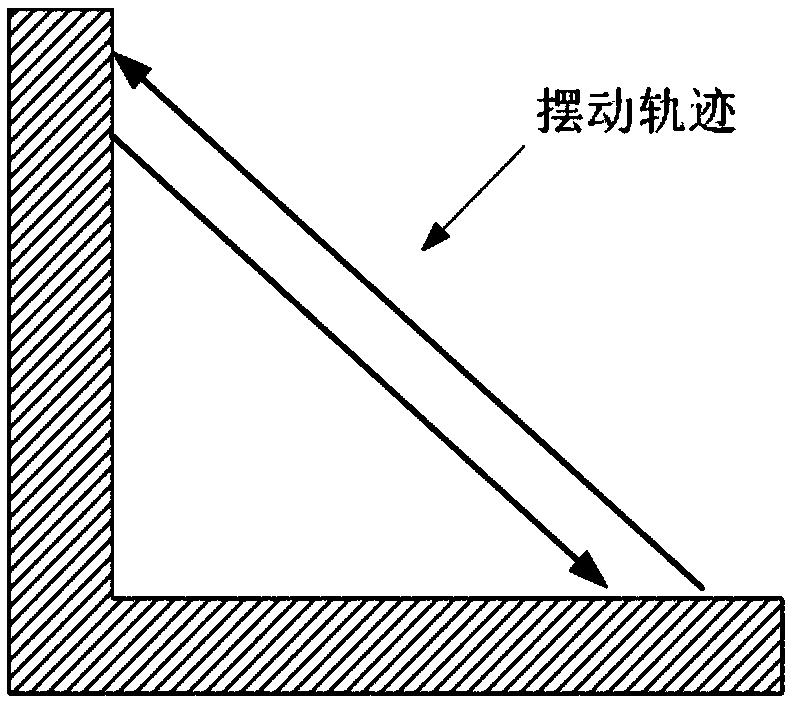

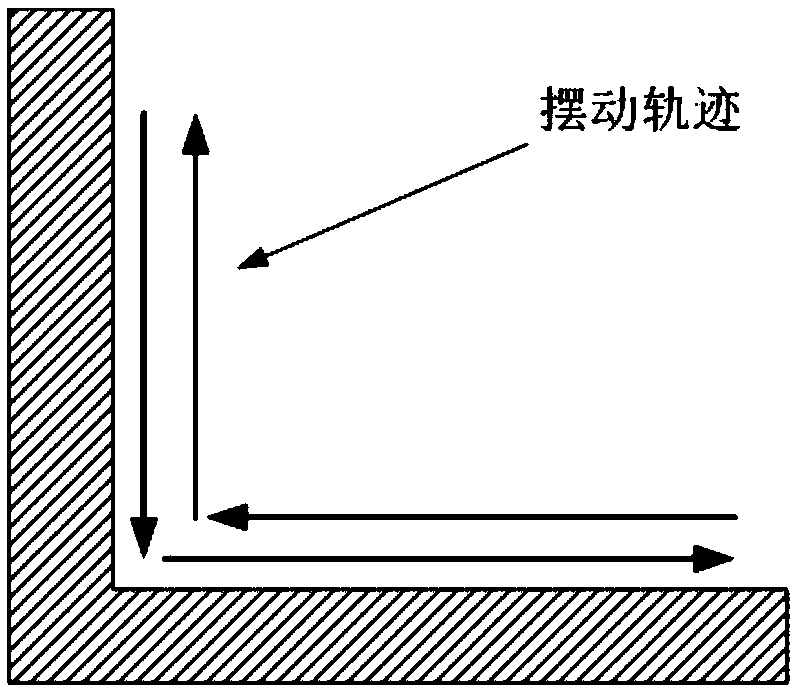

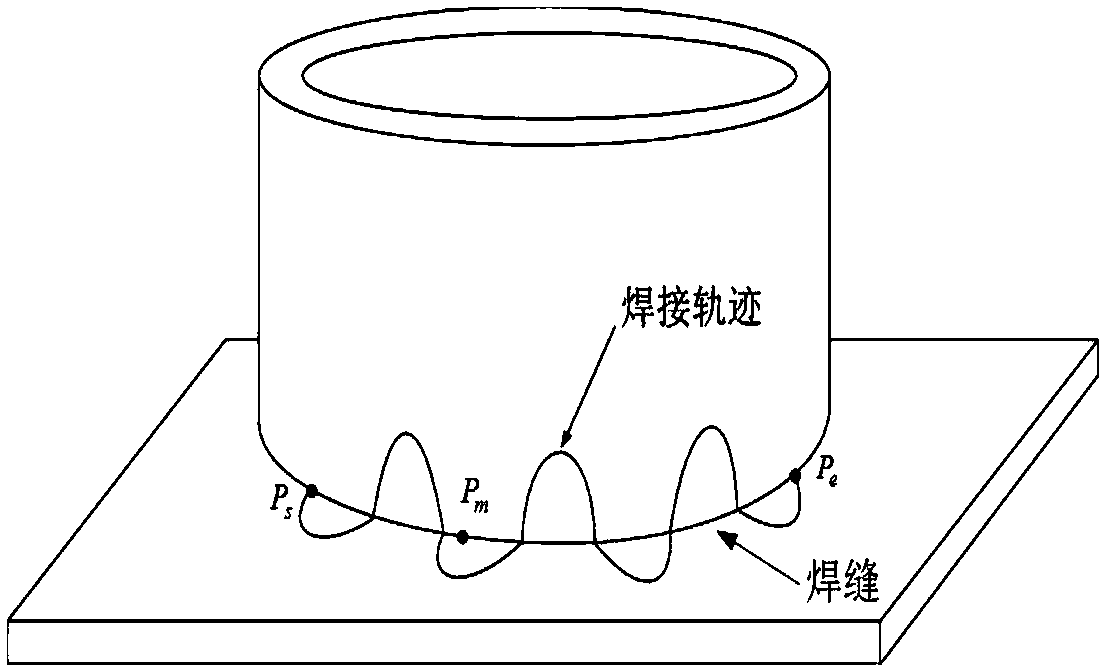

[0048] Such as Figure 1-6As shown, the following parameters are determined: the starting point of sinusoidal line interpolation P s =(x s ,y s ,z s ), end point P e =(x e ,y e ,z e ), the far point of the robot coordinate system is (0, 0, 0), The start and end points determine the straight line for weaving welding. The formula of the sinusoidal curve is y=Asin(Bx), where A represents the amplitude, and B determines the period of the sinusoidal curve;

[0049] Calculates the arc length of a sine curve. The arc differential formula of a sine curve is Using numerical inte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap