A device and method for magnetic field-assisted finishing of complex curved surfaces based on parallel mechanism

A complex curved surface, magnetic field-assisted technology, applied in the direction of grinding frame, grinding slide plate, grinding workpiece support, etc., can solve the problems of unclear removal mechanism, the need to improve the magnetic grinding experimental device, instability, etc., to improve the optical efficiency. Finishing efficiency, achieving full contact, satisfying the effect of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

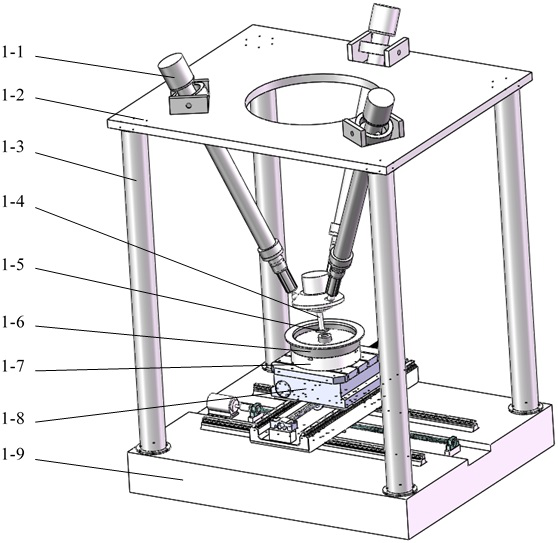

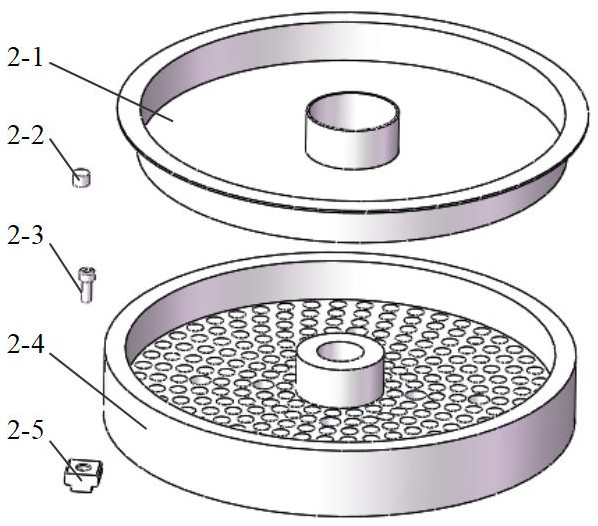

[0016] Specific implementation mode one: combine figure 1 and figure 2 The device described in this embodiment includes a three-bar parallel mechanism 1-1, a connecting plate 1-2, a column 1-3, a workpiece clamping device 1-4, a magnetic field generating device 1-6, a rotating platform 1-7, and a three-axis A precision displacement platform 1-8 and a base 1-9, the magnetic field generating device 1-6 includes a baffle 2-1, a magnetic pole 2-2, a T-bolt 2-3, a circular groove plate 2-4 and a T-nut 2 -5, the three-bar parallel mechanism 1-1 is installed on the connecting plate 1-2, one end of the column 1-3 is connected to the connecting plate 1-2, the other end is connected to the base 1-9, and one end of the rotating platform 1-7 It is fixed on the three-axis precision displacement platform 1-8, and the other end is fixedly connected to the magnetic field generator 1-6, and the parts to be processed 1-5 are fixedly connected to the three-bar parallel mechanism 1-1 through th...

specific Embodiment approach 2

[0017] Specific implementation plan two: combine figure 1 Describe a complex curved surface magnetic field assisted finishing device based on a parallel mechanism described in this embodiment, characterized in that: the three-bar parallel mechanism 1-1 has six degrees of freedom, and can realize high-speed rotation of the parts 1-5 to be processed and multi-degree-of-freedom control. The three-bar parallel mechanism 1-1 can be a 6-sps robot, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 Explain that the magnetic field generating device 1-6 in this embodiment can realize forward rotation and reverse rotation during finishing processing, and cooperate with the rotary motion of the three-bar parallel mechanism 1-1 to increase the size of the parts to be processed 1-5 and the magnetic field generating device The relative movement of 1-6 improves the finishing processing efficiency, and the others are the same as the specific embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com