Series connection nine-degree-of-freedom spraying robot

A technology of spraying robot and degree of freedom, which is applied in the direction of manipulators, spraying devices, program control manipulators, etc., can solve problems such as environmental pollution, unfavorable health of operators, limited working space characteristics, development costs, etc., to achieve large flexible working space, Easy joint control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

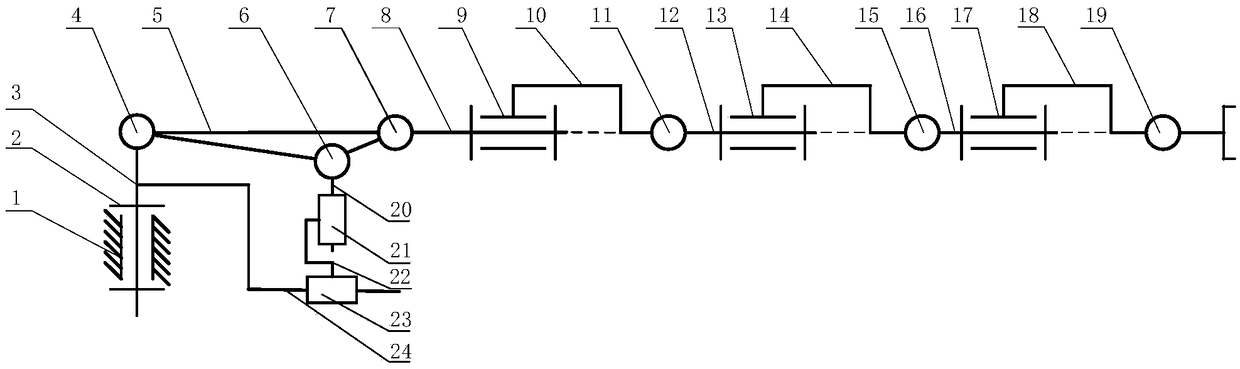

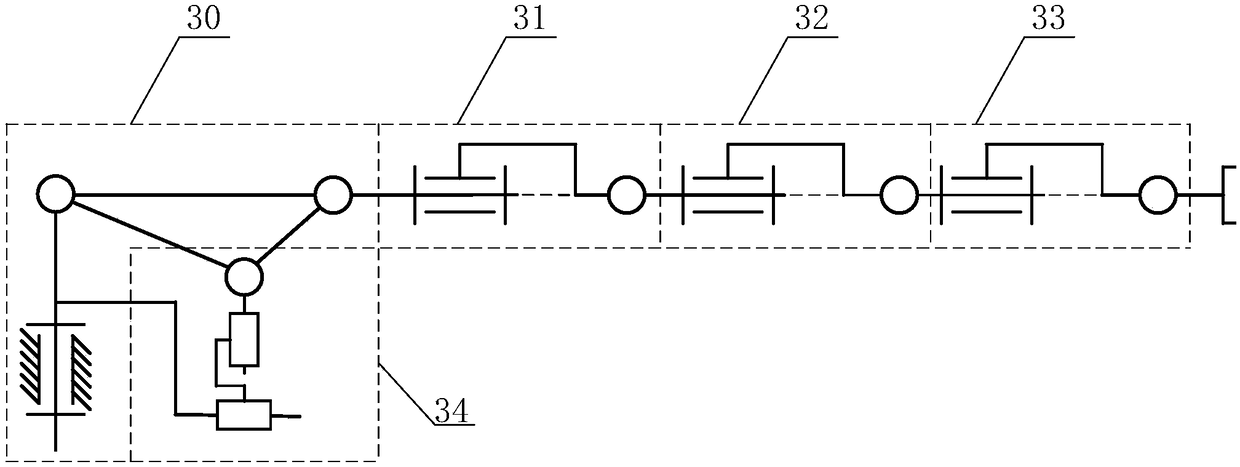

[0027] See attached figure 1 And attached image 3 : A tandem nine-degree-of-freedom spraying robot, comprising: a work positioning mechanism 30, a first articulated chain assembly 31, a second articulated chain assembly 32, a third articulated chain assembly 33 and an auxiliary support mechanism 34;

[0028] The working positioning mechanism 30 is composed of a base platform 1, a first rotary joint 2, a first connecting rod 3, a first pitching joint 4, a second connecting rod 5 and a third pitching joint 7, and the base platform 1 and The first connecting rod 3 is connected by a rotary pair to form the first rotary joint 2, and the first connecting rod 3 and the second connecting rod 5 are connected by a rotating pair to form the first pitch joint 4, and the second connecting rod 5 and the first A articulated chain assembly 31 is connected through a rotary pair to form the third pitch joint 7, and the working positioning mechanism 30, the first articulated chain assembly 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com