Production system for veneer

A production system and veneer technology, applied in special forming/shaping machines, wood processing appliances, manufacturing tools, etc., can solve the problems of cumbersome process, low veneer production efficiency, unable to meet cutting requirements, etc., and achieve simple operation process. , High production efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

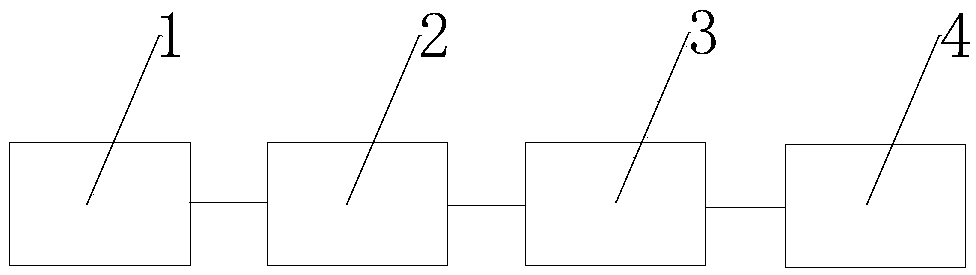

[0025] refer to Figure 1 to Figure 3 , this embodiment discloses a veneer production system, comprising a rotary cutting device 1 , a veneer drying device 2 , a veneer defect cutting device 3 , and a veneer sewing device 4 connected in sequence.

[0026] The outlet of the rotary cutting device 1 and the inlet of the veneer drying device 2 are connected by a conveyor belt, and the outlet of the veneer drying device 2 is conveyed to the veneer defect removal device 3 via the conveyor belt to perform defect removal work, Cover the defect with the same type of veneer of appropriate size according to the size of the defect, transport it to the veneer suture device 4 by conveyor belt, lay the suture line, and complete the repair of the defect by gluing and gluing.

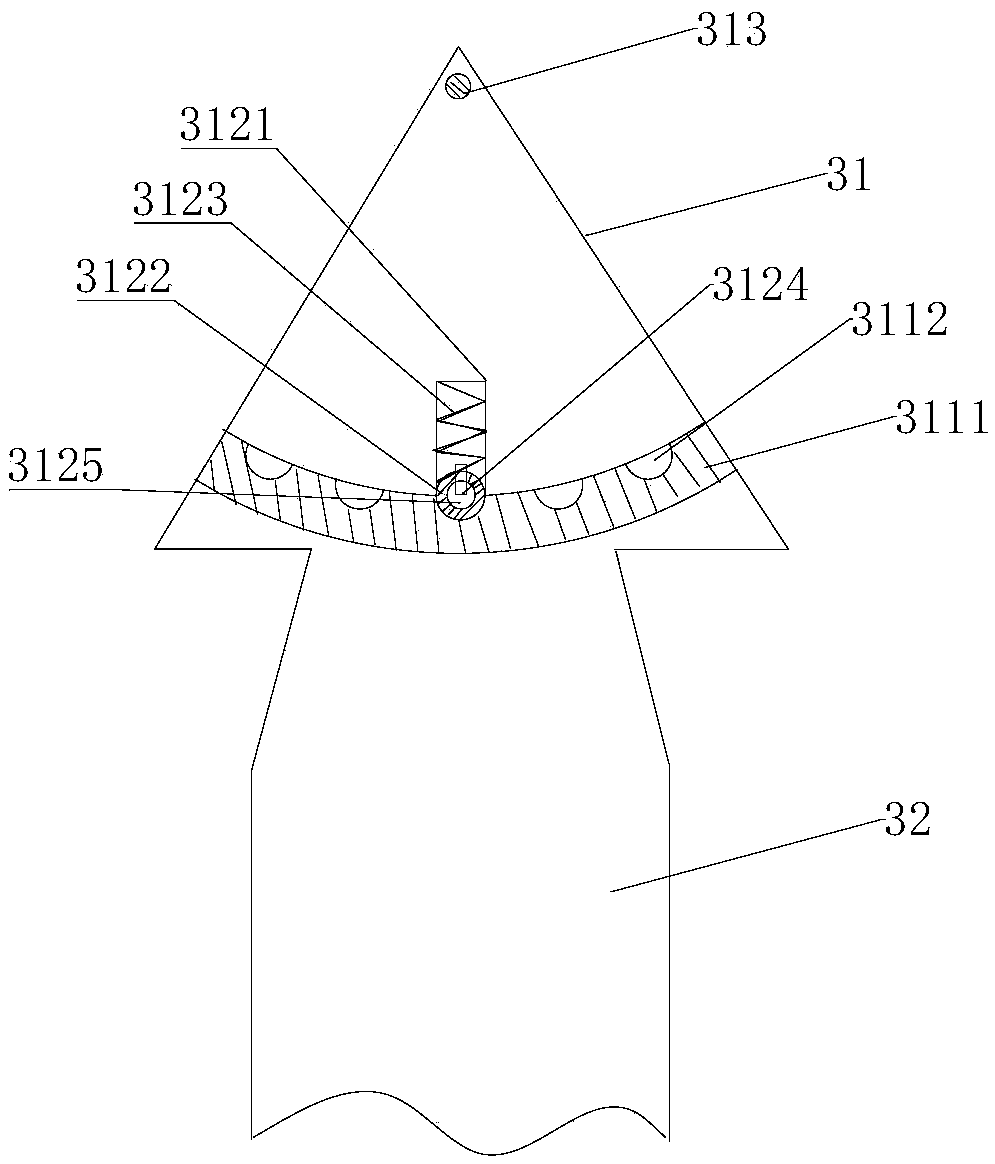

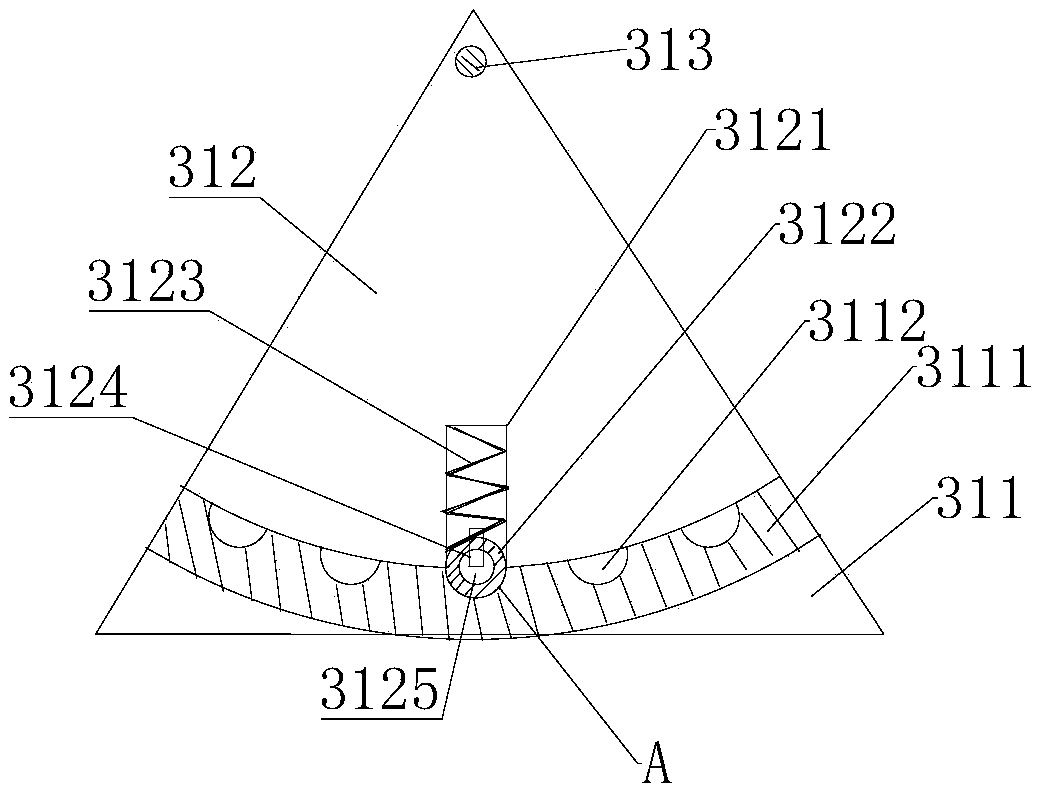

[0027] The removal device 3 of the veneer defect includes a multi-purpose cutter head body 31 and a blade body 32 connected to the cutter head. The multi-purpose cutter head body 31 includes a triangular part 311 and a ...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment is that the bottom edge of the triangular part 311 is connected to the blade body 32 through integral molding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

| Vertical distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com