Automatic Mylar stripping device

A technology of automatic peeling and peeling mechanism, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of damaged Mylar quality, heavy tasks, low peeling efficiency, etc., and achieve the goal of improving peeling quality and reducing work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

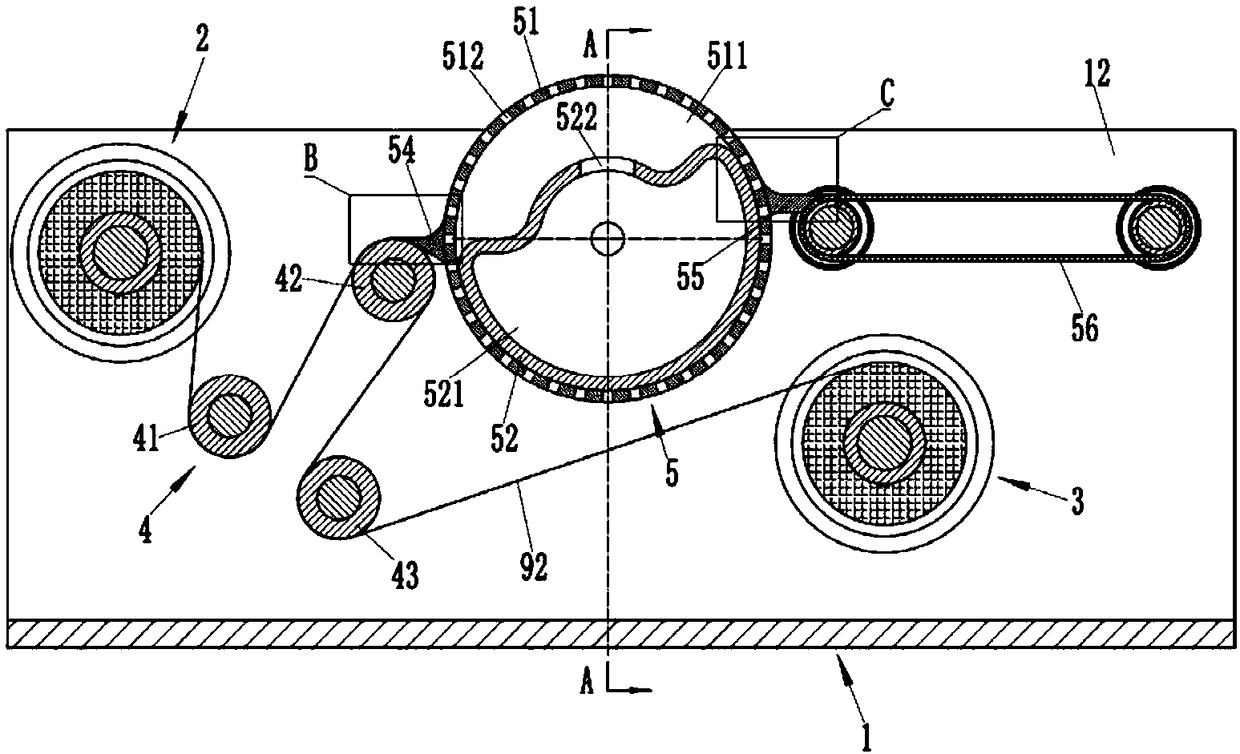

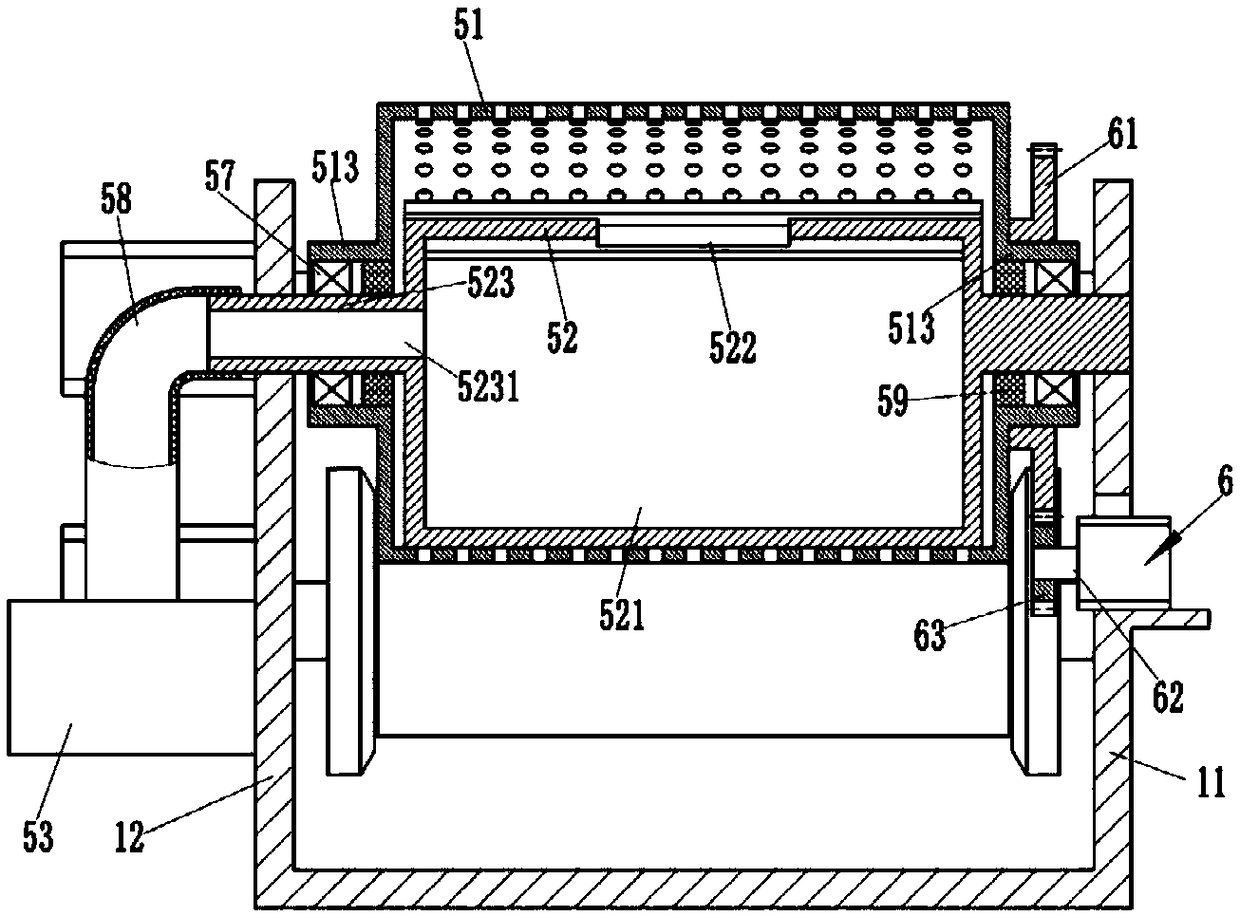

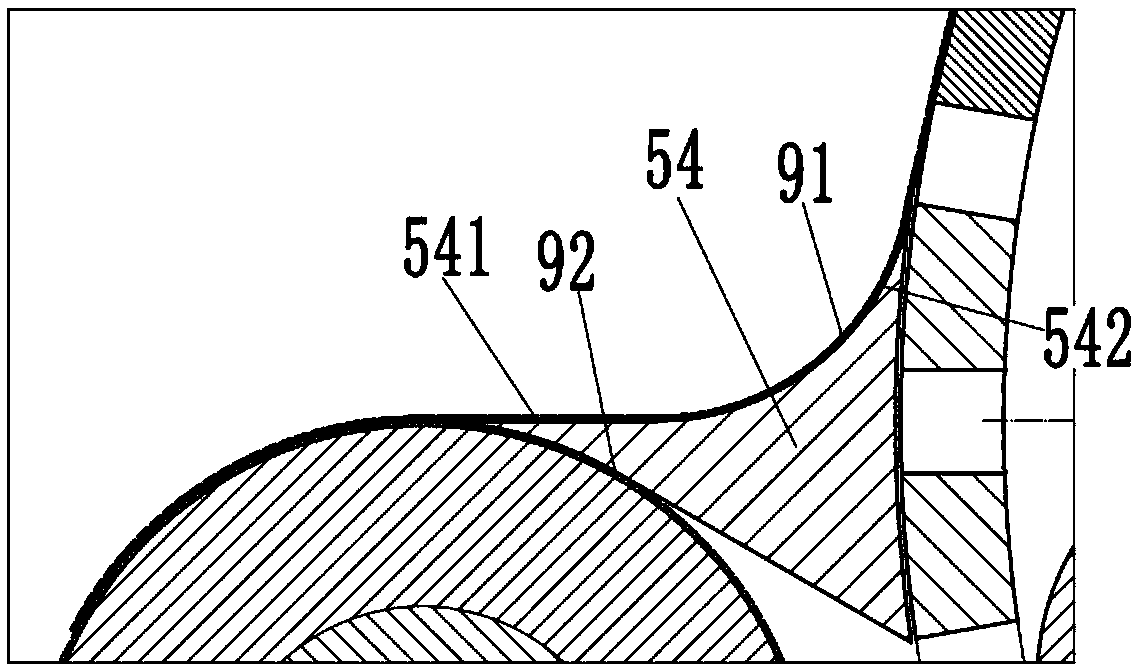

[0015] Examples, see e.g. Figure 1 to Figure 4 As shown, a Mylar automatic stripping device comprises a U-shaped frame 1, the left end of the U-shaped frame 1 is provided with an unwinding mechanism 2, and the right end of the U-shaped frame 1 is provided with a winding mechanism 3, and the unwinding mechanism 2 and the winding mechanism 3 are provided with a transmission mechanism 4 and a stripping mechanism 5. The transmission mechanism 4 is located on the left side of the stripping mechanism 5. The transmission mechanism 4 includes a front side plate 11 and a rear side hinged on the U-shaped frame 1. The first transmission roller 41, the second transmission roller 42 and the third transmission roller 43 on the plate 12, the second transmission roller 42 is located above the first transmission roller 41, the third transmission roller 43, and the stripping mechanism 5 includes a The adsorption roller 51 between the side plate 11 and the rear side plate 12, the interior of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com