A kind of preparation method of composite flame-retardant soft PVC resin

A PVC resin and composite flame-retardant technology, which is applied in the field of preparation of composite flame-retardant soft PVC resin, can solve problems such as large market demand, limited antimony metal resources, and rising prices of antimony trioxide, so as to improve the flame-retardant effect , excellent mechanical properties and flame retardant properties, the effect of continuous surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

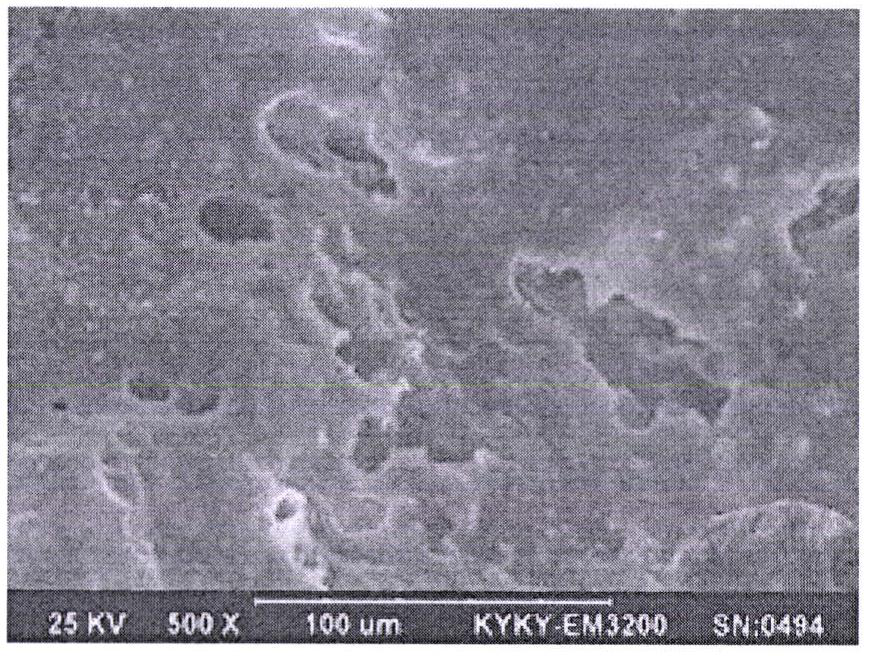

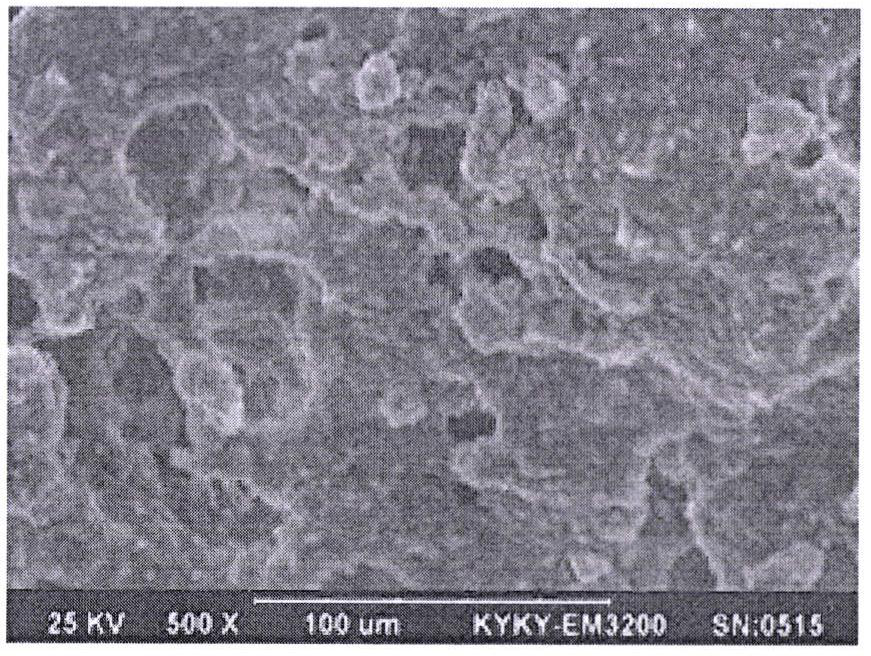

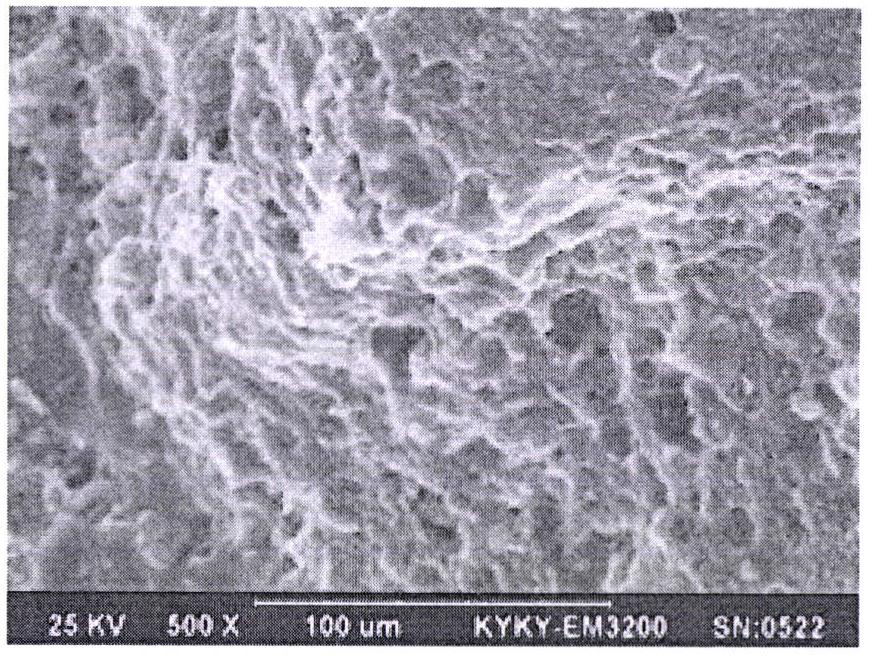

Image

Examples

Embodiment 1

[0023] A preparation method of a composite flame-retardant soft PVC resin, comprising the following steps:

[0024] (1) After montmorillonite and water are mixed according to the mass ratio of 1:2, slowly add ammoniacal liquor with a mass fraction of 25% to it, when the pH of the mixed solution is 8, add ferric nitrate thereto, and After the temperature of the mixture rises to 75°C, heat preservation and continuous stirring for 20 hours, centrifuge, wash the precipitate, and perform drying treatment. The temperature during the precipitation drying treatment is 105°C, and the drying treatment time is 24 hours. Modified montmorillonite, wherein every gram of montmorillonite adds 15mmol ferric nitrate;

[0025] (2) Put the modified montmorillonite in sulfuric acid solution, soak it for 8 hours, dry it, grind it to an average particle size of 200 mesh, sieve it, and finally calcinate it at 550°C for 4 hours to obtain iron Super acid, wherein the temperature during drying treatmen...

Embodiment 2

[0028] A preparation method of a composite flame-retardant soft PVC resin, comprising the following steps:

[0029] (1) After montmorillonite and water are mixed according to the mass ratio of 1:3, slowly add ammoniacal liquor with a mass fraction of 27% to it, when the pH of the mixed solution is 9, add ferric nitrate thereto, and After the temperature of the mixture rises to 78°C, heat preservation and continuous stirring treatment for 22 hours, centrifuge, wash the precipitate, and perform drying treatment. The temperature during the precipitation drying treatment is 110°C, and the drying treatment time is 24 hours. Modified montmorillonite, wherein every gram of montmorillonite adds 20mmol ferric nitrate;

[0030] (2) Put the modified montmorillonite in sulfuric acid solution, soak for 10 hours, dry, grind to an average particle size of 220 mesh, sieve, and finally calcined at 600°C for 5 hours to obtain iron super acid, wherein the drying temperature is 80°C, and the dry...

Embodiment 3

[0033] A preparation method of a composite flame-retardant soft PVC resin, comprising the following steps:

[0034] (1) after montmorillonite and water are mixed according to the mass ratio of 1:5, slowly add the ammoniacal liquor that mass fraction is 28% to wherein, when the pH of mixed solution is 10, add ferric nitrate wherein, will After the temperature of the mixture rises to 80°C, heat preservation and continuous stirring for 24 hours, centrifuge, wash the precipitate, and perform drying treatment. The temperature during the precipitation drying treatment is 115°C, and the drying treatment time is 24 hours. Modified montmorillonite, wherein every gram of montmorillonite adds 25mmol ferric nitrate;

[0035] (2) Put the modified montmorillonite in sulfuric acid solution, soak for 12 hours, dry, grind to an average particle size of 250 mesh, sieve, and finally calcined at 650°C for 6 hours to obtain iron super acid, wherein the temperature during the drying treatment is 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com