A kind of high surface area solid polymer membrane electrode and preparation method thereof

A solid polymer, membrane electrode technology, applied in the field of electrolysis of water, can solve the problems of high electrode cost and low reaction surface area, and achieve the effect of reducing preparation cost, reducing load and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

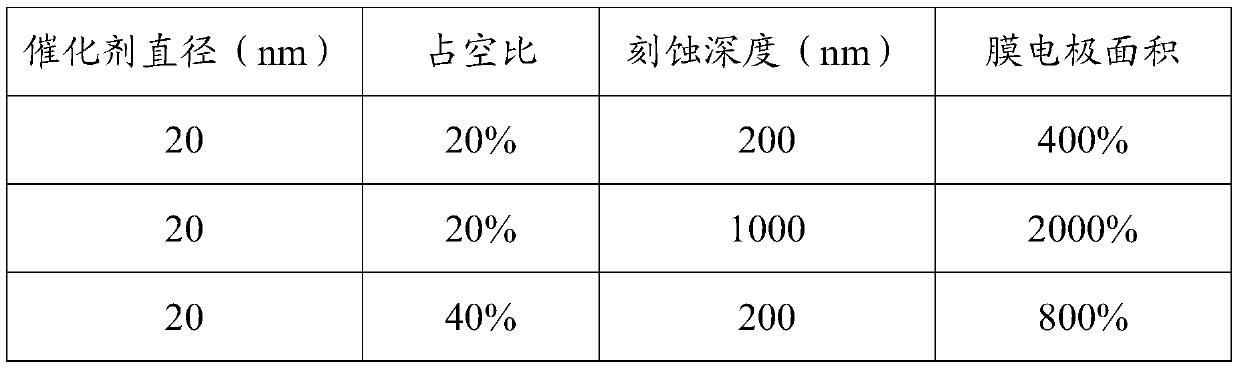

[0049] The present embodiment provides a kind of solid polymer membrane electrode, and its structure comprises, the material is the proton exchange membrane main body 1 of Nafion film and is arranged on some proton exchange columns 2 of this proton exchange membrane main body 1 side, and these several proton exchange columns The material is also Nafion membrane, and the proton exchange column is equipped with IrO 2 -RuO 2 Catalyst particles.

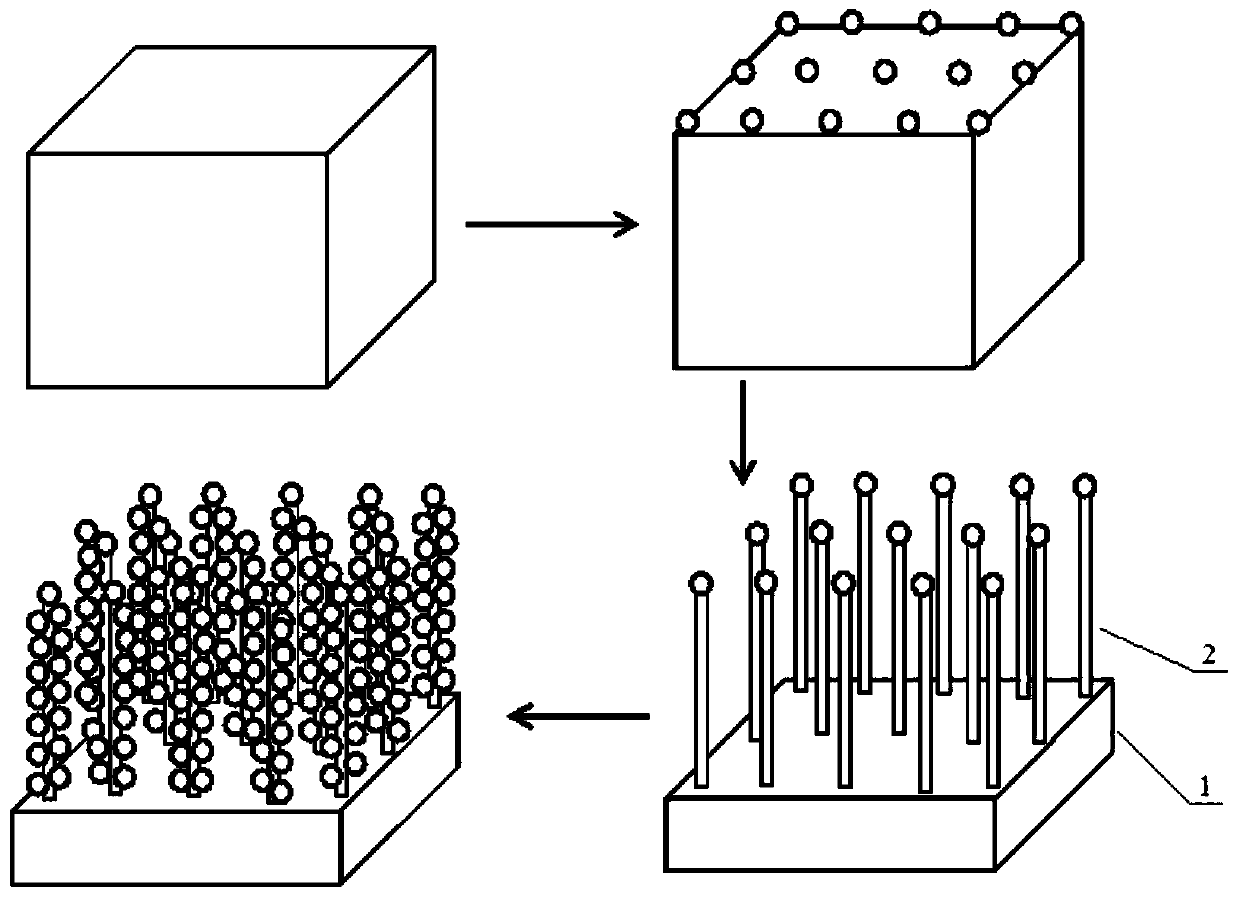

[0050] This embodiment also provides a method for preparing a high surface area polymer membrane electrode, such as figure 1 As shown, it specifically includes the following steps,

[0051] Take the Nafion membrane and coat one surface with RuO 2 The isopropanol dispersion liquid, complete the first catalyst coating, the loading amount is 0.1mg / cm 2 , the duty cycle is about 10%, and then baked at 90°C for 10min.

[0052] Reactive ion etching is used to etch the surface of the membrane coated with the catalyst, using oxygen as the e...

Embodiment 2

[0055] This embodiment provides a method for preparing a high surface area polymer membrane electrode, which specifically includes:

[0056] Take Nafion membrane and coat IrO on one surface 2 The isopropanol dispersion liquid, complete the catalyst coating for the first time, the loading amount is 0.5mg / cm 2 , the duty cycle is about 50% at this time, and then bake at 90°C for 10min.

[0057] The catalyst-coated film surface was etched by a reactive ion etching process, using argon as an etching gas for 4 minutes, and the etching depth was about 200 nm at this time.

[0058] The second catalyst coating is carried out on the surface of the etched membrane, still using IrO 2 isopropanol dispersion, the loading amount is 1mg / cm 2 , and then baked at 90°C for 30min.

Embodiment 3

[0060] This embodiment provides a method for preparing a high surface area polymer membrane electrode, which specifically includes:

[0061] Take the Nafion membrane, and coat the isopropanol dispersion of Ir metal particles on one surface to complete the first catalyst coating, with a loading capacity of 0.2 mg / cm 2 , at this time the duty cycle is about 20%, and then bake at 90°C for 10min.

[0062] Reactive ion etching was used to etch the catalyst-coated membrane surface, using oxygen as the etching gas, and etching for 10 minutes. At this time, the etching depth was 500 nm, and several proton exchange columns with a length of 500 nm were formed.

[0063] Carry out the second catalyst coating on the surface of the membrane after etching, and still use the isopropanol dispersion liquid of Ir metal particles to coat, so that the catalyst particles are attached to the proton exchange column, and the loading capacity of Ir metal particles is 3mg / cm 2 , and then baked at 90°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com