One-hole multi-pore-water-pressure-gauge burying structure and method

A technology of pore water pressure gauge and water pressure gauge, which is applied in the direction of infrastructure engineering, on-site foundation soil survey, construction, etc., can solve the problems of increasing cost, slow release speed of pore pressure gauge, complicated process, etc., so as to prevent upper and lower connection. , to ensure smooth water seepage and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

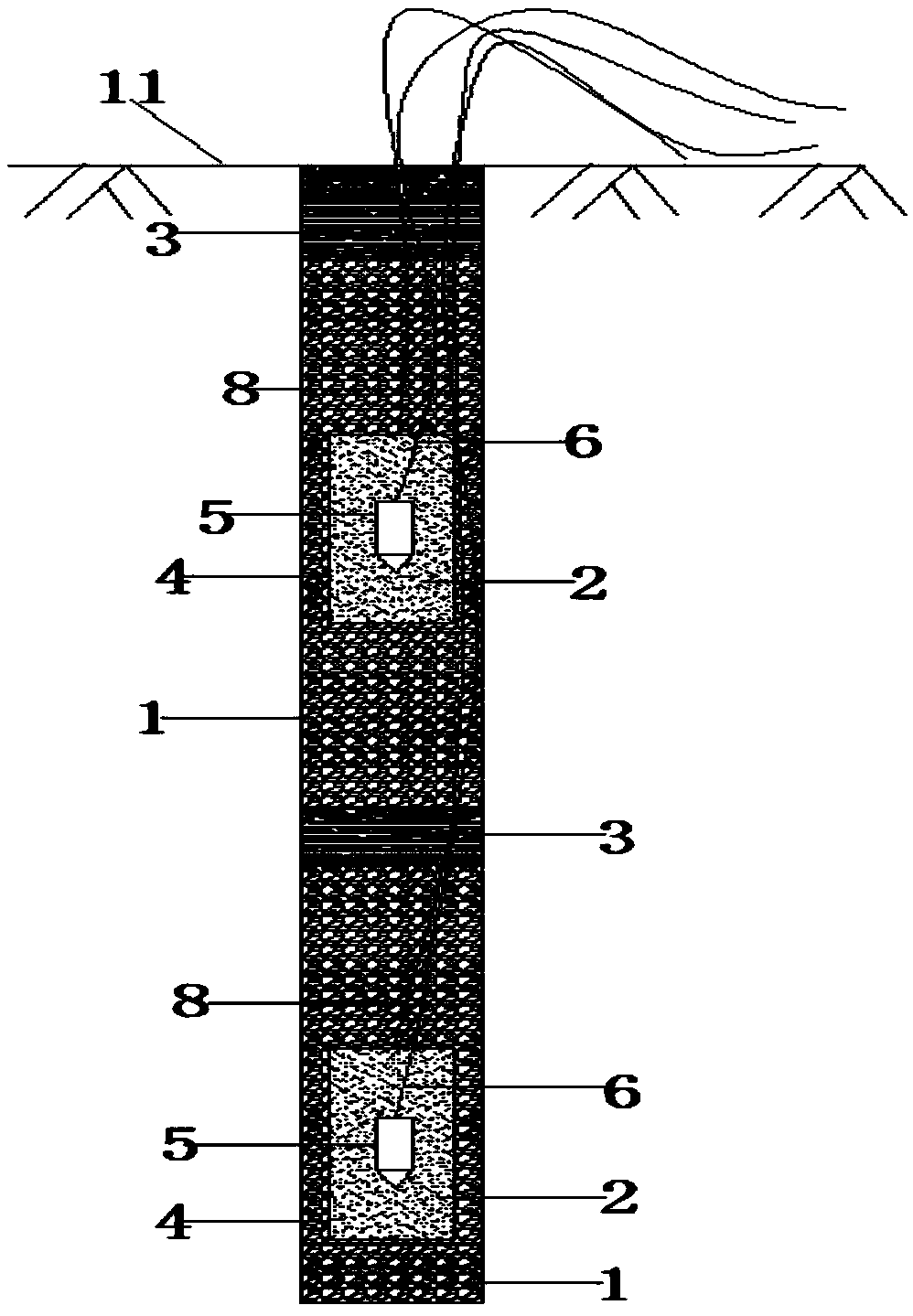

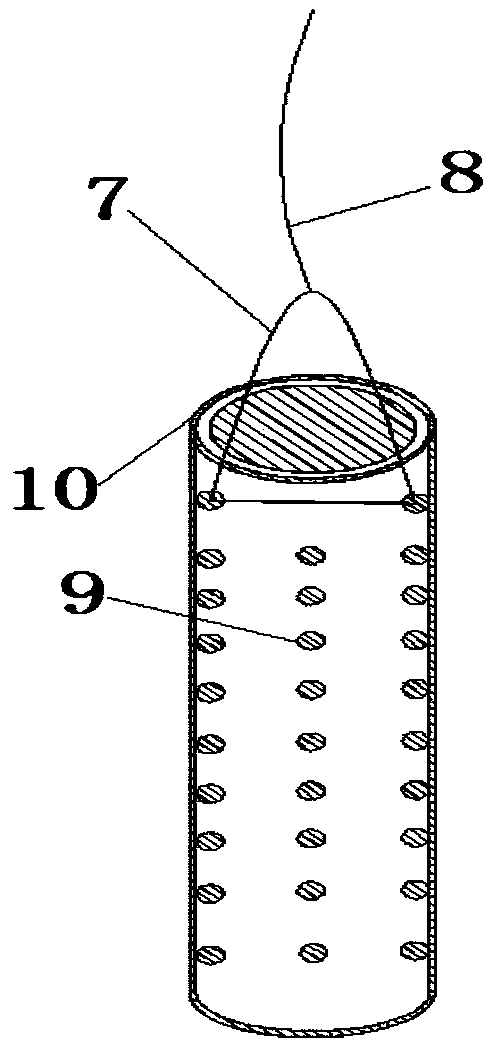

[0027] Such as figure 1 , figure 2 As shown, an embedded structure of a multi-hole pore water pressure gauge includes a pre-embedded pipe 4, a plurality of water permeable holes 9 are arranged on the side wall of the pre-embedded pipe 4, a geotextile layer 10 is wrapped on the outside of the pre-embedded pipe 4, and the pre-embedded pipe 4 4 is provided with a pore water piezometer 5 that does not fit the inner wall of the embedded pipe 4, and fine sand 2 is provided between the inner wall of the embedded pipe 4 and the pore water piezometer 5; the embedded pipe 4 is wrapped with a geotextile layer 10 It is arranged in the pre-buried hole of the rock and soil to be measured, and a sealing layer 3 is arranged between the pre-buried pipe 4 and the pre-buried hole of the rock and soil to be measured,

[0028] The sealing layer 3 is a clay layer;

[0029] There is a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com