Variable camshaft and engine adopting camshaft

A camshaft and engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as inconvenient control and complex structure, and achieve the effects of good coordination, improved reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment proposes a variable camshaft with simple structure and easy processing and an engine using the camshaft. The engine can use the camshaft to adjust the valve lift, so as to achieve the purpose of improving fuel economy and power.

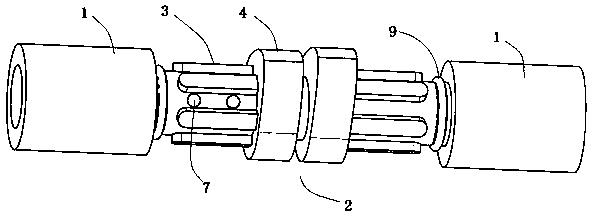

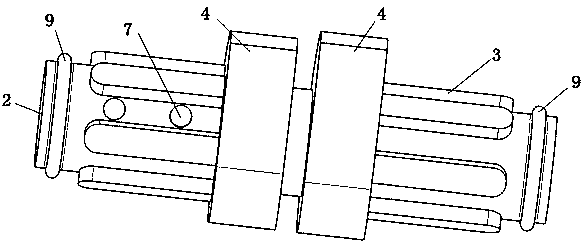

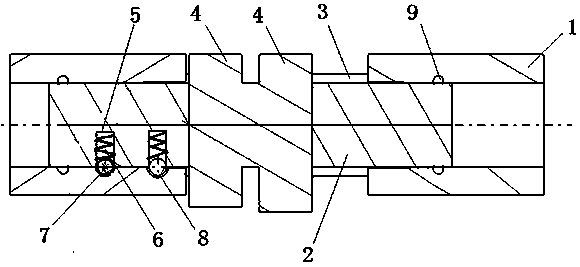

[0024] Such as figure 1 , 2 As shown, the variable camshaft of this embodiment is composed of the hollow shaft 1 on both sides and the main shaft 2 in the middle, the two sides of the main shaft 2 extend into the hollow shaft 1 on the corresponding side, and 1 is movably connected by spline fit, wherein the shaft body of the main shaft 2 is provided with an external spline 3, and the inner wall of the hollow shaft 1 is provided with an internal spline; the middle part of the shaft body of the main shaft 2 is provided with two corresponding The cam 4 of the stroke curve; the main shaft 2 and the hollow shaft 1 on the left are provided with a self-locking mechanism that cooperates with each other so that the position of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com