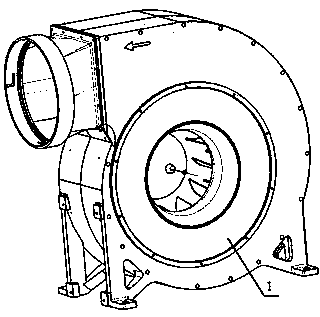

Collector air inlet device of centrifugal fan

A centrifugal fan and current collector technology, which is applied to the components of the pumping device for elastic fluids, machines/engines, mechanical equipment, etc., to achieve the effects of convenient use, simple structure, and easy processing and forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

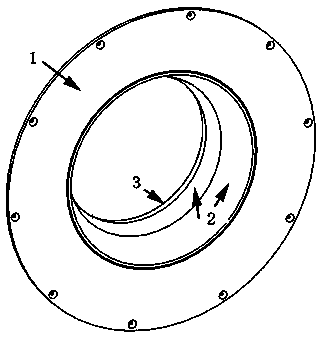

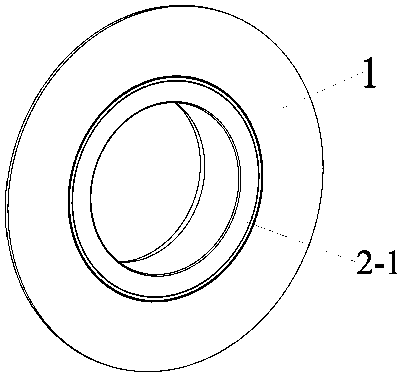

[0035] like image 3 As shown, the diversion unit is designed as a triangular arc structure, such as Figure 4 The cross-section of the entire circle of air guide unit shown in the figure is completely connected tangentially to the arc surface, and is integrated by screws or riveting. The air flow passing surface of the arc surface and the triangular arc unit is a plane, and the arc is 0°, close to the air inlet The area is flush with the end face of the collector.

Embodiment 2

[0037] like Figure 5 As shown, the guide unit is designed as a sawtooth structure, with several sawtooth surfaces evenly distributed in the same circumferential direction. The sawtooth surface is perpendicular to the axis of the air inlet of the centrifugal fan and flush with the end face of the collector. The two are connected by screws or rivets. The sawtooth angle and sawtooth height can be adjusted according to the noise characteristics of the centrifugal fan; in this example, the sawtooth height is 10mm, and the sawtooth angle is 30 o , the distance between sawtooth and sawtooth is 20mm, the number of sawtooth is 22, and the thickness of sawtooth is 5mm.

Embodiment 3

[0039] like Image 6 As shown, the guide unit is designed as a concave groove structure, and several grooves are evenly distributed in the same circumferential direction. The angle formed by the length direction of the groove unit and the axial direction of the air inlet of the centrifugal fan is 10°. The two are connected by screws or Rivet connection. The groove depth, groove width, and angle between the groove direction and the axial direction of the fan inlet can be adjusted according to the noise characteristics of the centrifugal fan; The pitch of the trough is 20mm, and the number of trough units is 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com