Portable onsite converter valve tester

A tester and converter valve technology, which is applied in the direction of the measuring device casing, casters, wheels, etc., can solve the problems of overall equipment failure, poor ground flatness, storage, etc., and achieve the effect of improving the passing performance and reducing the longitudinal height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

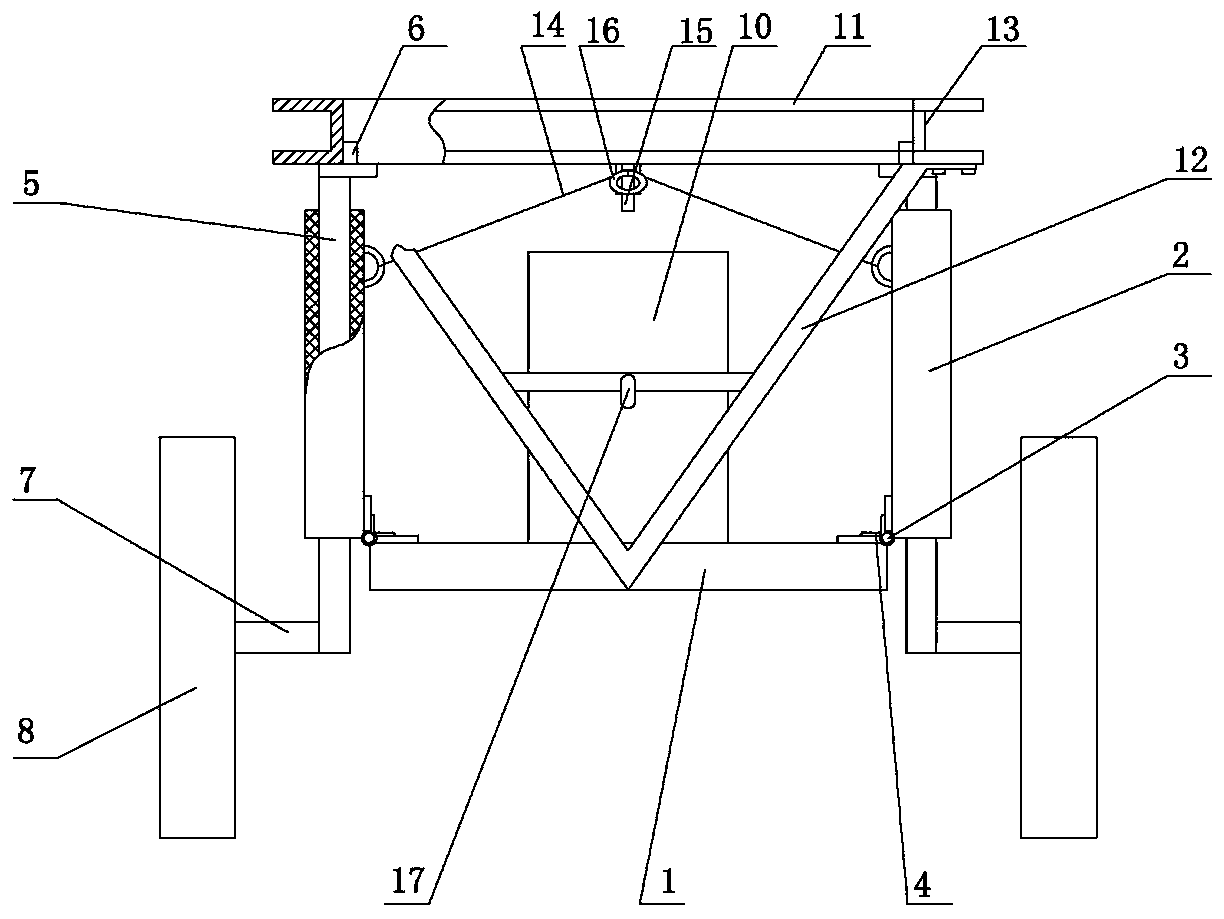

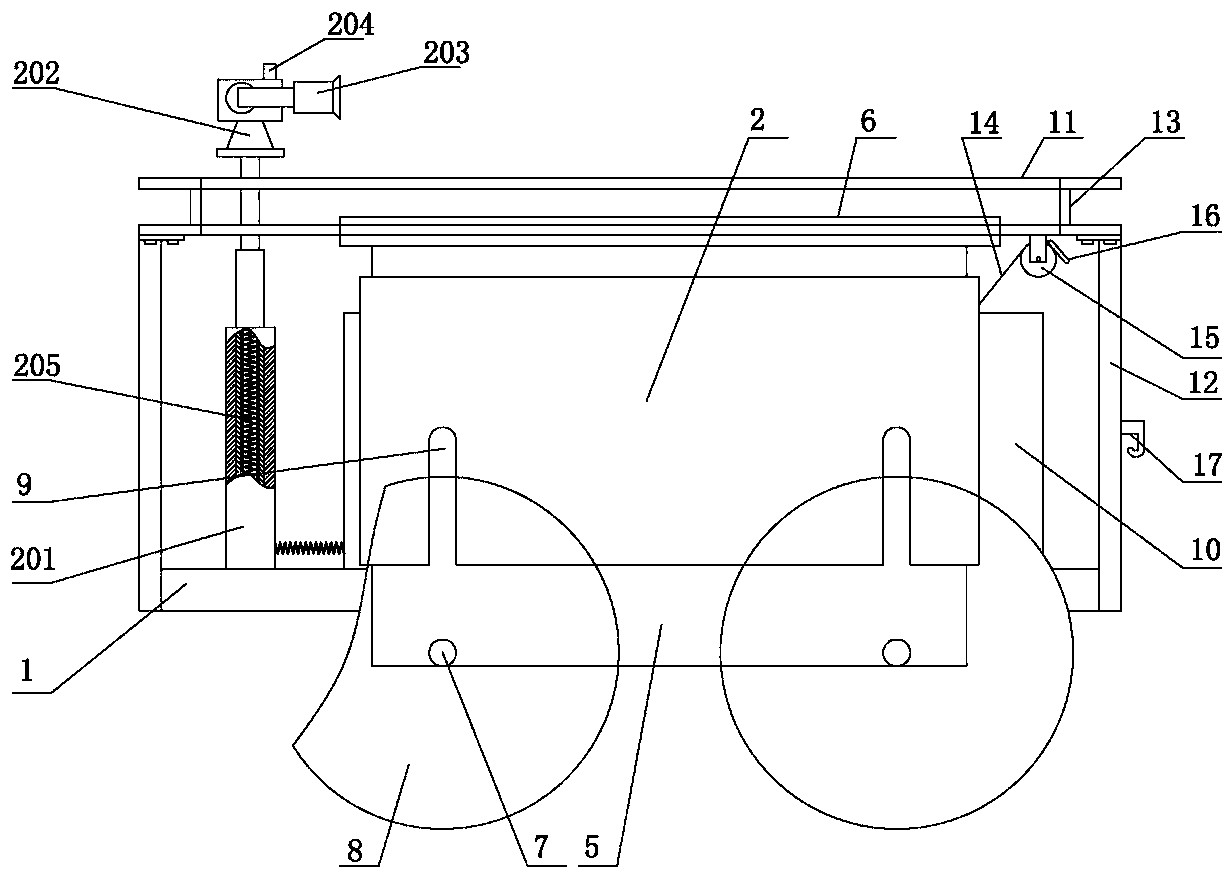

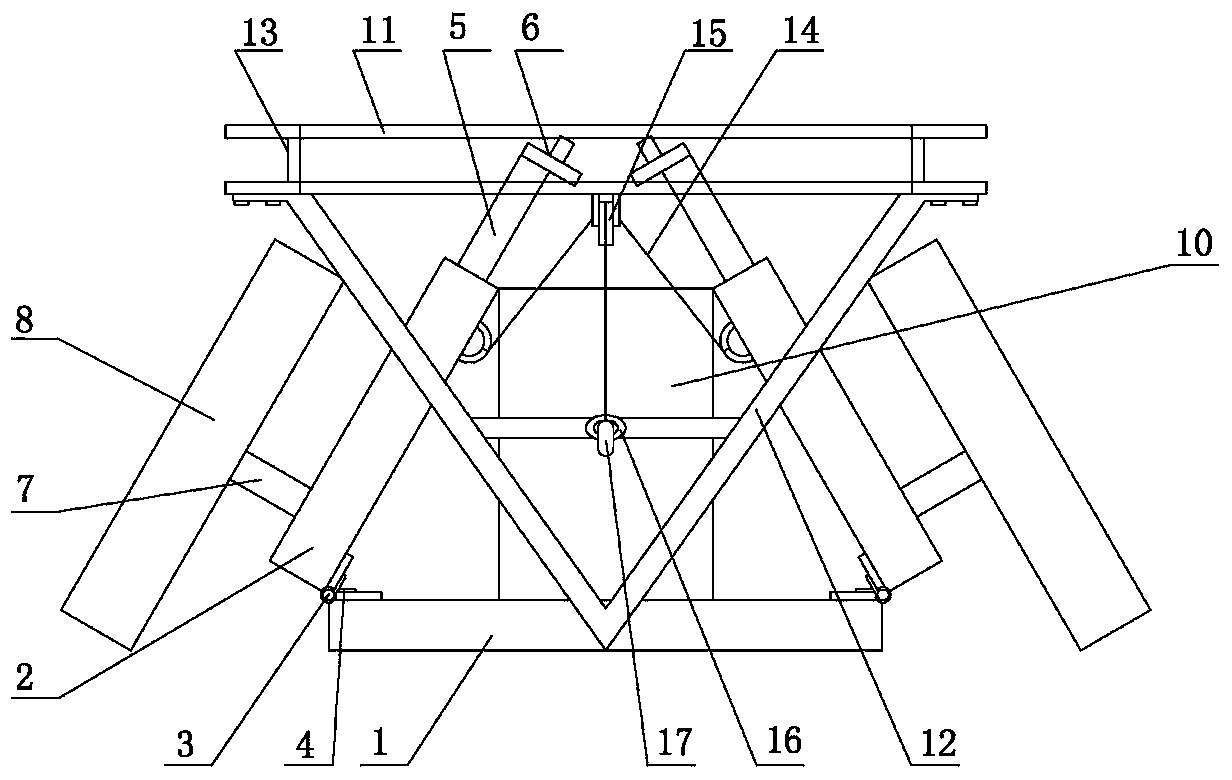

[0016] The portable on-site converter valve tester described in the present invention includes a converter valve tester 10, and a tester base plate 1 is provided under the converter valve tester 10, and the tester base plate 1 is rectangular. A rectangular sliding sleeve 2 is respectively provided on both sides of the tester base plate 1, and the rectangular sliding sleeve 2 is arranged along the length direction of the tester base plate 1, and each rectangular sliding sleeve 2 is connected with the tester base plate 1 through a hinge shaft 3, Each hinge shaft 3 is provided with a torsion spring 4, and the torsion spring 4 makes the corresponding rectangular sliding sleeve 2 always have a tendency to rotate outward, and each rectangular sliding sleeve 2 is provided with a rectangular sliding plate 5 that can slide up and down inside it. , the top of the rectangular slide 5 is provided with a positioning block 6, the positioning block 6 can fall to the top of the rectangular sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com