a blind brick

A technology of blind roads and bricks, applied in roads, roads, buildings, etc., can solve the problems of blind roads that are easy to hide dirt, inconvenient cleaning, and sore feet, so as to reduce secondary pollution, improve utilization rate, and reduce occupied time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

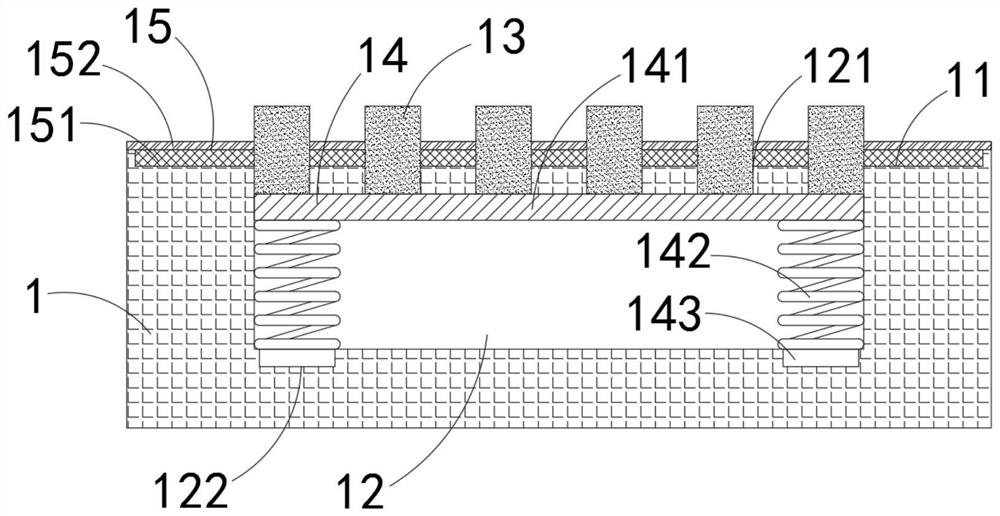

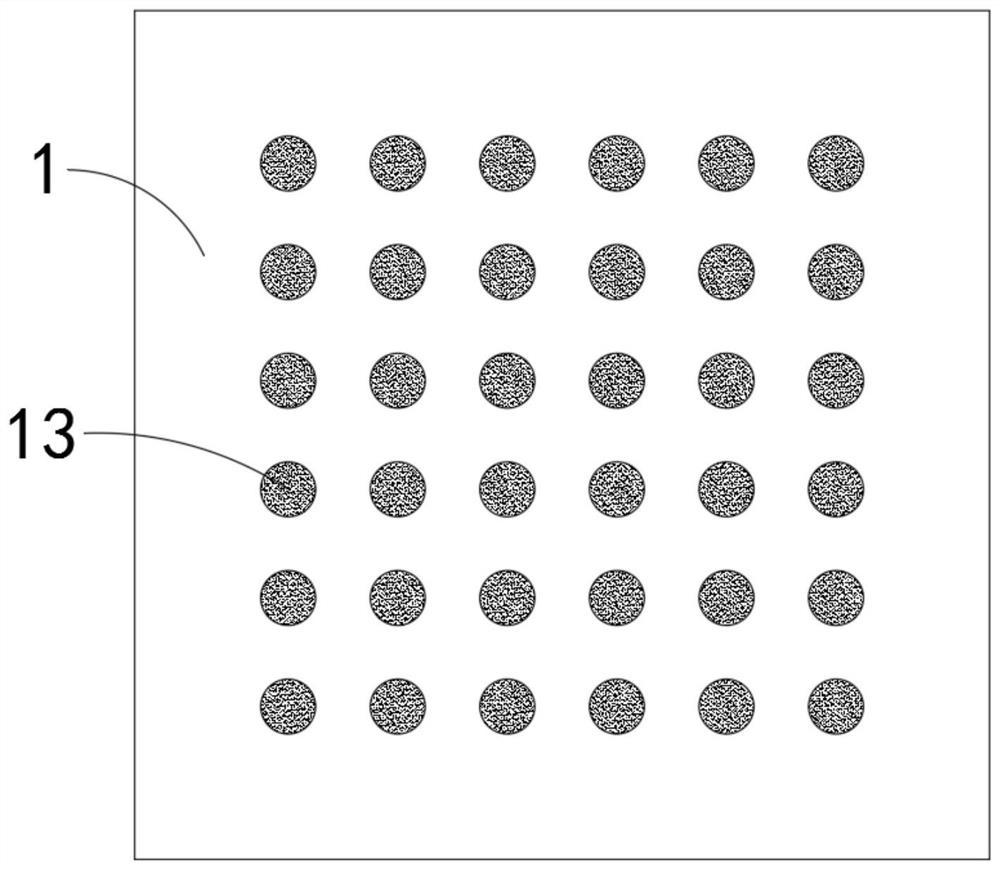

[0046] Such as Figure 1-3 Shown, a kind of tactile paving brick, comprises brick body 1, is provided with in brick body 1:

[0047] Placement groove 11, the placement groove 11 is arranged on the upper surface of the brick body 1;

[0048] Placement cavity 12, the placement cavity 12 is set in the middle of the brick body 1, the top surface of the placement cavity 12 is provided with a plurality of through holes 121, and the four corners of the bottom surface of the placement cavity 12 are provided with installation grooves 122;

[0049] The protruding columns 13 correspond to the through holes 121, and the protruding columns 13 are slidingly and sealingly connected in the through holes 121. It should be noted that a plurality of protruding columns 13 are distributed on the surface of the brick body 1 in an array. It is consistent with the raised distribution of the existing tactile walkway, which is convenient to use, and the raised column 13 can be made of rubber material ...

Embodiment 2

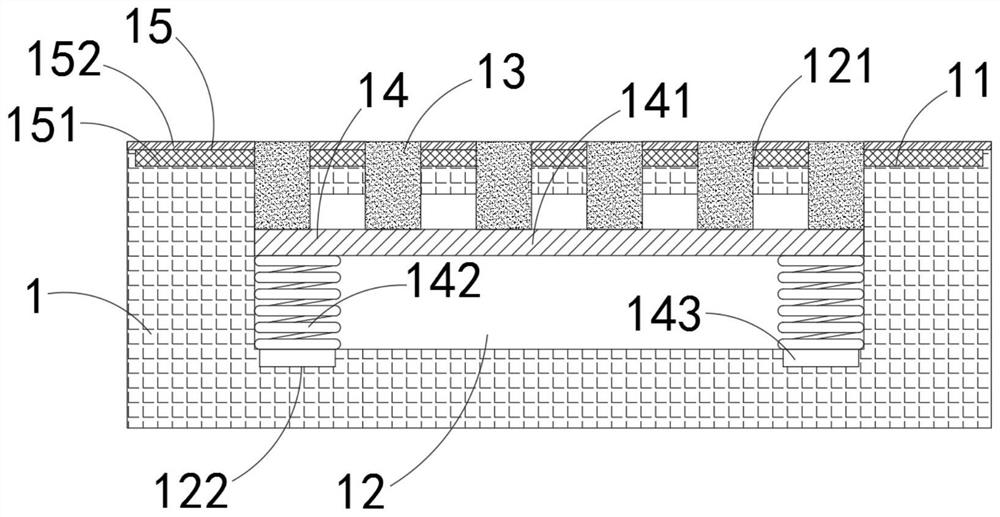

[0063] Such as Figure 4-6 As shown, the difference between this embodiment and Embodiment 1 is that a water spray mechanism 16 is provided in the placement cavity 12, and the water spray mechanism 16 includes:

[0064] Elastic bellows 161, elastic bellows 161 can be made of rubber material, can freely expand and contract along its axial direction, clean water is filled in elastic bellows 161, the upper and lower sides of elastic bellows 161 are respectively connected with the lower surface of lifting plate 141 and the placement cavity The bottom surface of 12 is fixedly connected;

[0065] One-way drain pipe 162, the one-way drain pipe 162 is composed of a drain pipe and a first one-way valve, the first one-way valve only allows liquid to be sprayed out from the elastic bellows 161, and a plurality of one-way drain pipes 162 run through and are fixedly connected On the top surface of the placement chamber 12, the part of the one-way drain pipe 162 located in the placement ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com