A Continuous Electrostatic Monitor for Powder

A monitor and electrostatic detection technology, which is applied in the direction of instruments, measuring devices, and measuring electrical variables, etc., can solve the problems of powder mass deviation and the reduction of charge-to-mass ratio accuracy of electrostatic monitors, and achieve stable control, improved monitoring response speed, Effects of improved service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

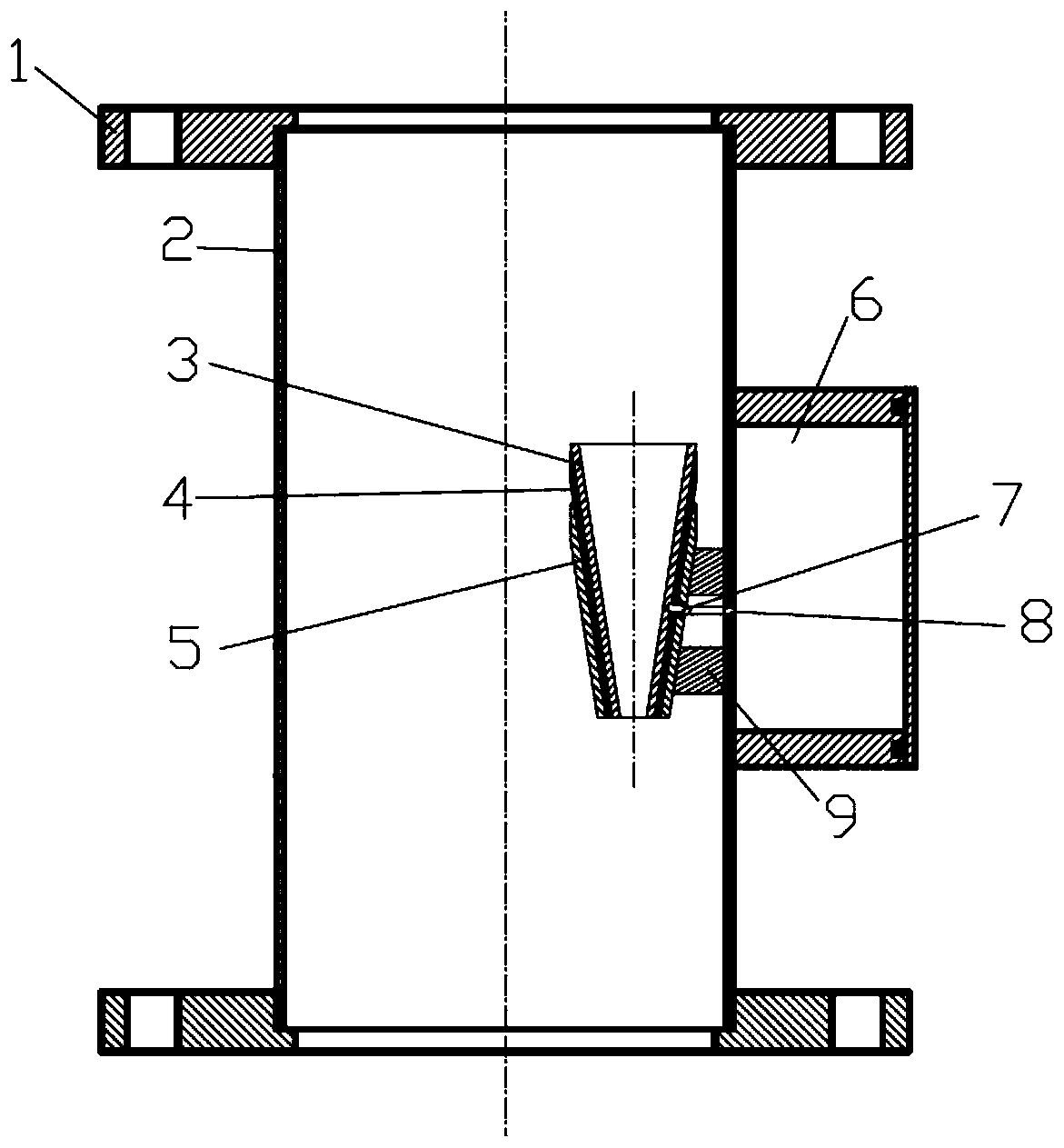

[0026] like figure 1 As shown, a powder electrostatic continuous monitor consists of a connecting flange 1, an outer cylinder 2, an inner cup of a sampling cup 3, an insulating layer 4, an outer cup of a sampling cup 5, an explosion-proof chamber 6, an inner cup electrical lead-out structure 7, and a sampling cup The support member 9 is composed.

[0027] There are two connecting flanges 1, which are fixedly connected to both ends of the outer cylinder 2; the outer cylinder 2 is a metal cylinder with an open cylindrical structure, and the side wall of the outer cylinder 2 is provided with an electrical outlet hole 8 for the outer cylinder; The inner cup 3 of the sampling cup, the insulating layer 4, and the outer cup 5 of the sampling cup form an inverted cone-shaped sampling cup, which is located inside the outer cylinder 2 and is close to the edge of the pipe. The insulating layer 4 is located outside the inner cup 3 of the sampling cup, and the outer cup 5 of the sampling c...

Embodiment 2

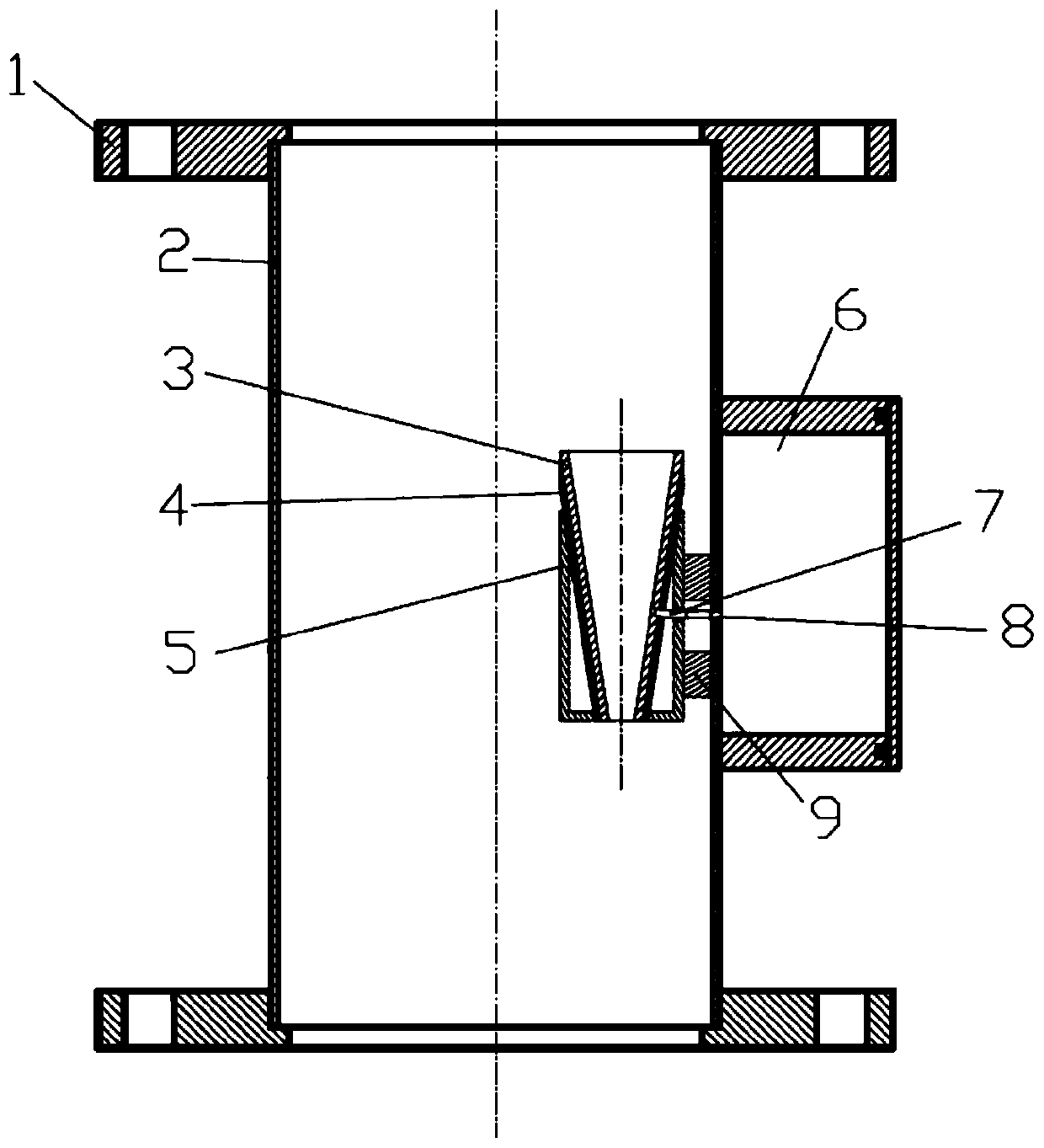

[0032] like figure 2 As shown, the structure of embodiment two is similar to that of embodiment one, the difference is that the outer cup 5 of the sampling cup has the same diameter as the inlet edge of the inner cup 3 of the sampling cup, and the outer cup wall of the outer cup 5 of the sampling cup is a cylindrical surface of equal diameter .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com