Method of adopting semi-continuous fermentation technology to produce pyrroloquinoline quinone

A technology of pyrroloquinoline quinone and fermentation technology, which is applied in the field of fermentation engineering, can solve the problems of short maintenance time, limit the fermentation output of PQQ, and spend a lot of time, and achieve the effect of maintaining volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Shake flask seed culture of embodiment 1 PQQ

[0036] Prepare the seed bottle medium according to the basic medium formula, the seed bottle volume is 30ml / 250ml, after sterilization, add 0.3ml of methanol to each bottle before inoculation.

[0037] From the inoculation of the slant strain to the seed bottle, the seed bottle cultivation process: cultivation temperature 30°C, shaker speed 250rpm, cultivation time 48h, cultured shake flask seed solution OD 600 The value is 0.92.

Embodiment 2

[0038] Shake flask fermentation of embodiment 2 PQQ

[0039] Prepare fermentation bottle culture medium according to the formula of the basic medium, and the volume of the fermentation bottle is 30ml / 250ml. After sterilization and before inoculation, add 0.6ml of methanol to each bottle.

[0040] The shake flask seed liquid cultivated according to the method in Example 1 was transferred to the fermentation bottle, and the fermentation bottle cultivation process: the transfer amount was 10% v / v, the cultivation temperature was 30° C., the shaking table speed was 250 rpm, and the cultivation time was 5 days. The fermentation units of the three fermentation bottles were 9.2mg / L, 11.7mg / L, and 13.6mg / L, respectively, with an average of 11.5mg / L.

[0041] During the cultivation process of PQQ's production strain, Phytophagy microbes, the pH of the fermentation broth drops rapidly, and gradually deviates from the optimum growth pH 6.90. Because it is inconvenient to supplement ammon...

Embodiment 3

[0042] The fed-batch fermentation experiment of embodiment 3 PQQ

[0043] The fermentation equipment used in this example is a set of dual fermentation small test tank equipment, the volume of the seed tank is 5L, and the volume of the fermenter is 50L.

[0044] Seed tank seed culture: the formula of the seed tank culture medium is the same as that of the basic medium formula, and the seed tank filling capacity is 3L / 5L. After sterilization, add 60ml of methanol before inoculation, and then shake the seeds cultivated according to the method in Example 1 The solution was inoculated into the seed tank according to the inoculation amount of 1.0% (30ml). The seed tank cultivation process: the cultivation temperature was 30°C, the ventilation rate was 0.8vvm, the stirring speed was 100-300rpm, the stirring speed was related to the dissolved oxygen (DO), and the control DO≥30 %, culture time 48h, cultured seed solution OD 600 The value is 0.95.

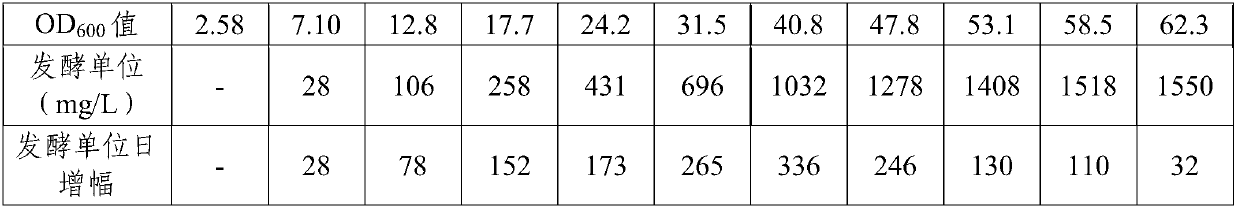

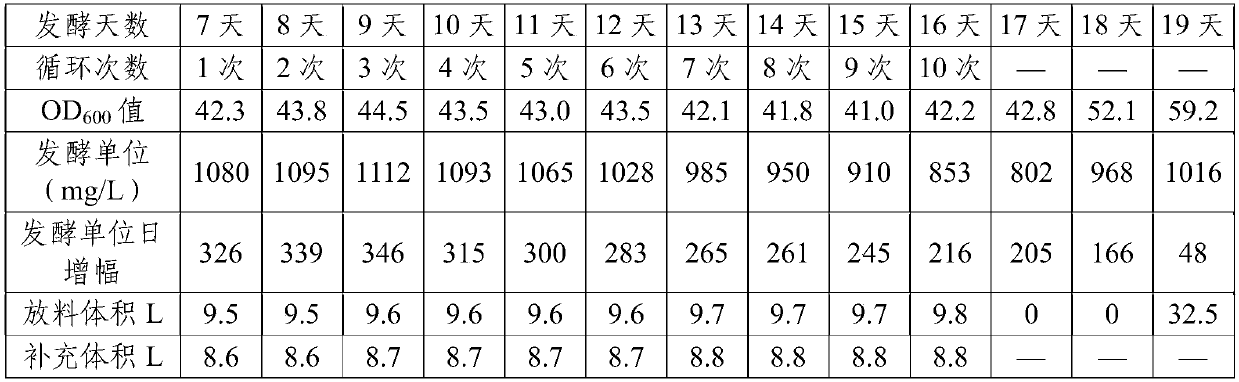

[0045] Fermentation tank fed-batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com