Full-automatic static elimination system

A static elimination and fully automatic technology, applied in the direction of static electricity, electrical components, measuring electrical variables, etc., can solve the problems of over-charge of silo charge, high residual electrostatic charge, and potential safety hazards, so as to improve service life and reliability , The effect of increasing the convergence speed of power dissipation and improving the monitoring response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

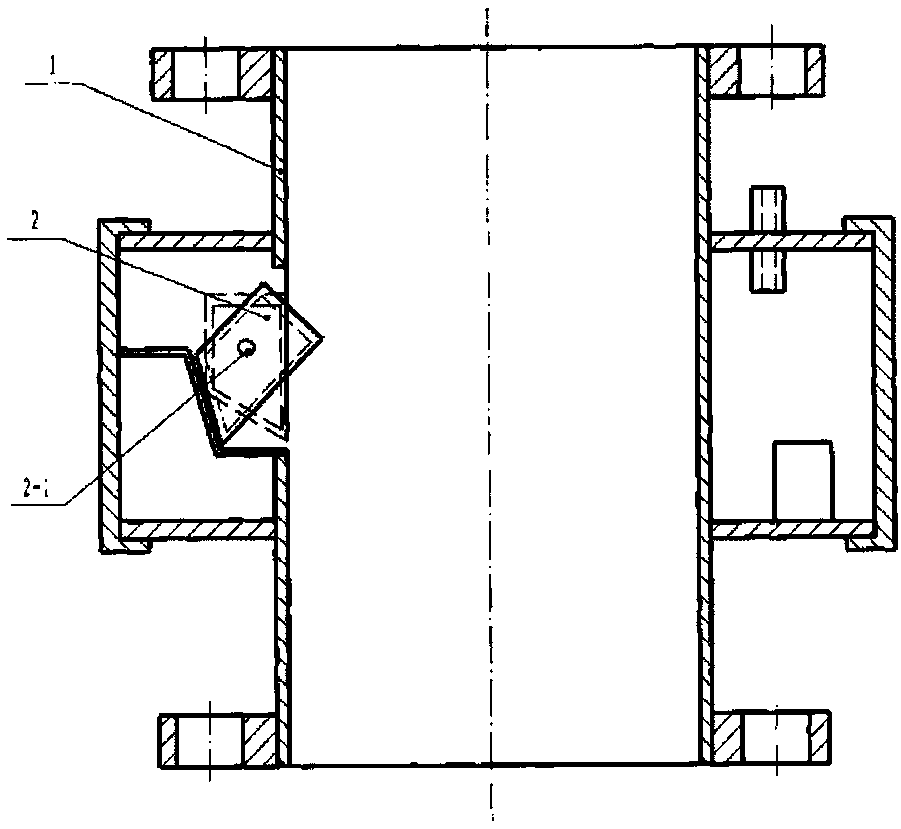

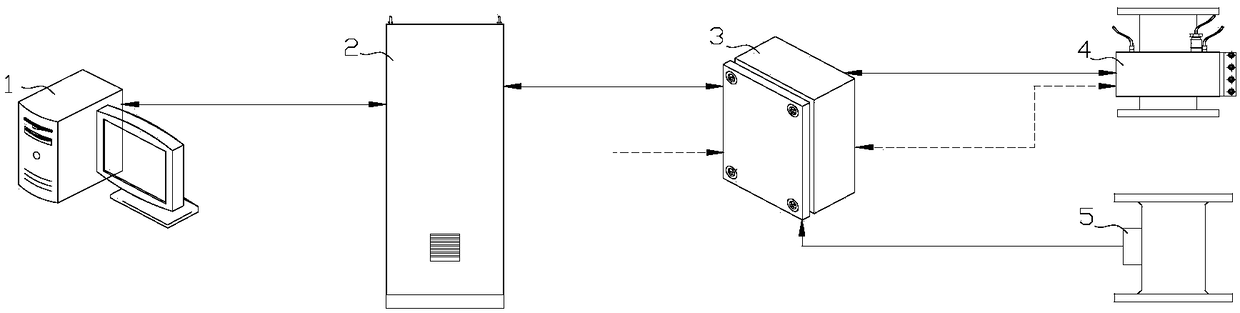

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0027] Such as figure 2 As shown, the fully automatic static elimination system is composed of a workstation 1, a PLC control cabinet 2, a sub-control box 3, a consumer 4, and a monitor 5.

[0028] The consumer 4 is a bipolar ion wind static eliminator, which receives the control signal from the PLC control cabinet 2, and outputs positive ion wind or negative ion wind with controllable intensity; the material conveying state detector is configured in the consumer 4, It can be judged whether there is a material transfer. The consumer 4 is a positive pressure explosion-proof structure, has obtained explosion-proof certification, and accepts the instrument air that has been depressurized from the sub-control box 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com