Metal mixer event band-type brake limit control device

A technology of control device and mixed iron furnace, applied in the direction of circuit device, electrical program control, sequence/logic controller program control, etc., can solve the problems of no mechanical protection, large mechanical impact, molten iron dumping, etc., to reduce property Loss, avoiding personal injury and shortening the effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments provided by the present invention will be described in detail below.

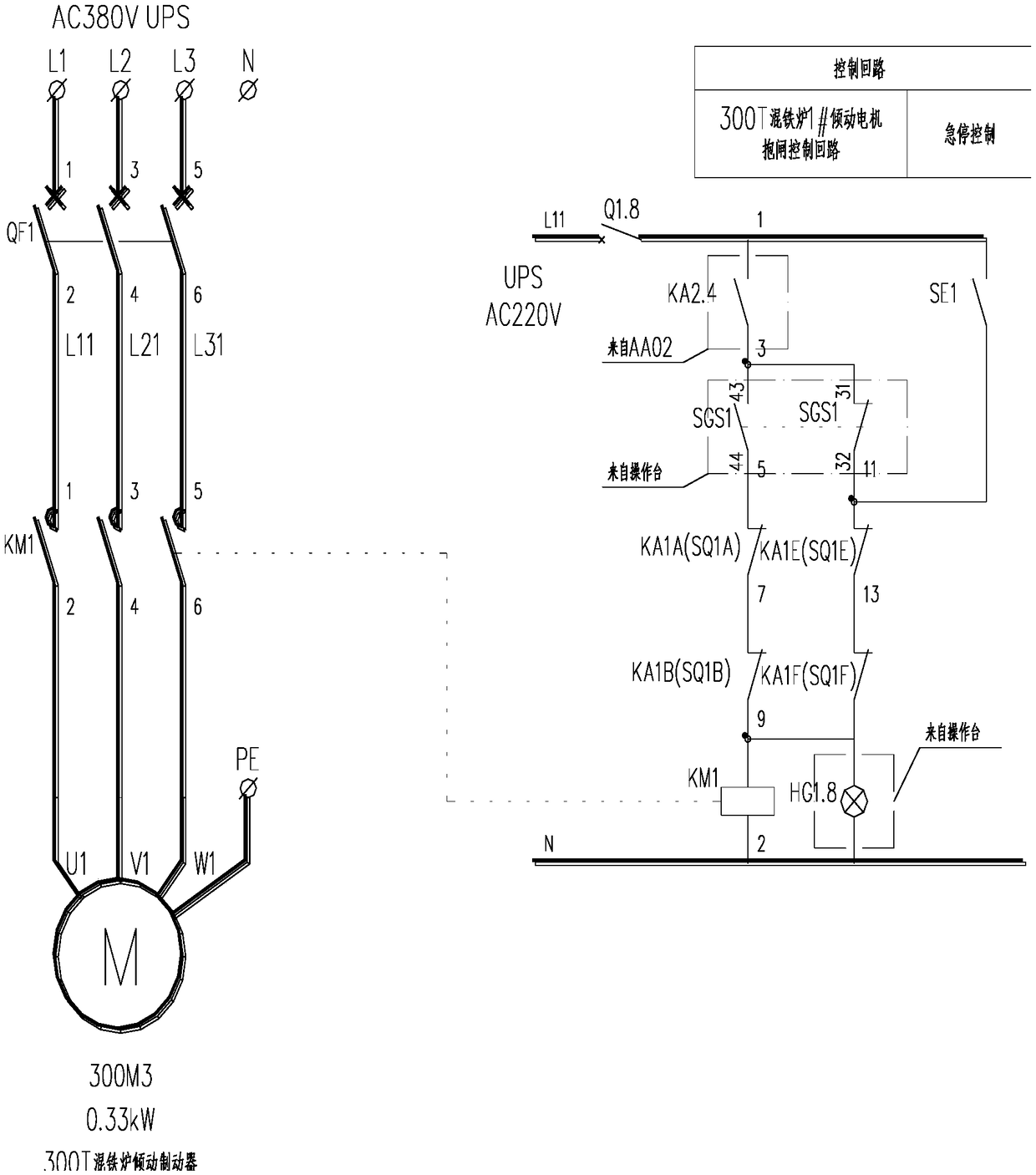

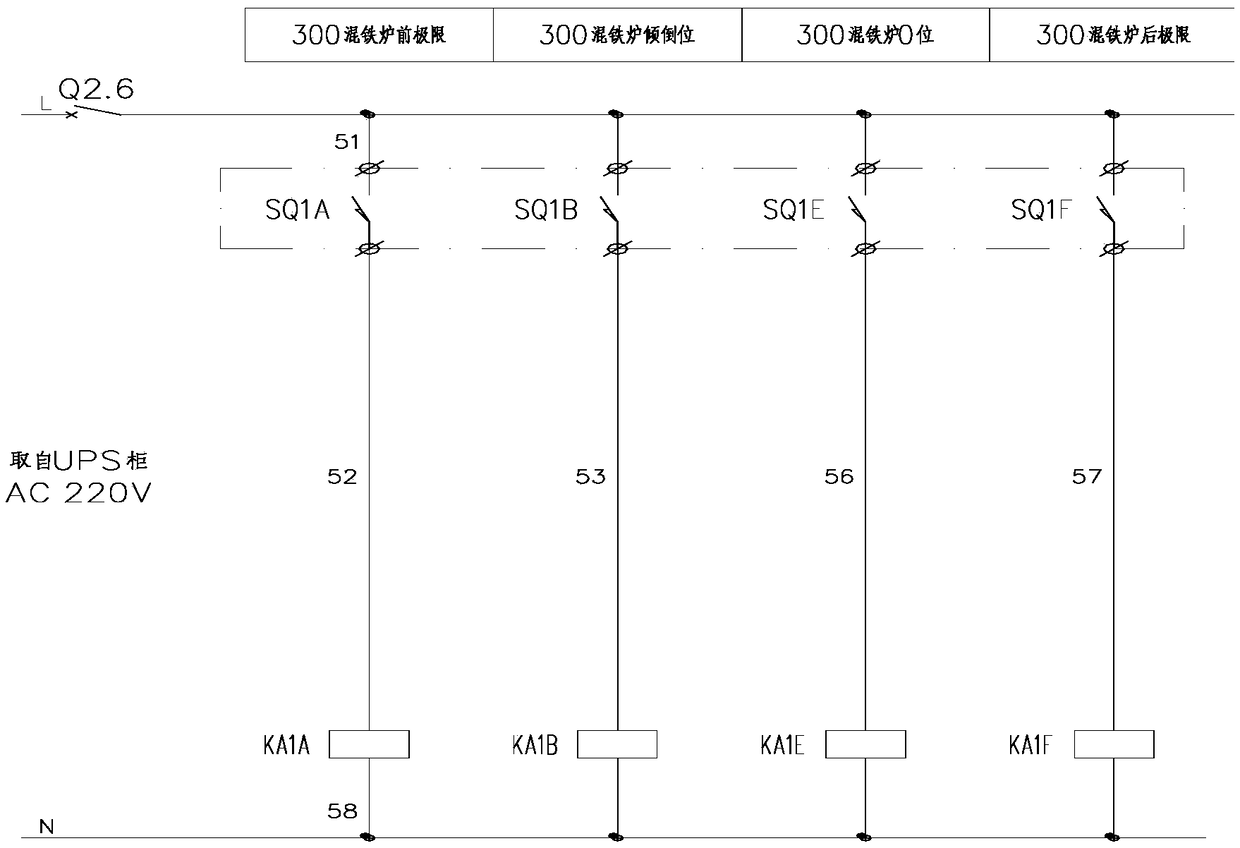

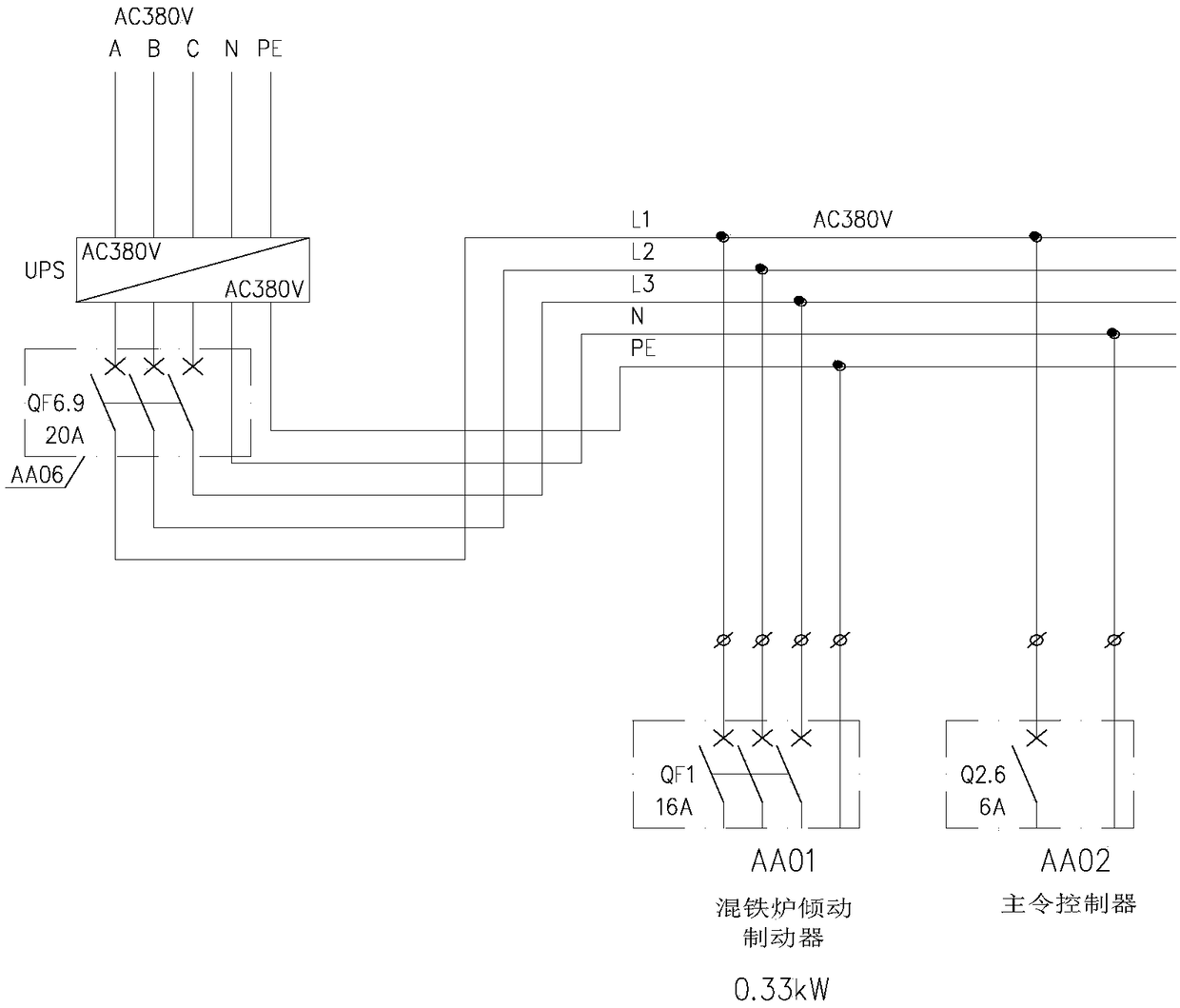

[0026] Such as figure 1 As shown, an emergency lock limit control device for a mixed iron furnace includes a contactor KM1, and also includes a UPS power supply, an operating handle SGS1, an emergency stop switch SE1, and a master command controller for a mixed iron furnace. The controller includes the front limit position SQ1A of the iron mixing furnace, the dumping position SQ1B of the iron mixing furnace, the original position SQ1E of the iron mixing furnace and the rear limit position SQ1F of the iron mixing furnace.

[0027] The upper end of the main contact of the contactor KM1 is connected to the UPS power supply, and the lower end is connected to the motor coil of the brake of the tilting motor of the mixed iron furnace.

[0028] The lower end of the coil of the contactor KM1 is connected to the N end of the UPS power supply, and the upper end is connected to the L e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com