An industrial power load decomposition method of industrial electric load based on matrix decomposition

A technology for industrial power consumption and load decomposition, applied in the field of power management, can solve problems such as the lack of a standardized load decomposition method, and achieve the effect of scientific reference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

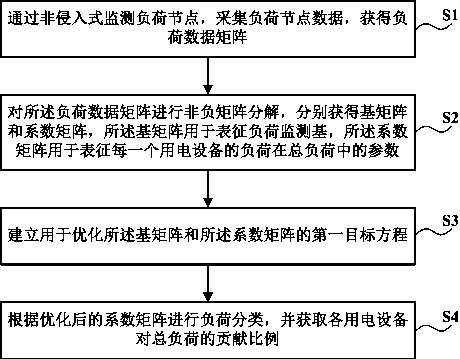

[0040] Please refer to figure 1 As shown, the embodiment of the present invention provides a matrix decomposition-based industrial power load decomposition method, which can be used for load decomposition in non-intrusive power load monitoring, including the following steps:

[0041] Step S1, through non-intrusive monitoring of load nodes, collecting load node data, and obtaining a load data matrix;

[0042] Step S2, performing non-negative matrix decomposition on the load data matrix to obtain a base matrix and a coefficient matrix respectively, the base matrix is used as a load monitoring base, and the coefficient matrix is used to represent the load of each electrical equipment in the total load parameters in

[0043] Step S3, establishing a first objective equation, optimizing the basis mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com