Forward interpolation method for angle sensor and rotary encoder

A rotary encoder and angle sensor technology, applied in the field of semiconductors, can solve the problems of not meeting the requirements of accuracy and real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

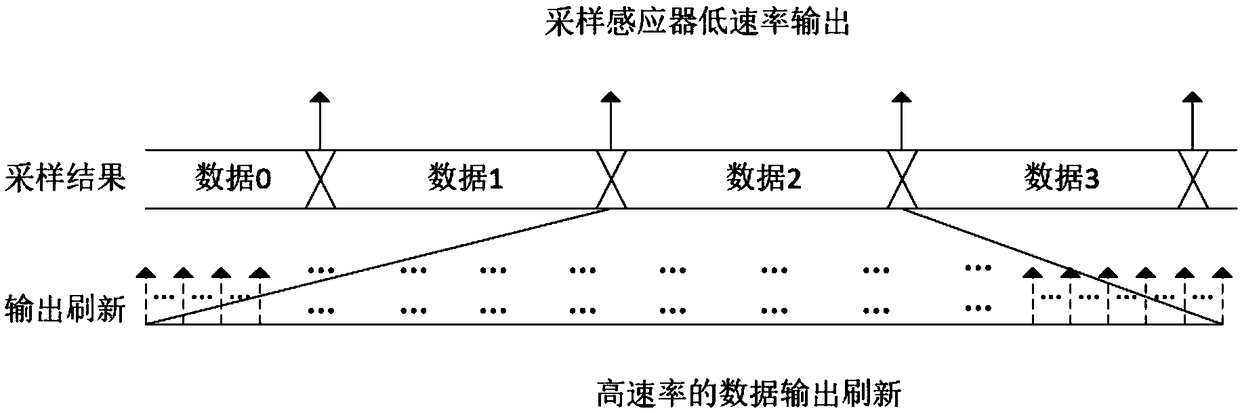

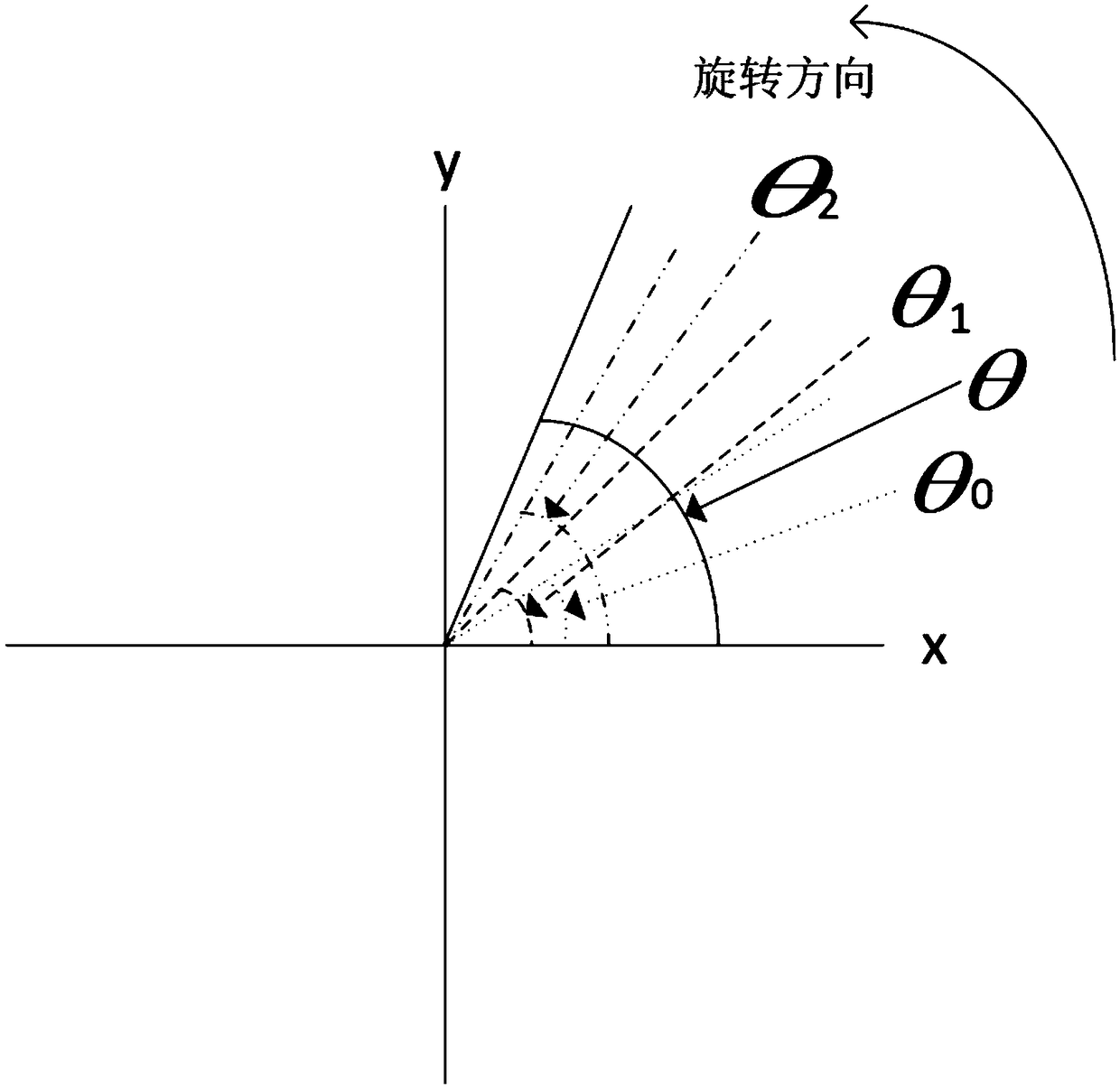

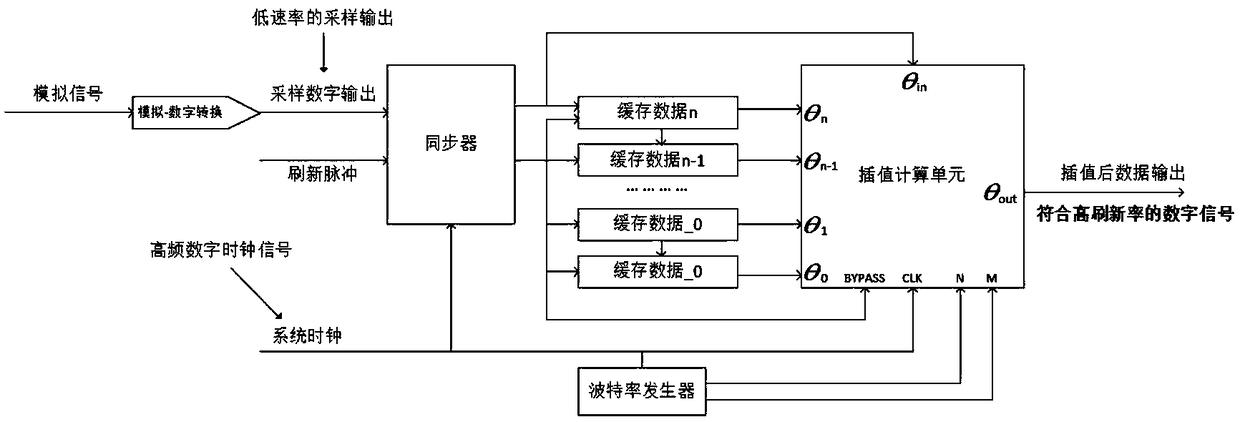

[0091] see figure 1 , the present invention discloses a forward interpolation method of an angle sensor and a rotary encoder based on the principle of discrete rotational inertia. Angle changes within. The method includes: according to the inertia theorem of rigid body motion, assuming that the rigid body rotates in a short period of time to follow the principle of uniform acceleration motion (corresponding to the following step S1); on the basis of the angular position information obtained at the latest several sampling moments Calculate to obtain the angular velocity and angular acceleration value of the predicted starting position (corresponding to the following step S2); according to the angular information, angular velocity information and angular acceleration information of the starting position, perform forward interpolation prediction calculation under the requirements of the output frequency (corresponding to The following steps S3 and S4).

[0092] Described method...

Embodiment 2

[0124] The difference between this embodiment and Embodiment 1 is that in this embodiment, the present invention discloses a forward interpolation method of an angle sensor and a rotary encoder based on the principle of discrete rotational inertia. The angle information of the object at the time is used to predict the angle change of the object in the next period of time. The method includes: according to the inertia theorem of rigid body motion, assuming that the rigid body rotates in a relatively short period of time to follow the principle of uniform acceleration motion; calculate on the basis of the angular position information obtained at the latest several sampling moments, and obtain the predicted starting position The angular velocity and angular acceleration values; according to the angle information, angular velocity information and angular acceleration information of the starting position, the forward interpolation prediction calculation is performed under the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com