Grain boundary structure searching method based on defect properties and multiscale simulation

A search method, multi-scale technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as changing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

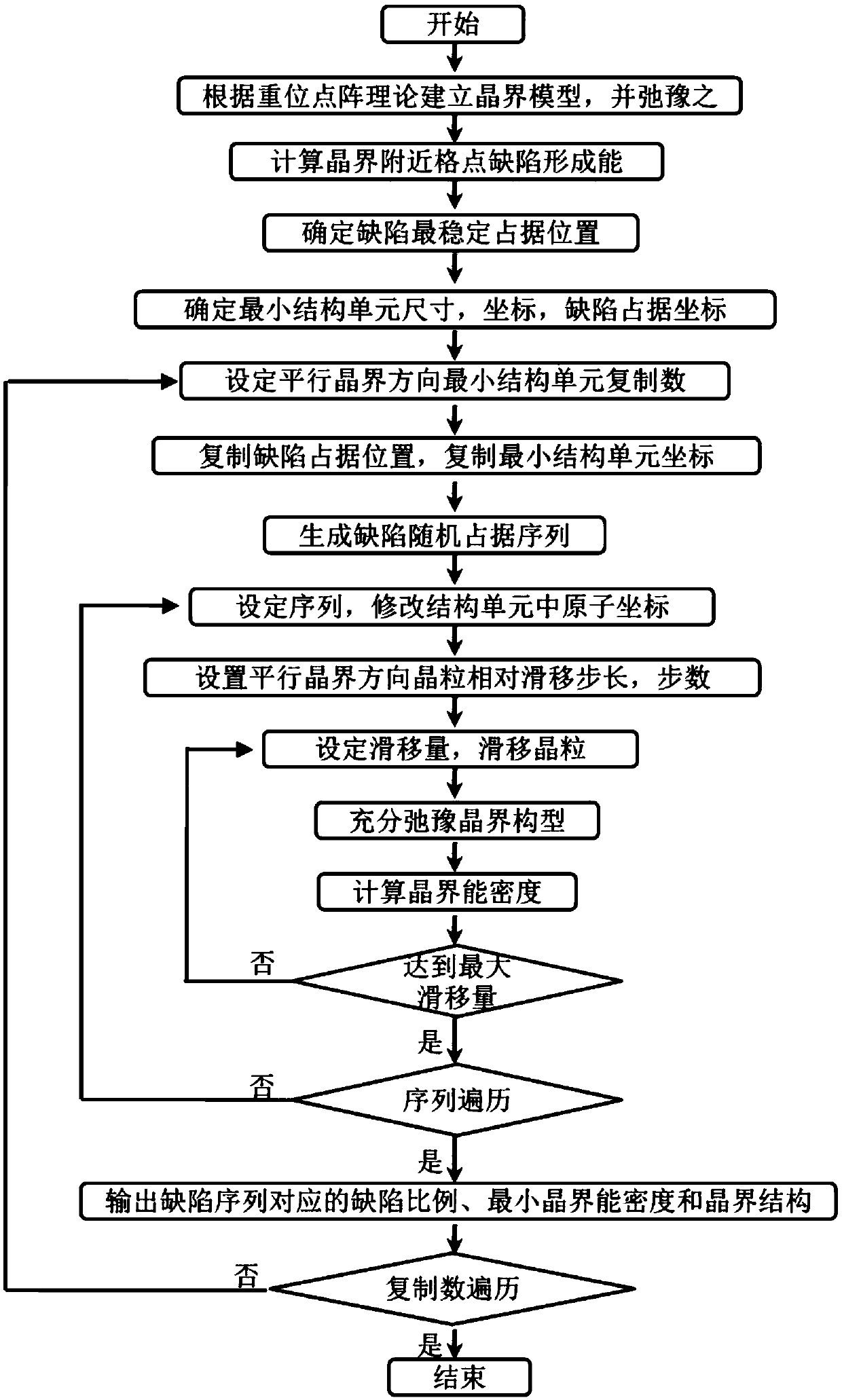

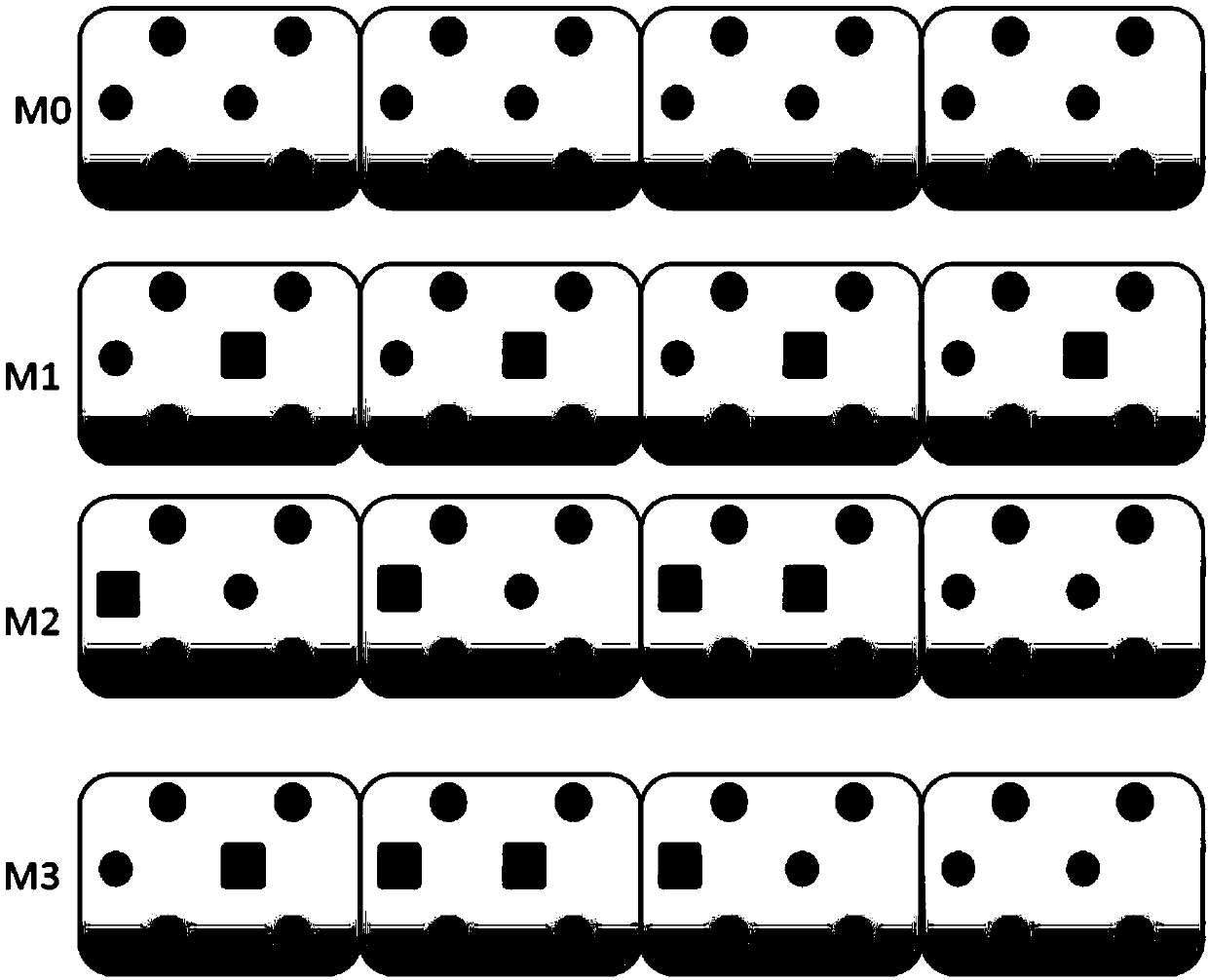

[0035] This embodiment provides a grain boundary structure search method based on defect properties and multi-scale simulation, such as figure 1 , 2 As shown in (M0-M2), when only considering the occupancy of defects, the following steps are included:

[0036] Step S1: Establish an initial grain boundary model with a certain size according to the heavy site lattice theory, and relax it. In this step, the model size of the vertical grain boundary is recommended to be 2 nanometers;

[0037] Calculate the lattice point defect formation energy in the range of 1 nanometer near the grain boundary, and the calculation method of the defect formation energy Ef is:

[0038] Ef=E 2 -E 1 ±Ecoh

[0039] Among them, E 1 and E 2 are the total energy of the perfect grain boundary and the grain boundary with defects, and Ecoh is the cohesive energy of the lattice point in the bulk;

[0040] According to the calculated lattice point defect formation energy near the grain boundary, the po...

Embodiment 2

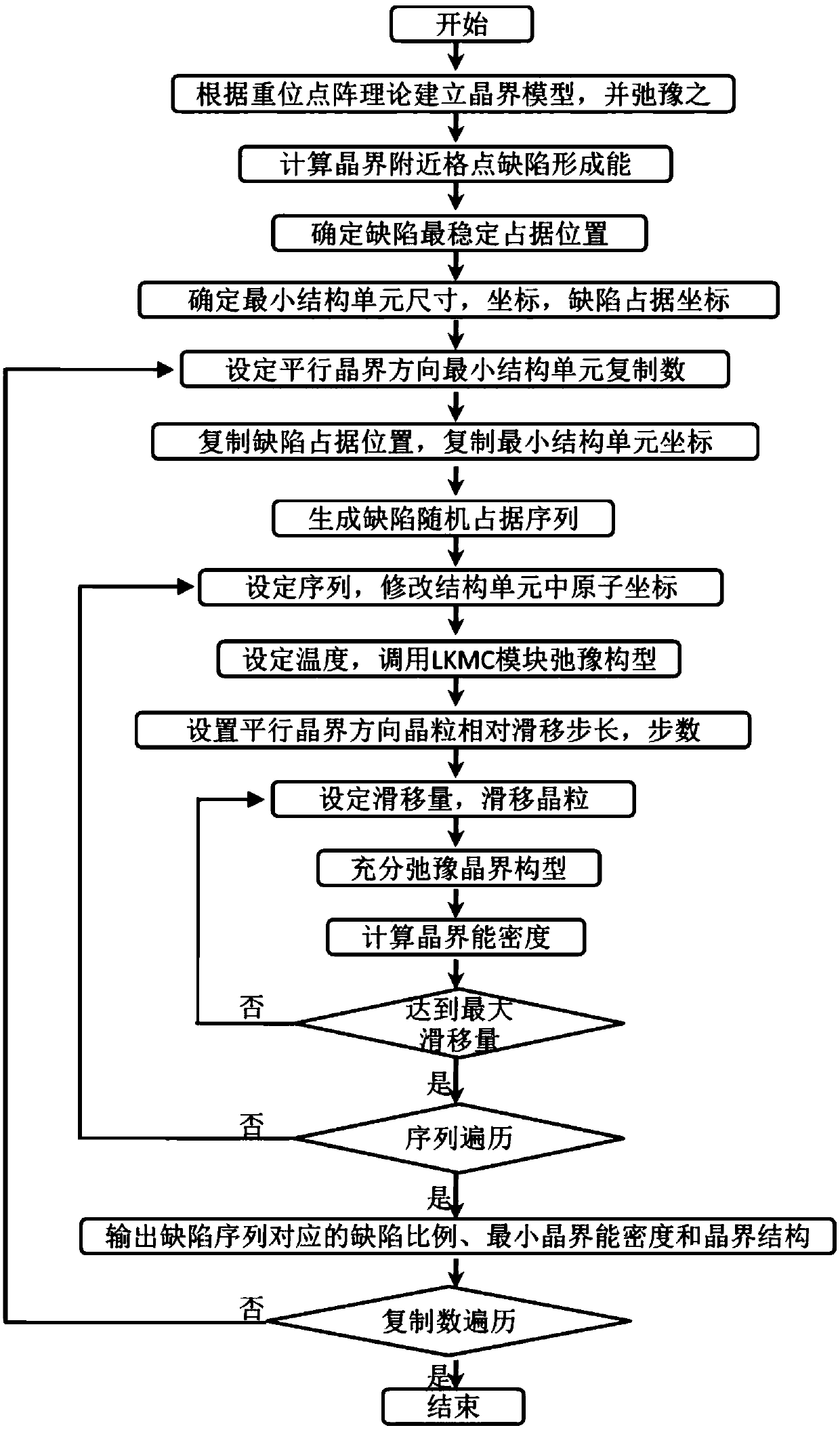

[0055] This embodiment provides a grain boundary structure search method based on defect properties and multi-scale simulation, such as figure 2 (M0-M3), as shown in 3, in the case of considering both the occupancy property of the defect and the clustering process of the defect, the following steps are included:

[0056] Step S1: Establish an initial grain boundary model with a certain size according to the heavy site lattice theory, and relax it. In this step, the model size of the vertical grain boundary is recommended to be 2 nanometers;

[0057] Calculate the lattice point defect formation energy in the range of 1 nanometer near the grain boundary, and the calculation method of the defect formation energy Ef is:

[0058] Ef=E 2 -E 1 ±Ecoh

[0059] Among them, E 1 and E 2 are the total energy of the perfect grain boundary and the grain boundary with defects, and Ecoh is the cohesive energy of the lattice point in the bulk;

[0060] According to the calculated lattice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com