Frame

A frame and frame technology, applied in prefabricated cabins, living cabins, etc., can solve problems such as low structural strength and damage, and achieve the effects of improving installation efficiency, strengthening support strength, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

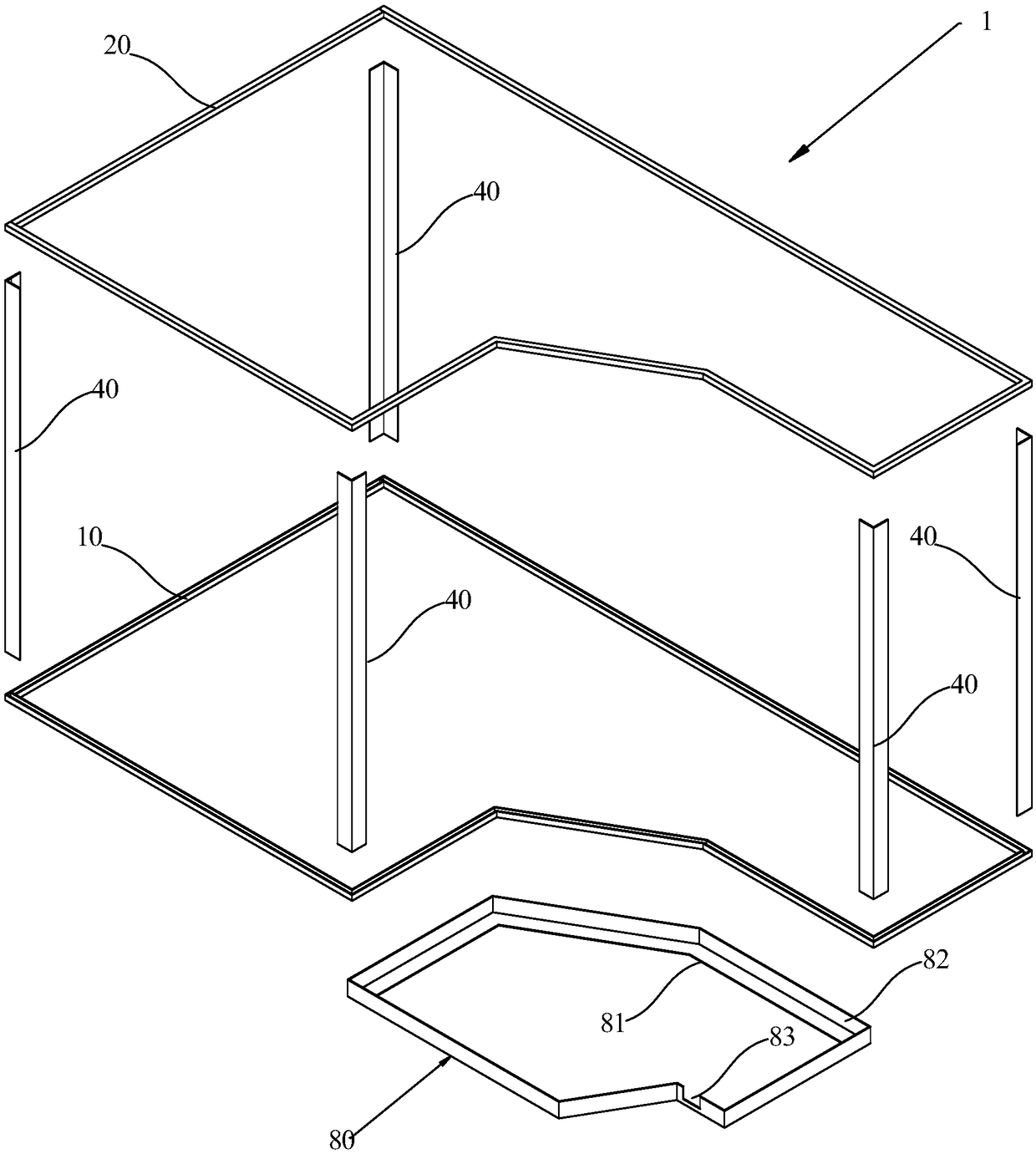

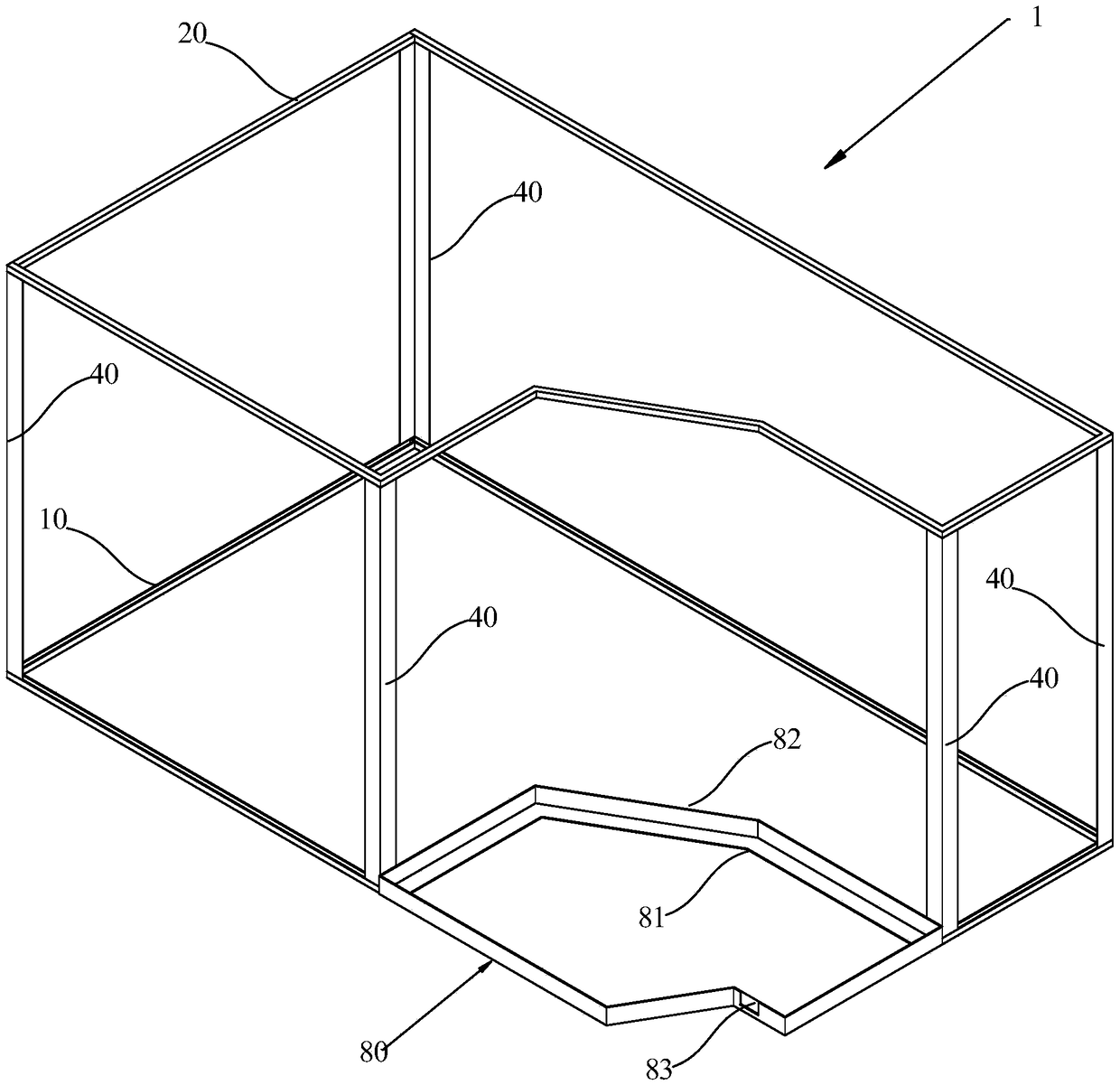

[0059] Please combine Figure 1 to Figure 6 It should be understood that this embodiment provides a frame 1 for supporting a modular unit cabin. The frame 1 comprises a bottom profile 10 , a top profile 20 and a support profile 40 .

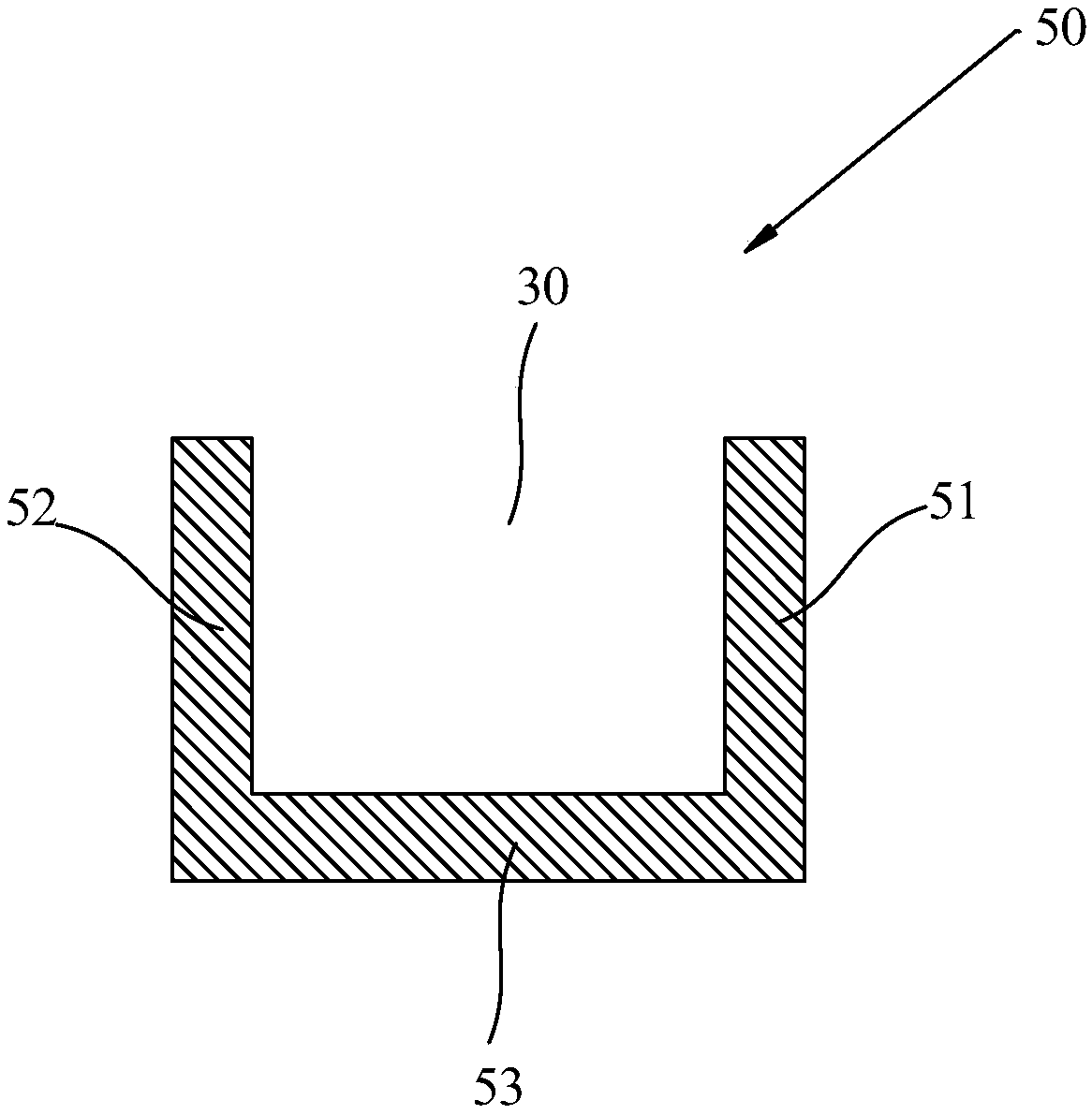

[0060] The top profile 20 is arranged opposite to the bottom profile 10 . The opposite sides of the top profile 20 and the bottom profile 10 are provided with surrounding wall board installation grooves 30 . The support profile 40 is connected between the top profile 20 and the bottom profile 10 . In this way, through the top profile 20 and the supporting profile 40 arranged opposite to the bottom profile 10, the frame 1 can be used as a three-dimensional structure, the overall structure is more stable, and the supporting strength of the modular unit cabin is greatly enhanced. Simulta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com