Mixing funnel for oil solid control

A funnel, oil technology, applied in the direction of object unsealing, containers, packaging, etc., can solve the problems of low feeding efficiency, easy diffusion of materials, affecting the health of staff, etc., to achieve the effect of increasing acceleration and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

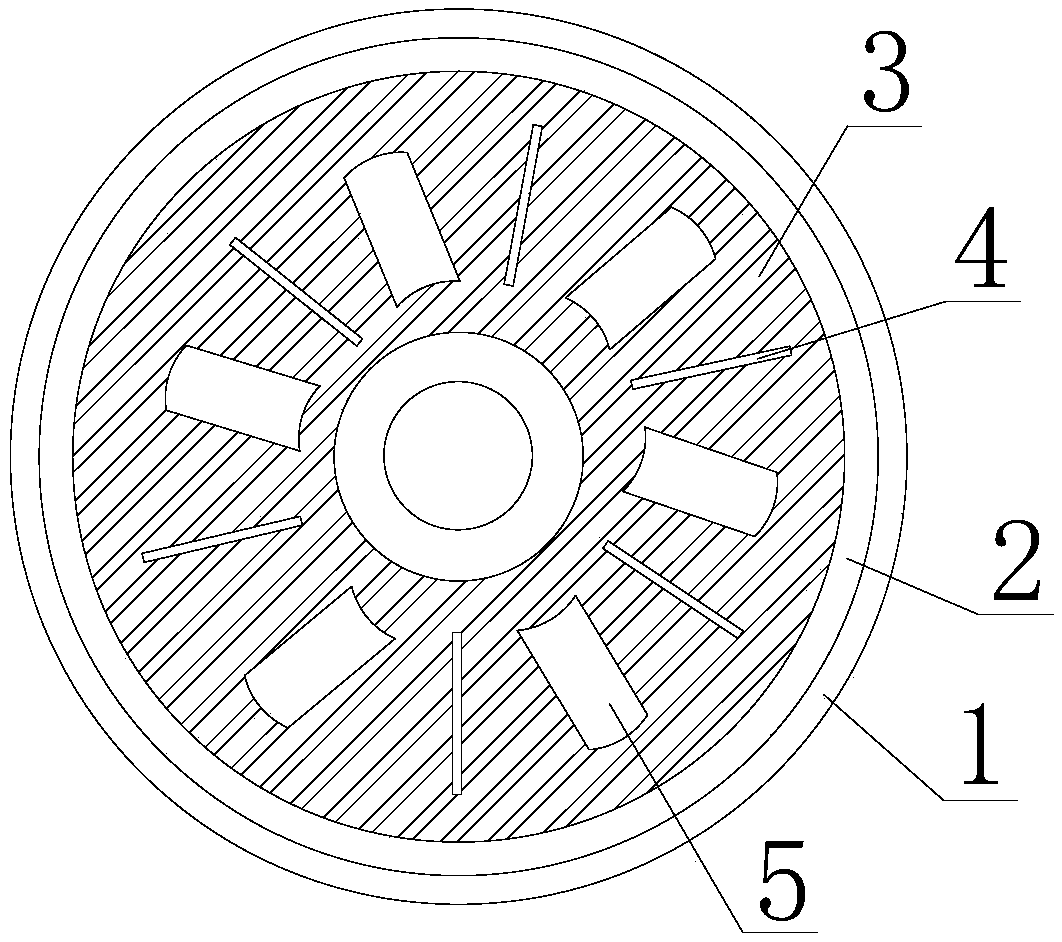

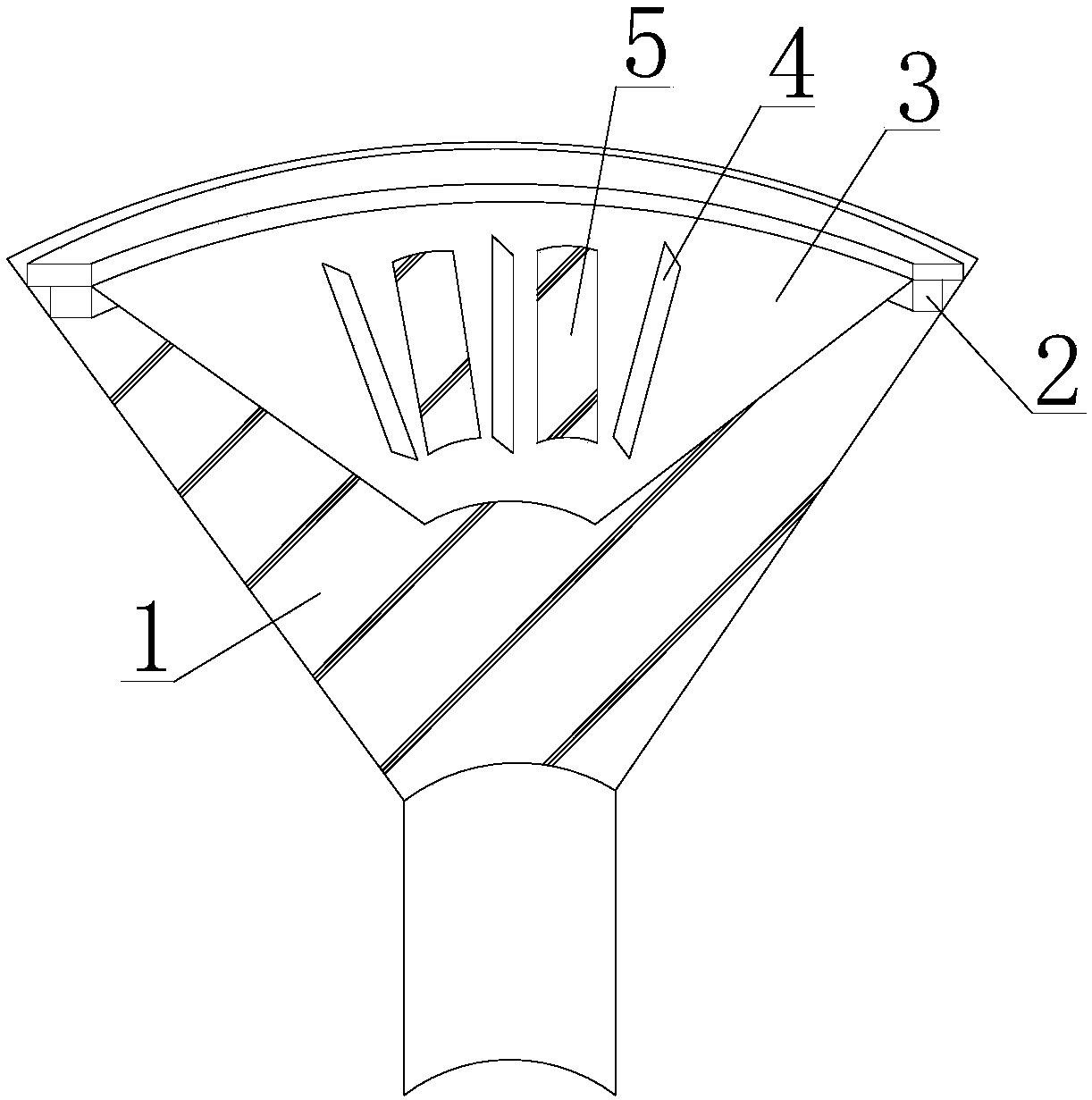

[0025] Such as figure 1 , figure 2 As shown, a mixing funnel for petroleum solids control in this embodiment includes a funnel body 1, a limiting ring 2 is arranged on the inner wall of the funnel body 1, the limiting ring 2 is welded to the inner wall of the funnel body 1, and Including a feeder, the feeder is connected to the funnel body 1 through the limit ring 2, the hopper 3 is screwed to the limit ring 2, and the feeder includes a trumpet-shaped hopper 3, a cutter 4. The opening hopper 3 is connected to the funnel body 1 through the limit ring 2, the inner diameter of the opening hopper 3 gradually decreases from top to bottom, and the cutting knife 4 is arranged on the inner wall of the opening hopper 3, and the cutting knife 4 is welded with the inner wall of opening hopper 3.

[0026] When working: the opening hopper is connected to the funnel body through the limit ring, the connection method can be fixed connection, the fixed connection can be welded, or it can b...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 , figure 2 As shown, the limiting ring 2 is a circular ring, and the axis of the limiting ring 2 is parallel to the axis of the funnel body 1 . The purpose of setting the limit ring as a circular ring is to ensure that the inner wall of the funnel body is in contact with the limit ring, so that the funnel body can support the limit ring more effectively; The contact surface is used to support the opening hopper, so that the connection between the opening hopper and the funnel body is stable.

Embodiment 3

[0030] On the basis of Example 1, such as figure 1 As shown, the cutter 4 is rectangular, and the back of the cutter 4 is parallel to the inner wall of the hopper 3 . Avoid the materials blocked by the cutter from falling into the funnel body from the open hopper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com