LED lamp lead wire frame strip electroplating guide frame

A technology of guide frame and lamp lead wire, which is applied in the direction of electrolysis process, electrolysis assembly, contact device, etc., can solve the problems of wear and deformation of LED lamp lead frame belt, and difficulty in adjusting the distance between two brass blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

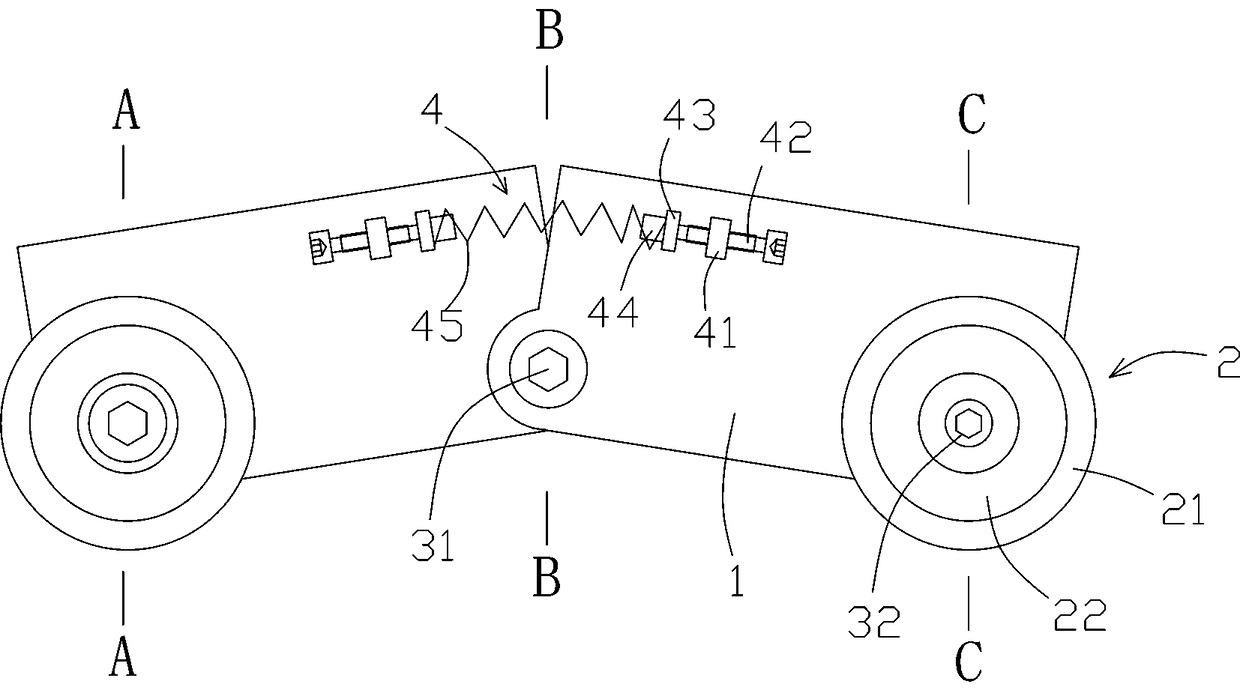

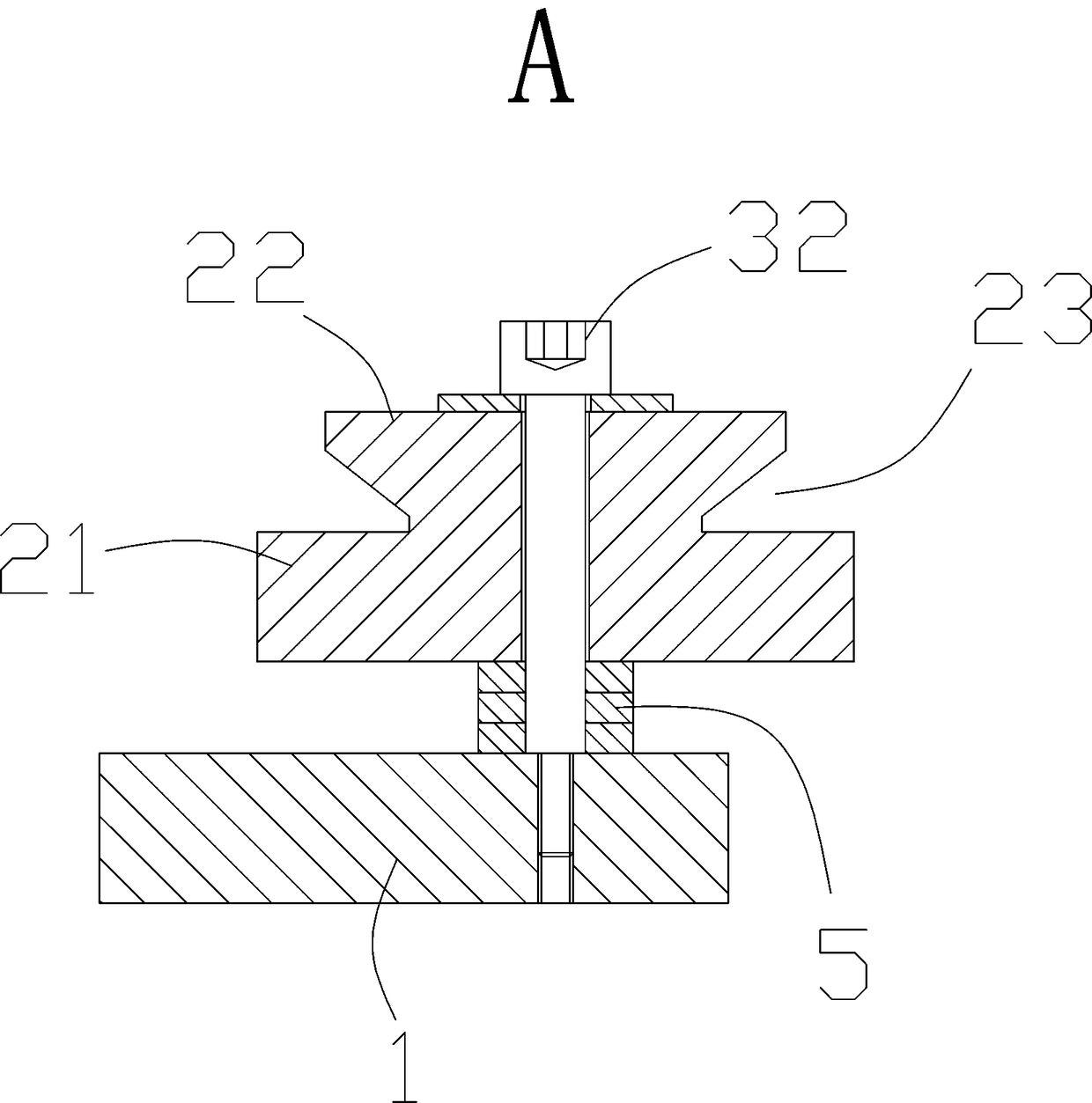

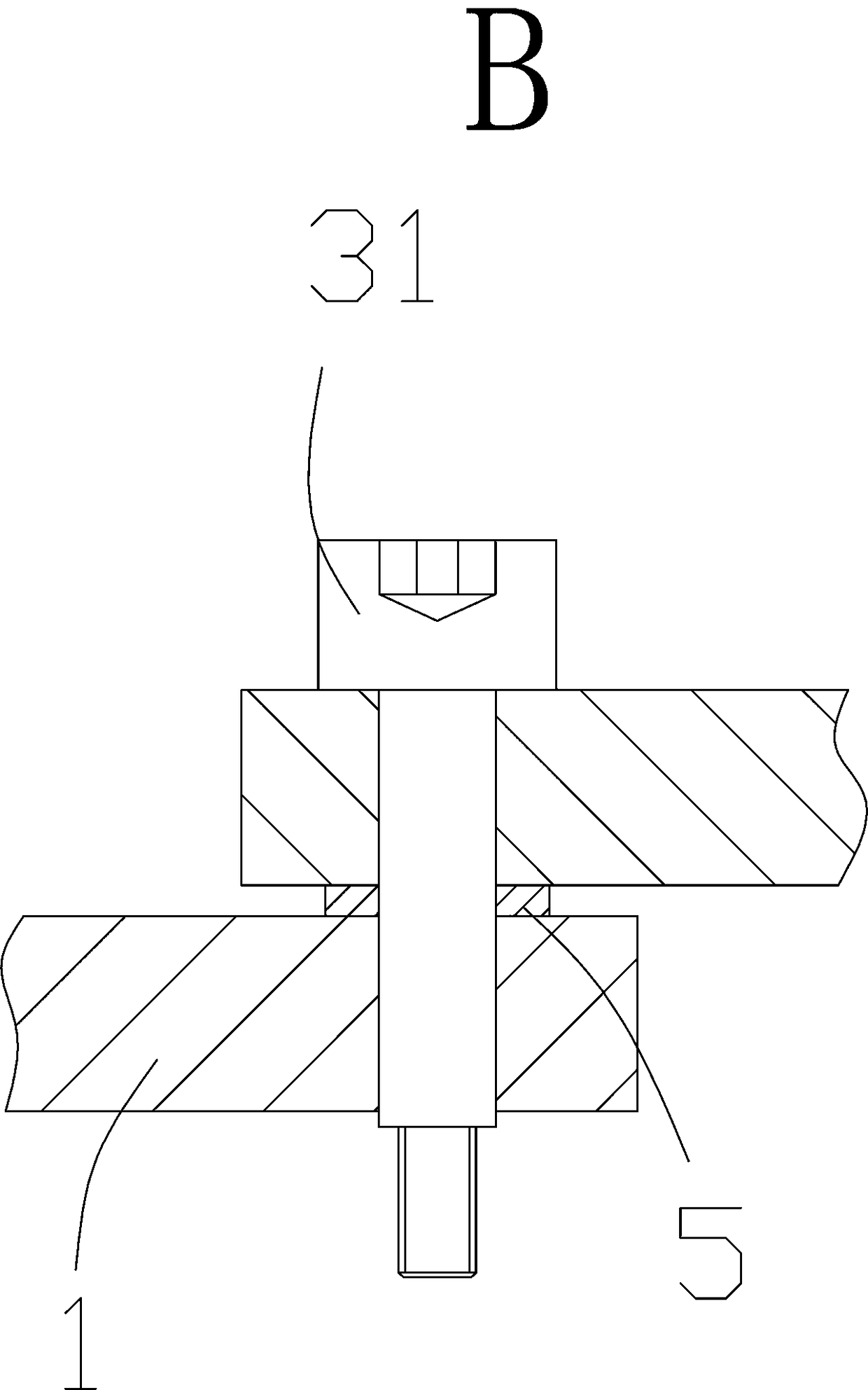

[0014] Such as Figure 1 to 5 As shown, an LED lamp lead frame with electroplating guide frame includes two sets of guide frames arranged oppositely in the electroplating tank (not shown in the figure of the electroplating tank), and the LED lamp lead frame tape 5 is clamped between the two sets of guide frames. The guide frame includes two supporting plates 1 whose corners are connected together by a first bolt shaft 31. The first bolt shaft 31 is screwed in the electroplating tank. The two supporting plates 1 are away from one end of the first bolt shaft 31. Connected by an elastic mechanism 4, the elastic mechanism 4 can push the two supporting plates 1 to rotate inward around the first bolt shaft 31, and a guide mechanism is installed on each supporting plate 1, and the guide mechanism includes a threaded connection The second bolt shaft 32 on the support plate 1, and the guide wheel 2 mounted on the second bolt shaft 32, the guide wheel 2 is composed of a cylindrical lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com