Electroplating roller

A technology of electroplating rollers and cylinder walls, applied in the electrolysis process and electrolysis components, etc., can solve the problems of easy falling off, uneven electroplating of parts, weak installation of doors, etc., and achieves the effect of firm connection and convenient disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

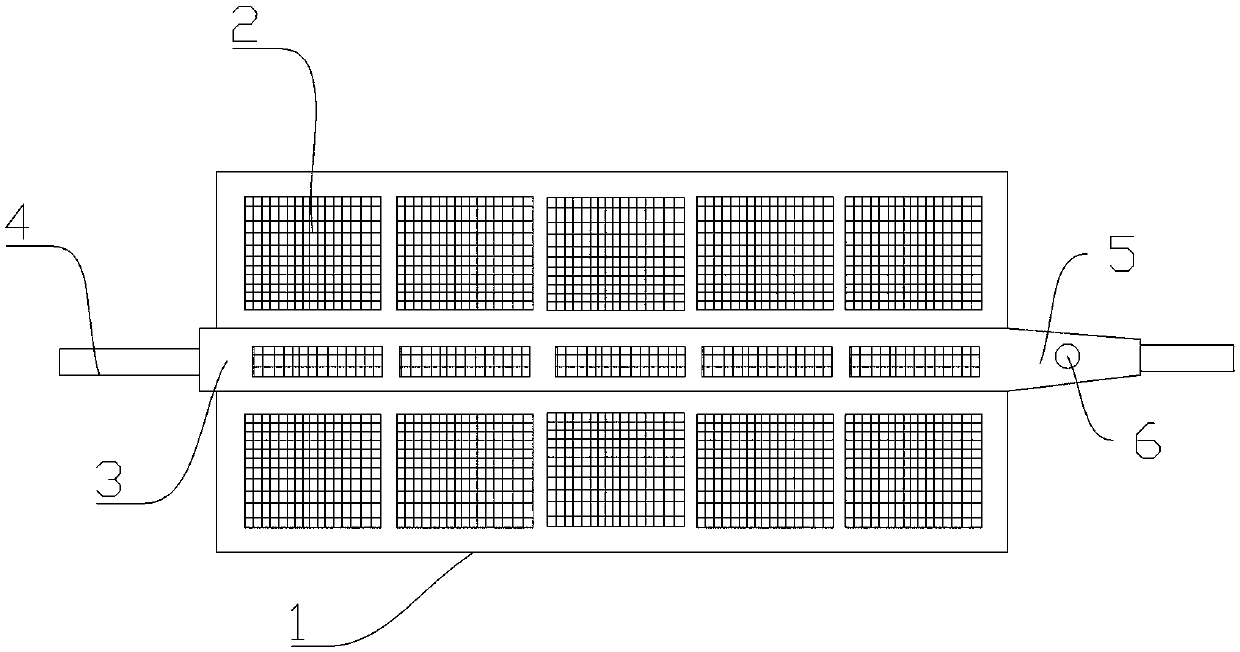

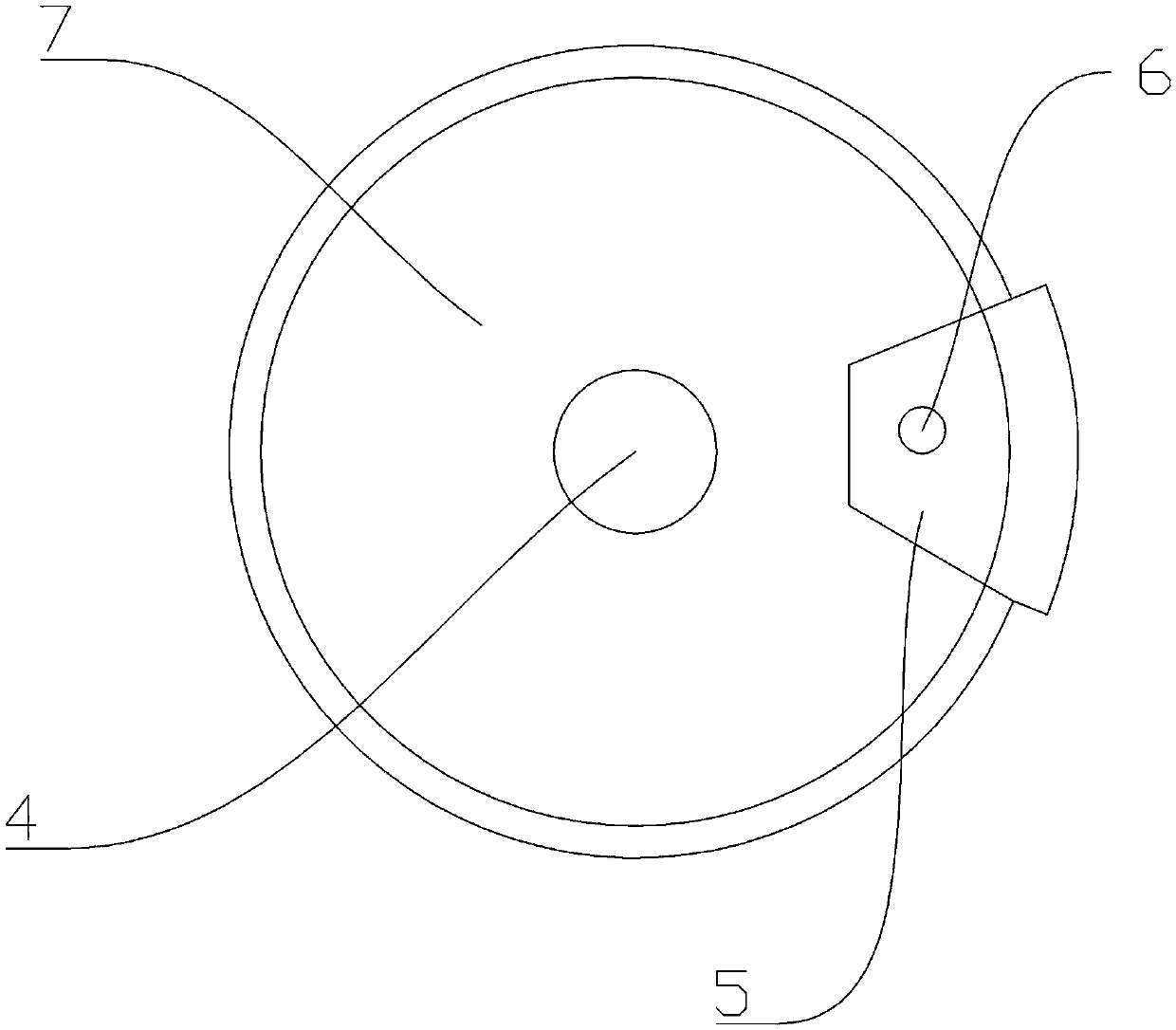

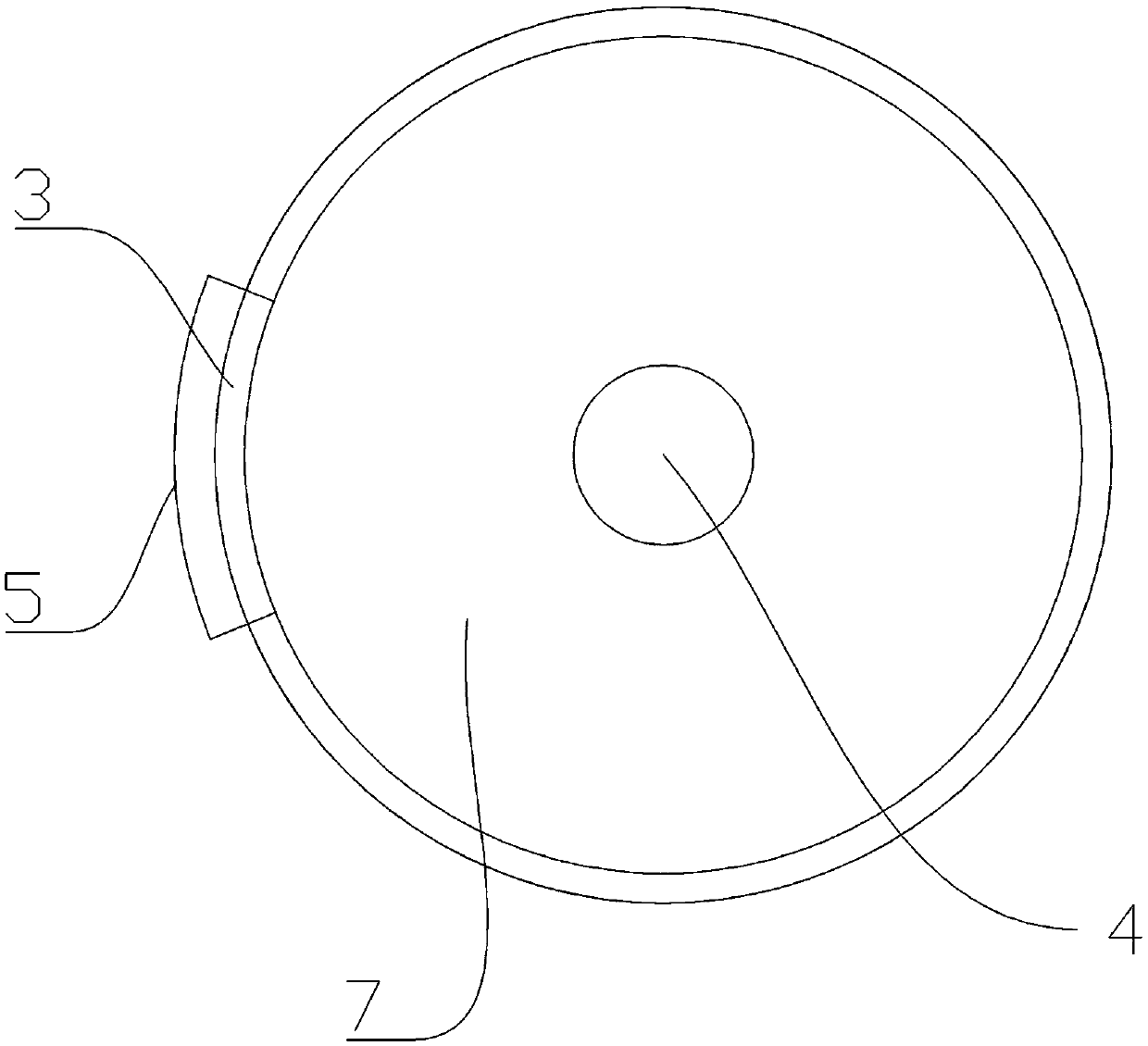

[0016] The reference signs in the drawings of the specification include: cylinder wall 1 , mesh 2 , door 3 , rotating shaft 4 , fastening plate 5 , connection hole 6 , and side plate 7 .

[0017] The embodiment is basically as attached figure 1 , figure 2 , image 3 As shown: Mesh holes 2 are evenly distributed on the cylinder wall 1, and side plates 7 are installed at both ends of the cylinder wall 1. In the gap; the center of the side plate 7 is installed with a rotating shaft 4 that drives the roller to rotate; the inner wall of the side plate 7 is also provided with evenly distributed protrusions. There is an opening on the cylinder wall 1, the opening is rectangular, the two ends of the opening are respectively two side plates 7, the opening is provided with a door 3, the door 3 is provided with a mesh 2, the door 3 is arc-shaped, the door 3 and the The openings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com