Bevel gear and manufacturing method and mold thereof

A technology of bevel gears and molds, which is applied to belts/chains/gears, textiles and papermaking, and components with teeth, etc. It can solve the problems of bevel gears with high noise and fast wear, and achieve high yield, reduce energy consumption, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

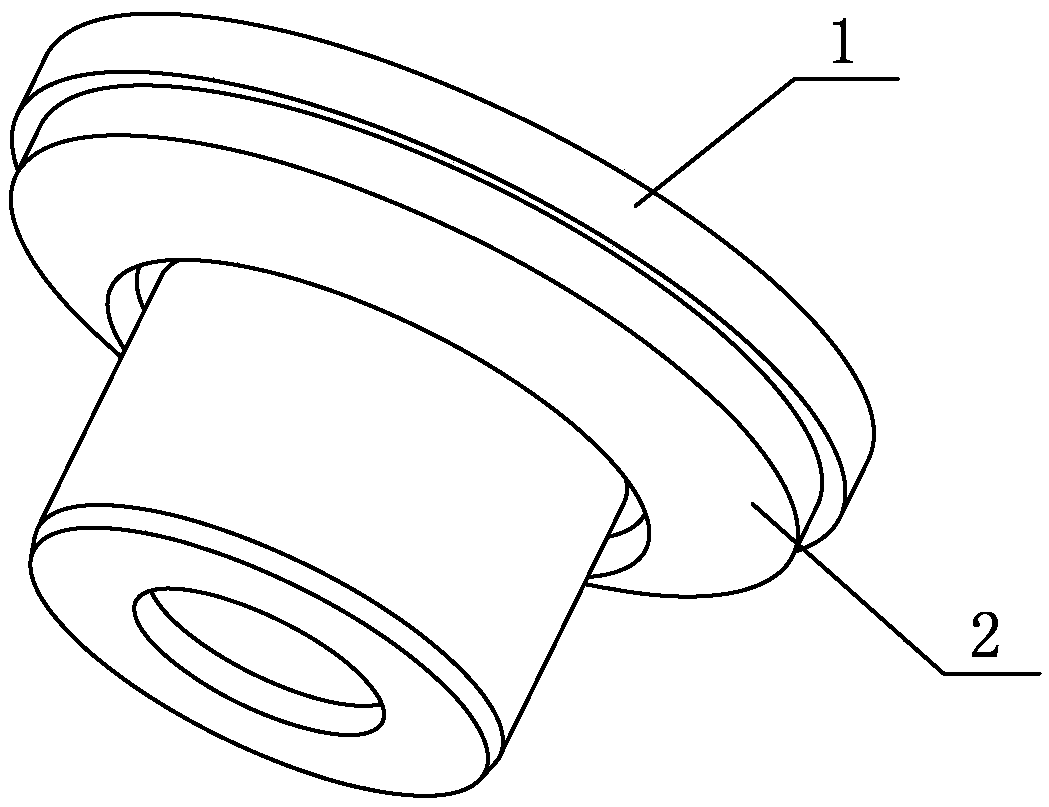

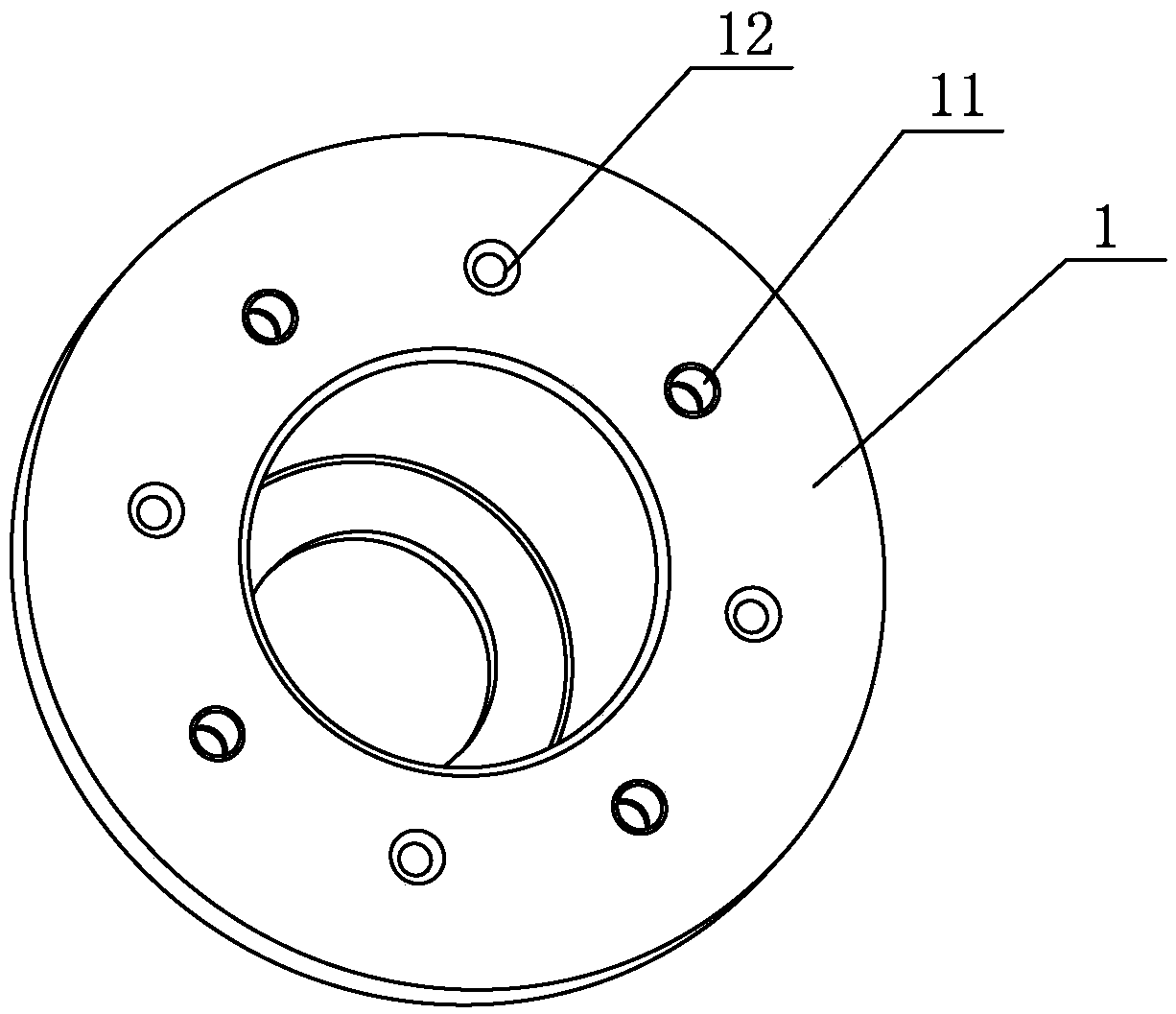

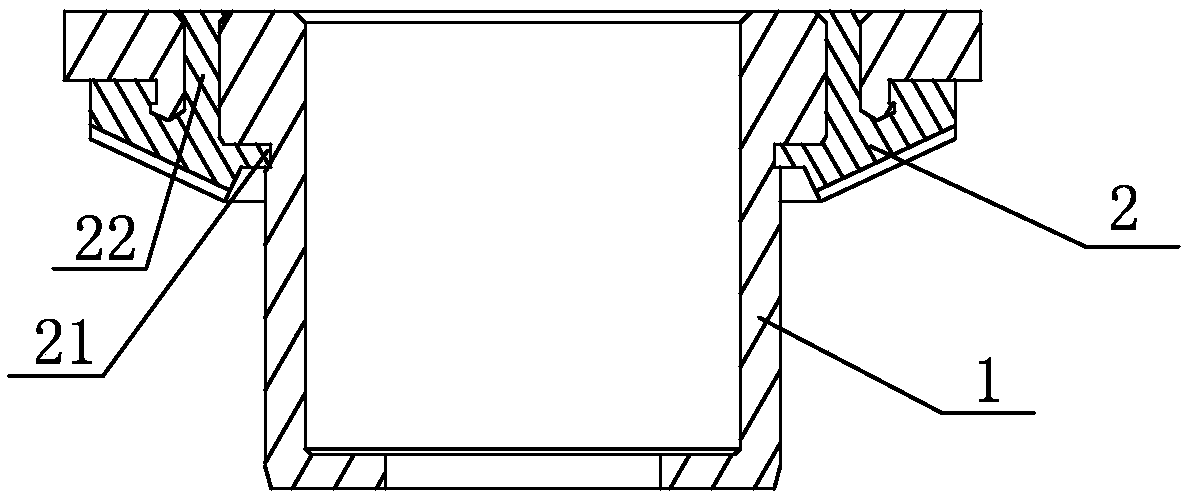

[0026] Such as Figure 1 ~ Figure 4 Shown is the first bevel gear embodiment of the present invention, Figure 5 ~ Figure 6 Shown is a second bevel gear embodiment of the present invention. The bevel gears of both embodiments include a metal skeleton 1 and a PEEK plastic ring gear 2 injection-molded on the skeleton. The skeleton includes a hub 14 and a web 13. The hub 14 and the web 13 are integrated, and the web is arranged along the circumferential direction. There are a plurality of limiting through holes 12, the top opening of the limiting through hole 12 is a trumpet-shaped opening with a large mouth facing upward, the ring gear 2 includes a wheel rim and gear teeth formed on the wheel rim, and the wheel rim is attached to the web 13 A convex post 22 extending into the limit through hole 12 is formed on the wheel rim. The top of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com