Multifunctional weaving machine

A multi-functional loom technology, applied in dryers, progressive dryers, drying solid materials, etc., can solve the problem of unsatisfactory drying effect and achieve simple structure, convenient operation and smooth operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

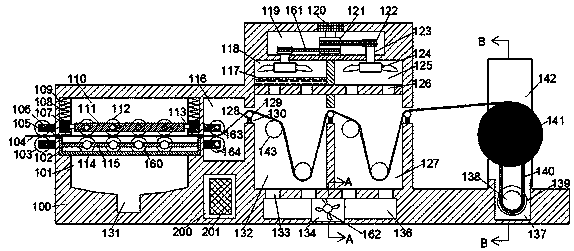

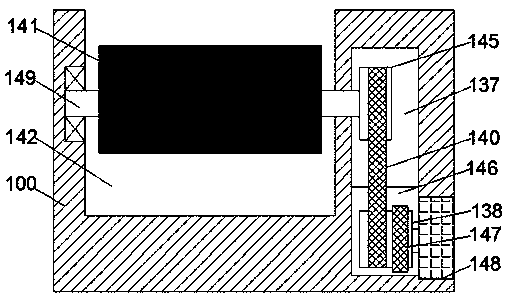

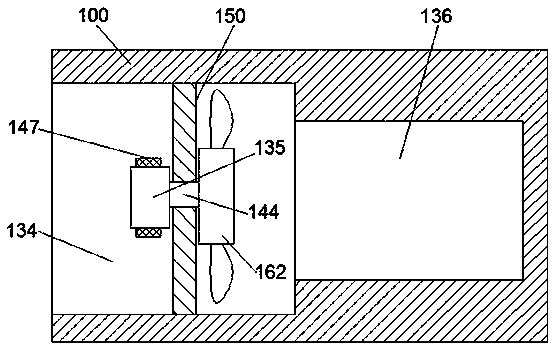

[0016] Such as Figure 1-3 As shown, the multifunctional loom of the present invention includes a body 100 and a dehydration chamber 110 disposed in the body 100 with an opening downward. The lower end of the dehydration chamber 110 communicates with a water collection chamber 101 with an upward opening. The right end of the chamber 110 is provided with a transition chamber 116 with an opening forward, the right end of the transition chamber 116 is provided with a first drying chamber 132, the right end of the first drying chamber 132 is provided with a second drying chamber 127, and the first drying chamber 132 is provided with a second drying chamber 127. The top of the drying chamber 132 is provided with a hot air chamber 118, the top of the second drying chamber 127 is provided with a cold air chamber 125, and the top of the cold air chamber 125 and the top of the hot air chamber 118 are provided with a first pulley chamber 119. A drying chamber 132 and the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com