Method for on-line monitoring running state of hot rolling edging mill

A technology of vertical rolling mill and running state, which is applied in the testing of machine/structural components, vibration measurement in solids, measurement of vibration, etc. problem, to avoid unplanned downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

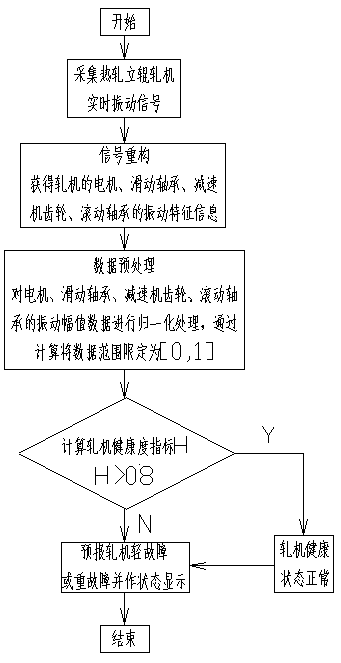

[0029] Example figure 1 As shown, the on-line monitoring method of the hot rolling vertical rolling mill operating state of the present invention, the hot rolling vertical rolling mill is driven by a motor and a speed reducer, and the motor and the speed reducer include sliding bearings and rolling bearings. The method includes the following steps:

[0030] Step 1. Install vibration sensors on the sliding bearing housing and rolling bearing housing, and collect the original signal Y output by the vibration sensor i , for the original signal Y i Perform frequency spectrum analysis and obtain characteristic information of motor, sliding bearing, reducer gear and rolling bearing through signal reconstruction, and extract motor vibration amplitude Mi, sliding bearing vibration amplitude Ji, reducer gear vibration amplitude Gi and rolling bearing vibration amplitude Ri;

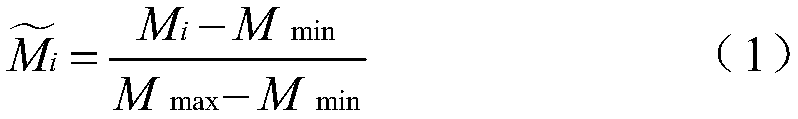

[0031] Step 2, data preprocessing, normalize the motor vibration amplitude Mi data, and limit the range of da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com