A gear reliability analysis method

An analysis method and reliable technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low, large calculation, error-prone precision, etc., to simplify the calculation process and reduce the calculation Small, the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, and the following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0056] Aiming at the problems in the prior art that the gear reliability analysis methods are too large in calculation, error-prone and low in precision, a gear reliability analysis method is proposed:

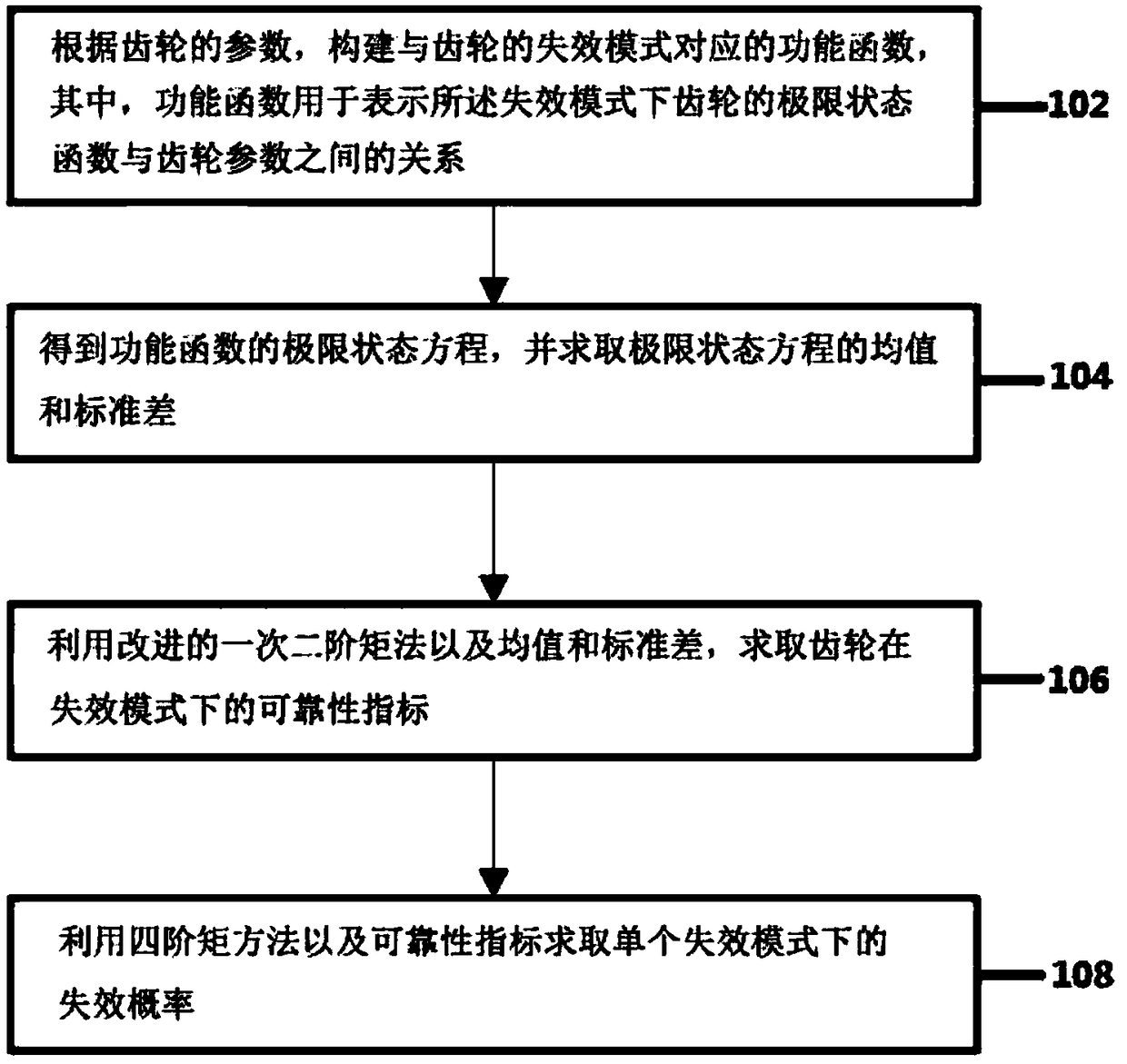

[0057] combine figure 1 , the steps mainly include:

[0058] Step 102: Construct a function function corresponding to the failure mode of the gear according to the parameters of the gear, wherein the function function is used to represent the relationship between the limit state function of the gear and the gear parameters in the failure mode;

[0059] Step 104: Obtain the limit state equation of the functional function, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com