Brushless DC motor lead wire needle guard seat structure and brushless DC motor thereof

A brushless DC motor, lead pin technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of installation method error, lead pin bending, affecting production, etc., to ensure the effect of normal wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

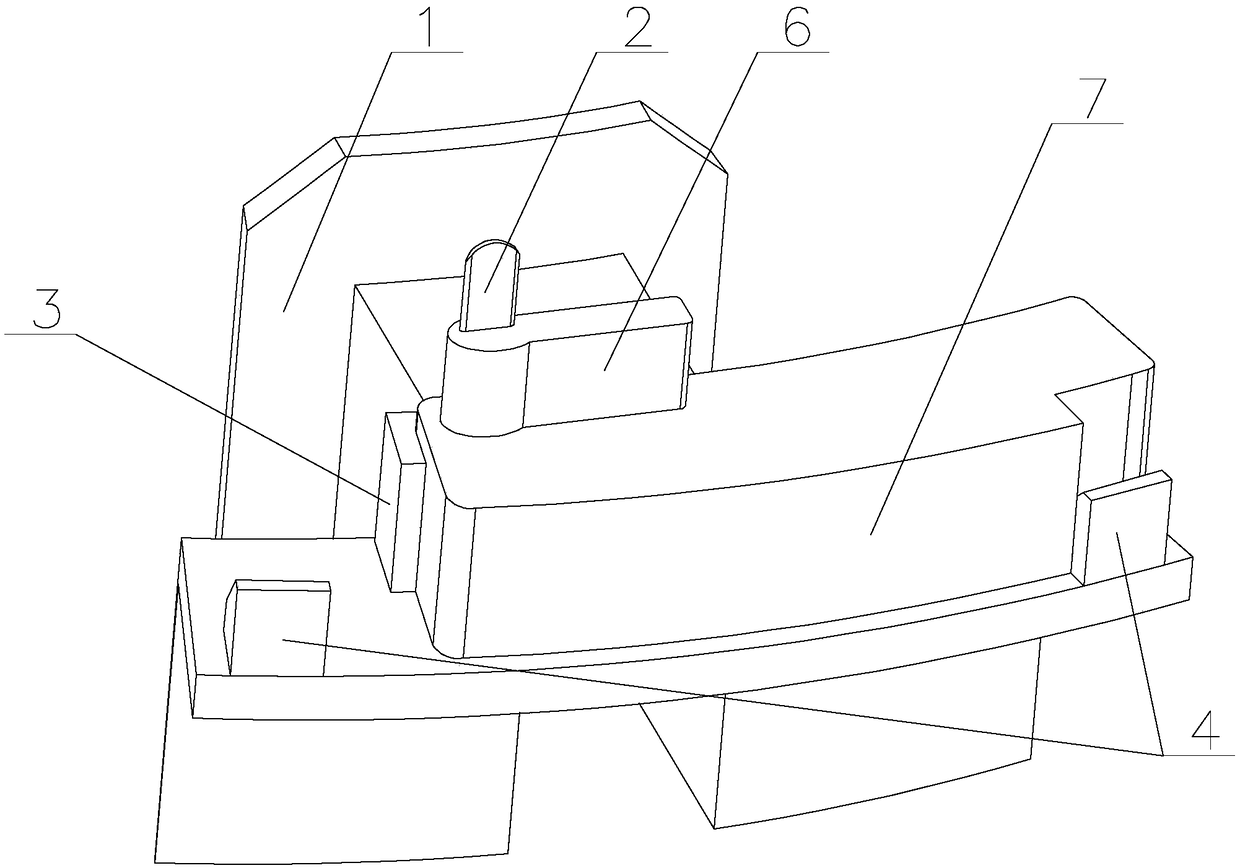

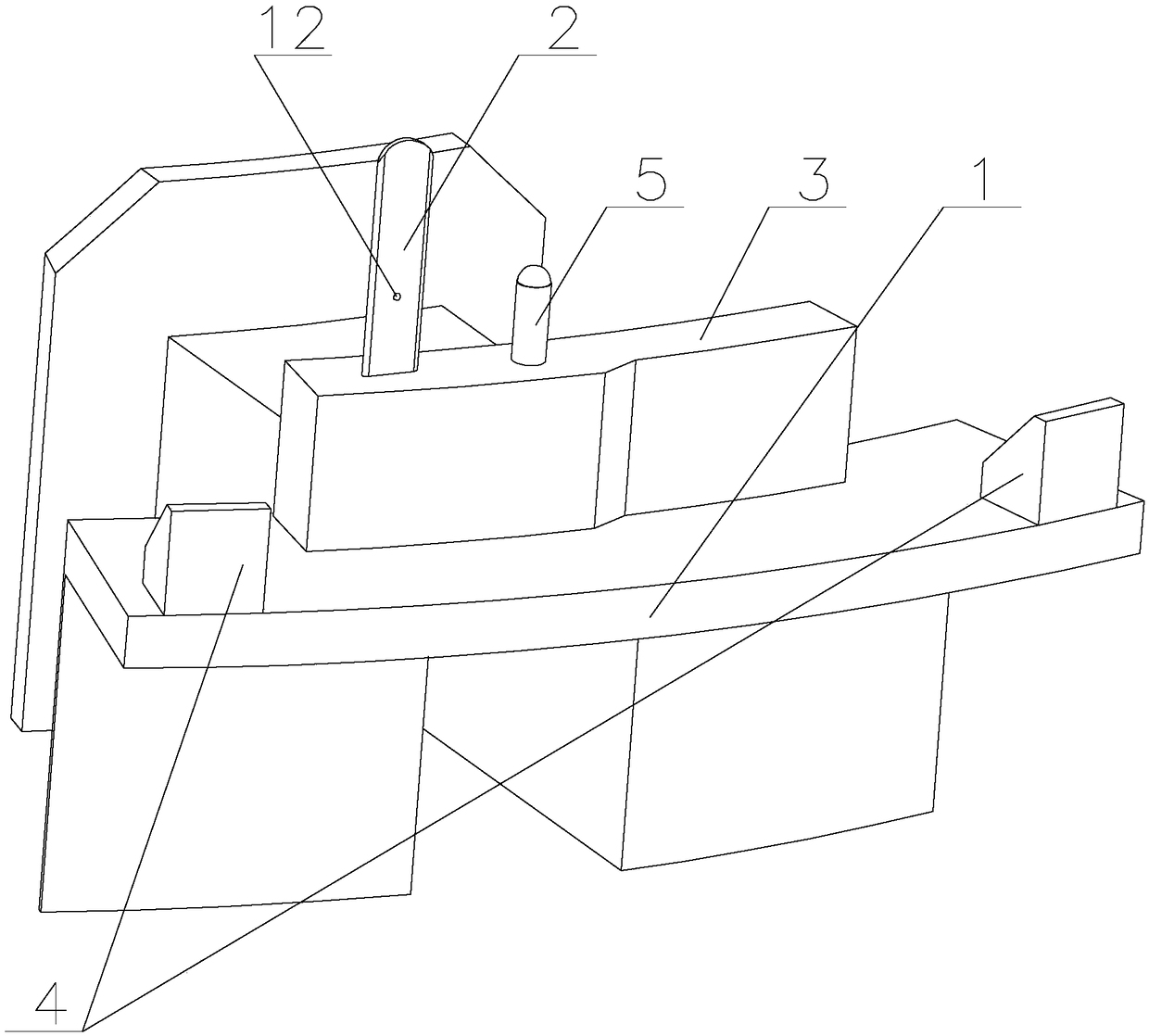

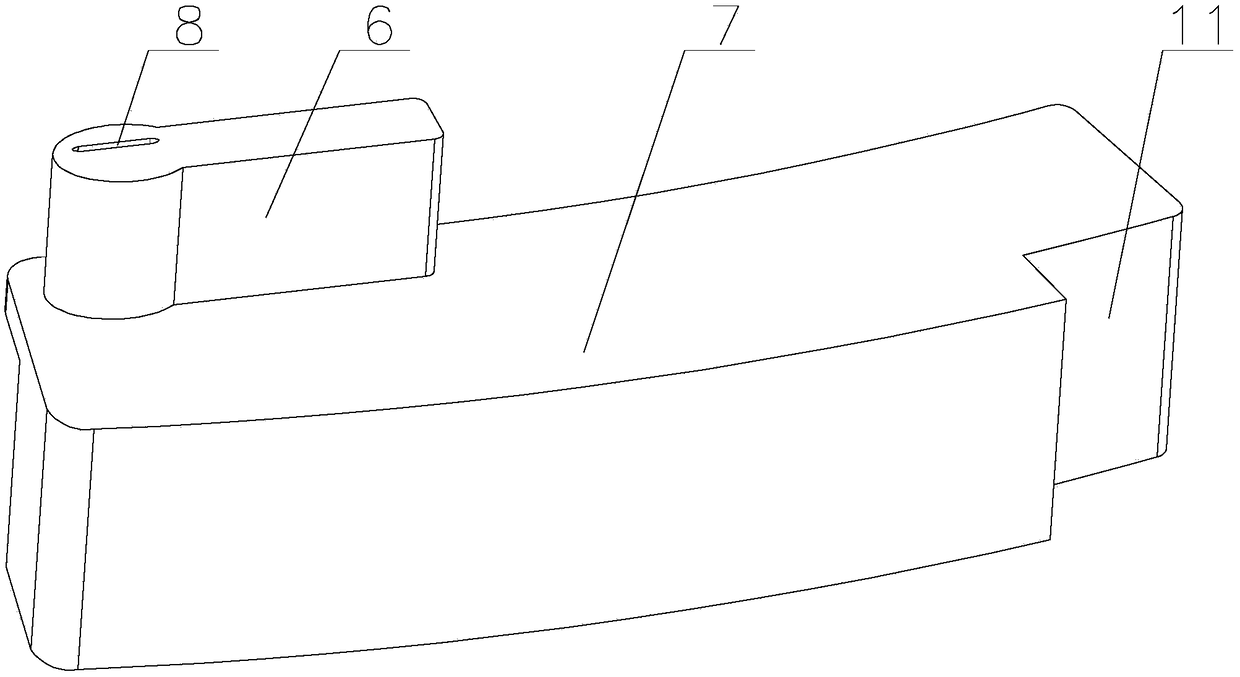

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0023] Such as Figure 1-5 As shown, a DC brushless motor wire needle guard seat structure of the present invention includes a skeleton 1, and the skeleton 1 is provided with a wire needle 2, a needle guard, a connecting block 3 and two correction blocks 4, the The upper end of the connection block 3 is provided with a pin hole, and one side of the pin hole is vertically provided with a limit column 5, and the limit column 5 is integrally processed with the connection block 3, and the correction block 4 is arranged on the Outside the connection block 3, a limit groove for limiting the position of the needle guard is provided between the correction block 4 and the connection blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com