Leeks precision sowing, fertilization, and weeding all-in-one machine

A precision seeding and all-in-one machine technology, applied in weed eradication equipment, agricultural machinery and implements, shovels, etc., can solve problems such as single function, uneven distribution of onion seeds, and restrictions on the development of the onion industry, and achieve low labor intensity , high seeding efficiency, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

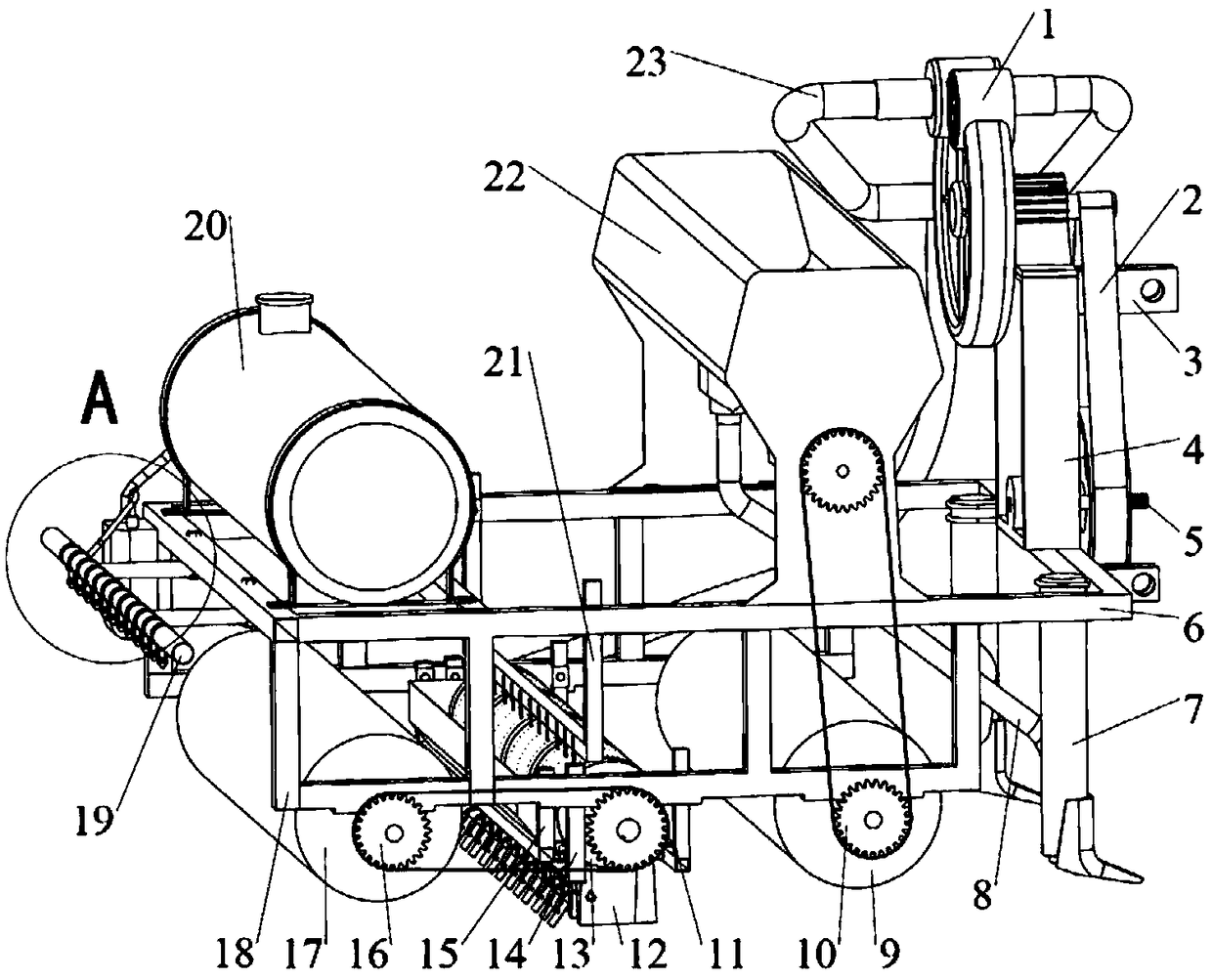

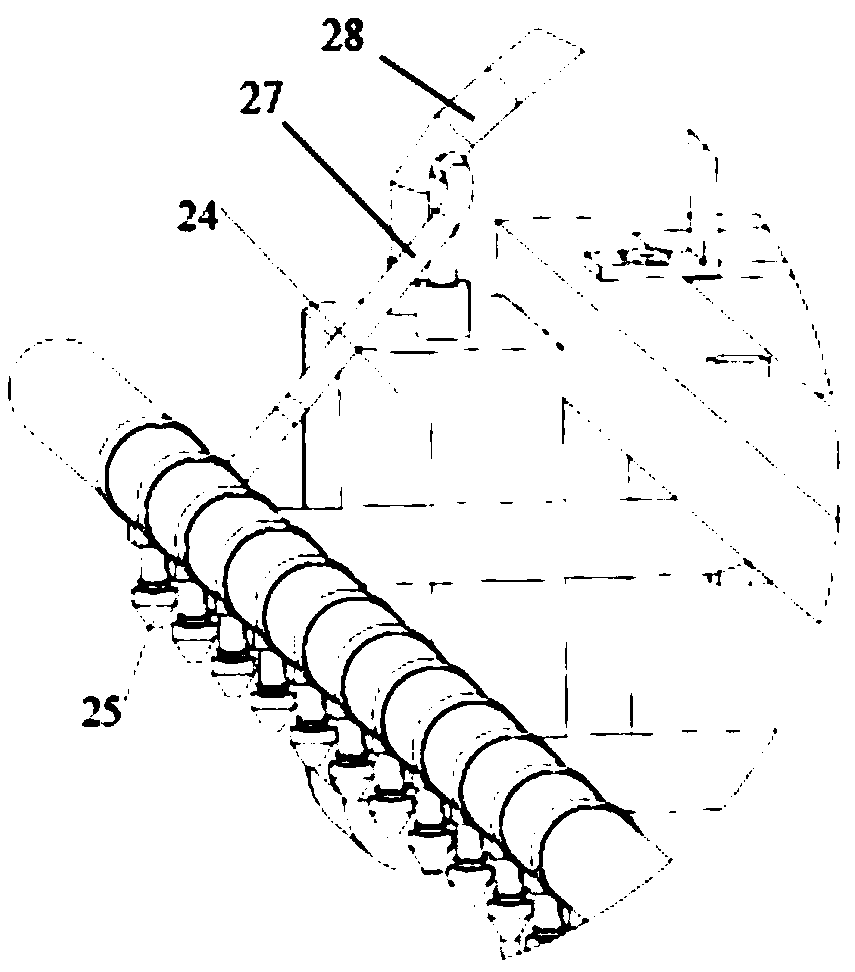

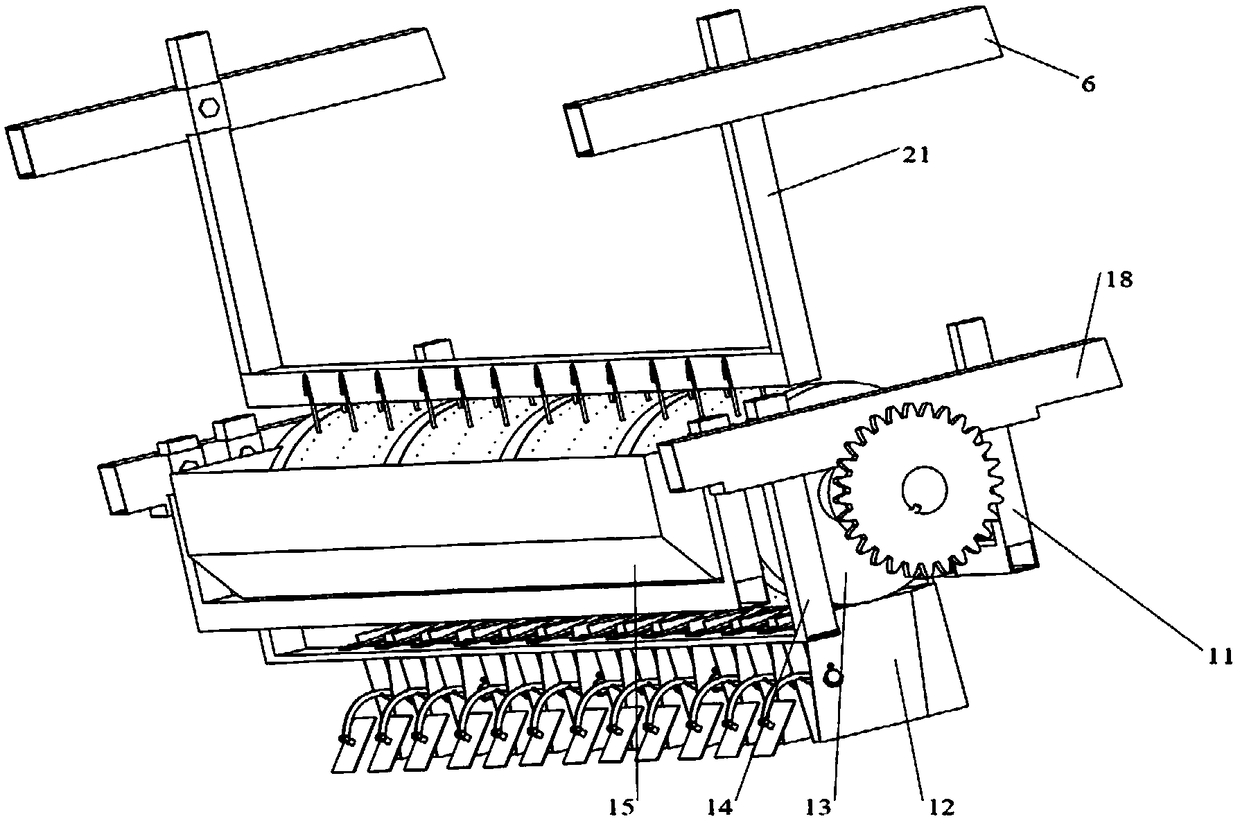

[0032] like figure 1 , figure 2 As shown, the integrated equipment for precision sowing, fertilizing and weeding of scallions includes mainly three-point suspension device 3, frame, soil preparation roller 9, fertilization device, air suction seeding device, pressing roller 17 and herbicide spraying device. composition. The air suction sowing device includes a fan 1 , a belt drive 2 , a fan mounting frame 4 , a conduit 23 , an air suction drum type metering device 13 and a ditching soil covering device 12 . The fan 1 is installed above the fan mounting frame 4, the front side of the fan mounting frame 4 is a belt drive 2, the driven wheel of the belt drive is connected with the fan, and the driving wheel is connected with the tractor power output shaft through the spline shaft 5.

[0033]The fertilization device include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com