Tea brick preparation method

A preparation process and technology of tea bricks, which are applied in the direction of tea treatment before extraction, etc., can solve the problems of unfavorable long-term storage of tea bricks, mildew of tea bricks, etc., and achieve the effects of improving compactness, storage time and pressing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

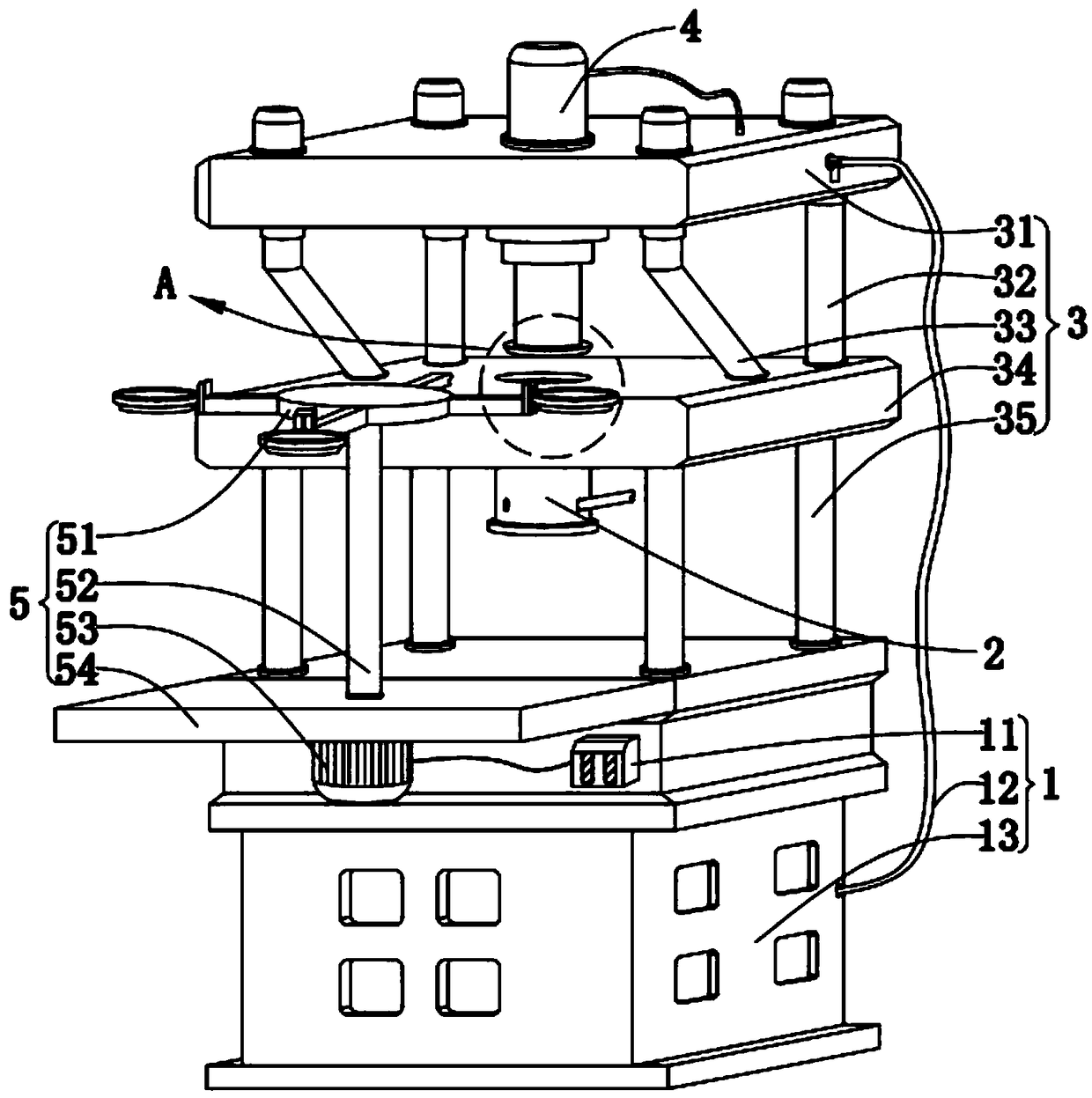

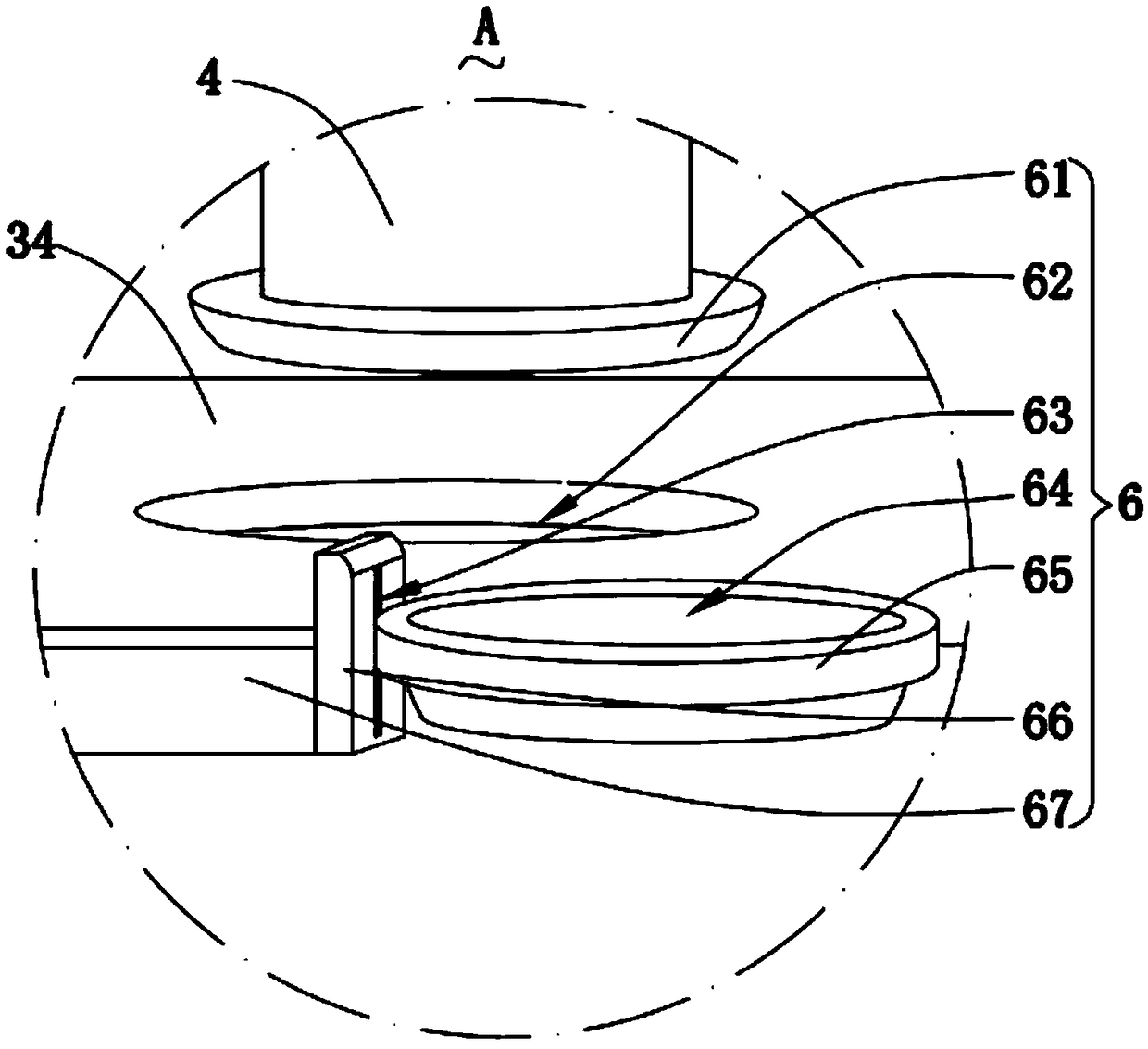

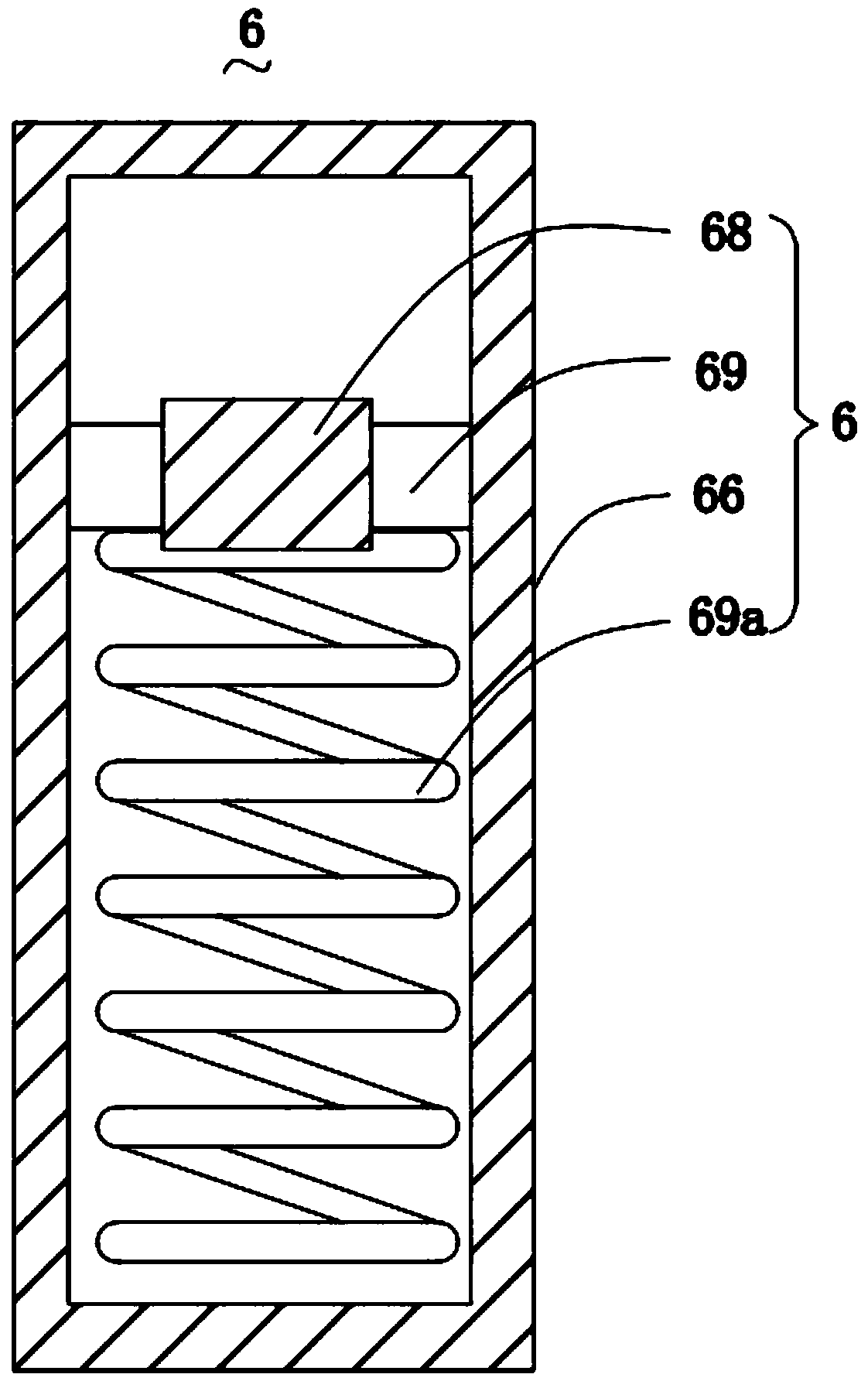

[0026] like figure 1 , figure 2 and Figure 4 Shown, a kind of tea brick preparation process of the present invention, this process comprises the following steps:

[0027]S1, put the fried tealeaves in a cool place to dry, rub the tealeaves with hands, and it is advisable not to squeeze out the water;

[0028] S2, put the dried tea leaves in S1 into a tea press machine for pressing, while pressing, feed high-temperature water vapor into the pressing chamber, the high-temperature water vapor can increase the humidity of the tea leaves, and facilitate the pressing and molding of the tea leaves. At the same time, high-temperature steam is also beneficial to sterilize the tea leaves; high-temperature water steam uses water vapor above 100 degrees ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com