Chinese chestnut frying device

A chestnut and stir-frying technology, which is applied in the application, food processing, food science and other directions, can solve the problems of uneven heating, inability to stir-fry chestnuts, and complicate the process of collecting chestnuts, and achieve the effect of improving the uniformity of heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now do further detailed explanation in conjunction with accompanying drawing.

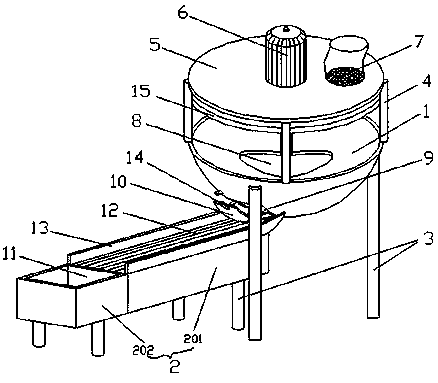

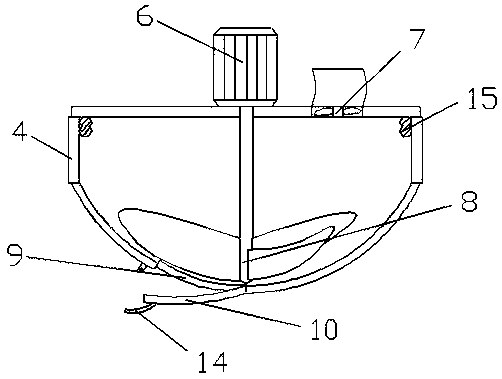

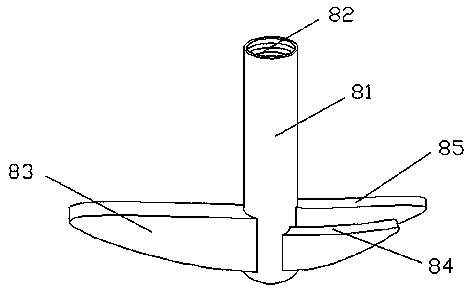

[0018] Such as Figure 1-4 As shown, a chestnut frying device includes a pot body 1 and a receiving box 2, the pot body 1 is a hemispherical structure, the pot body and the receiving box are supported by support legs 3, and the edge of the pot mouth is provided with supports Rod 4, the top of support rod 4 is provided with cover plate 5, is provided with motor 6 and hood 7 on cover plate 5, and motor 6 is positioned at the center of cover plate 5, and its motor shaft is equipped with stirring stir-fry member 8, and described pot body There is a discharge port 9 extending from the center of the pot bottom to 1 / 3 of the length of the side of the pot body. The discharge port 9 is provided with a cover 10 that can close the opening 9. The material receiving box 2 is arranged at the discharge port 9 outside; the stirring and stirring member 8 includes a stirring shaft 81, and the top of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com