Arc surface machining tool for fuel rail kind product

A track and product technology, which is applied in the field of arc surface processing tooling for fuel track products, can solve problems such as energy waste and low production efficiency, and achieve the effects of improving processing efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

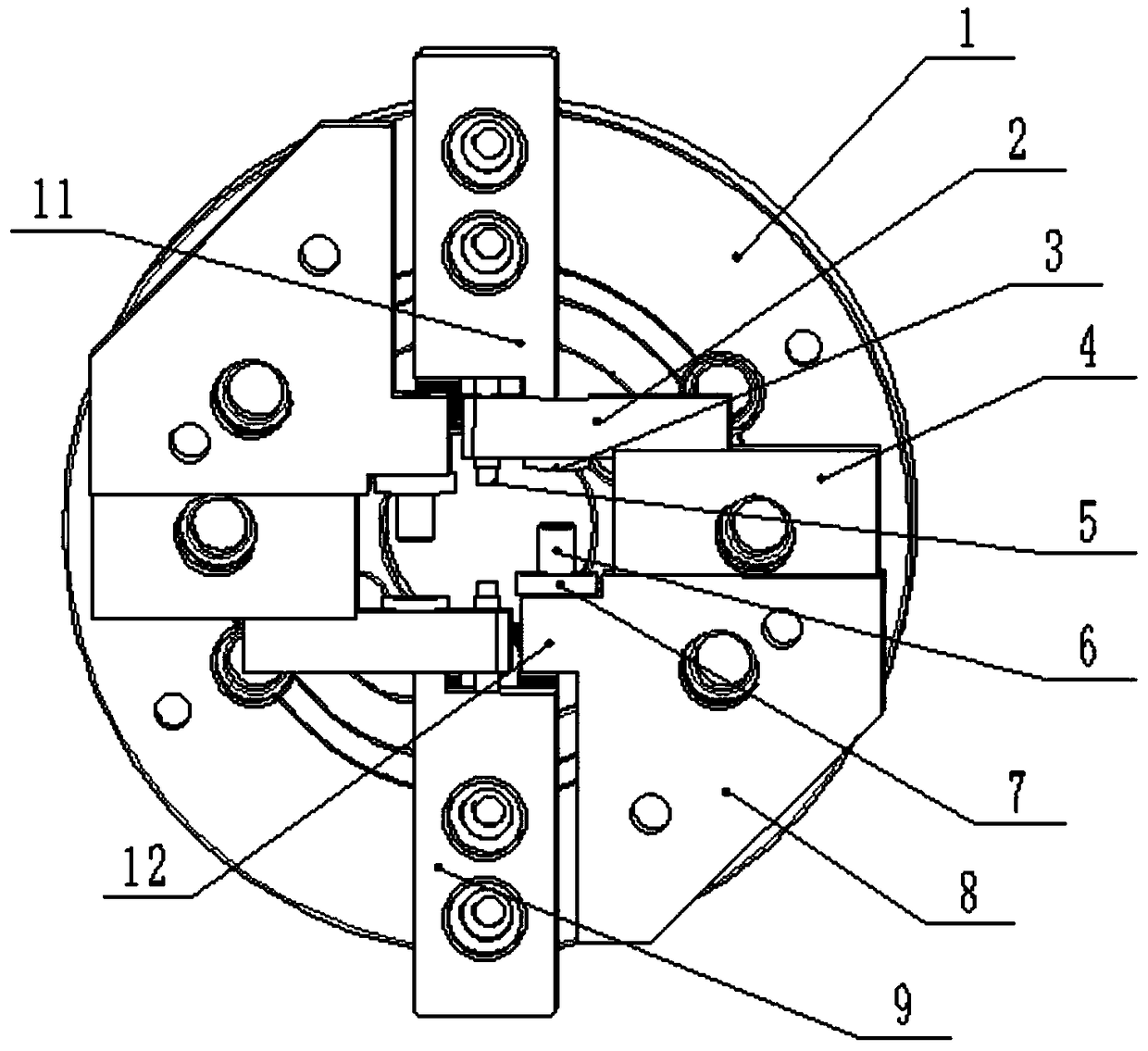

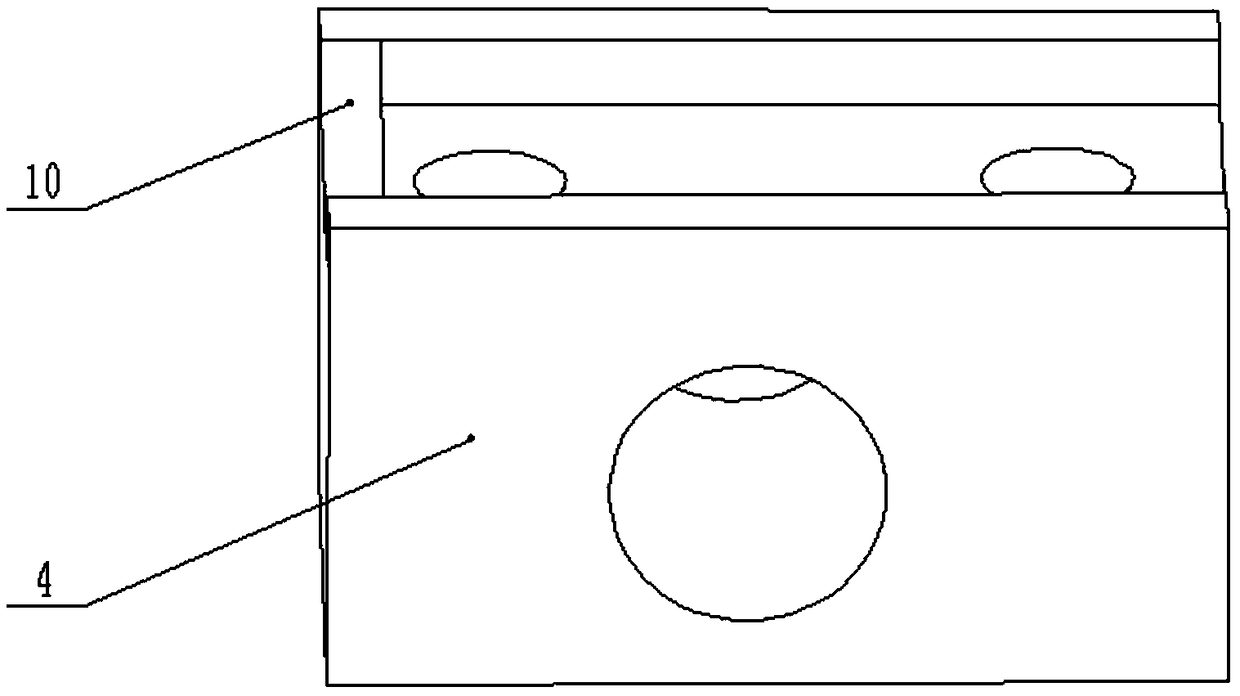

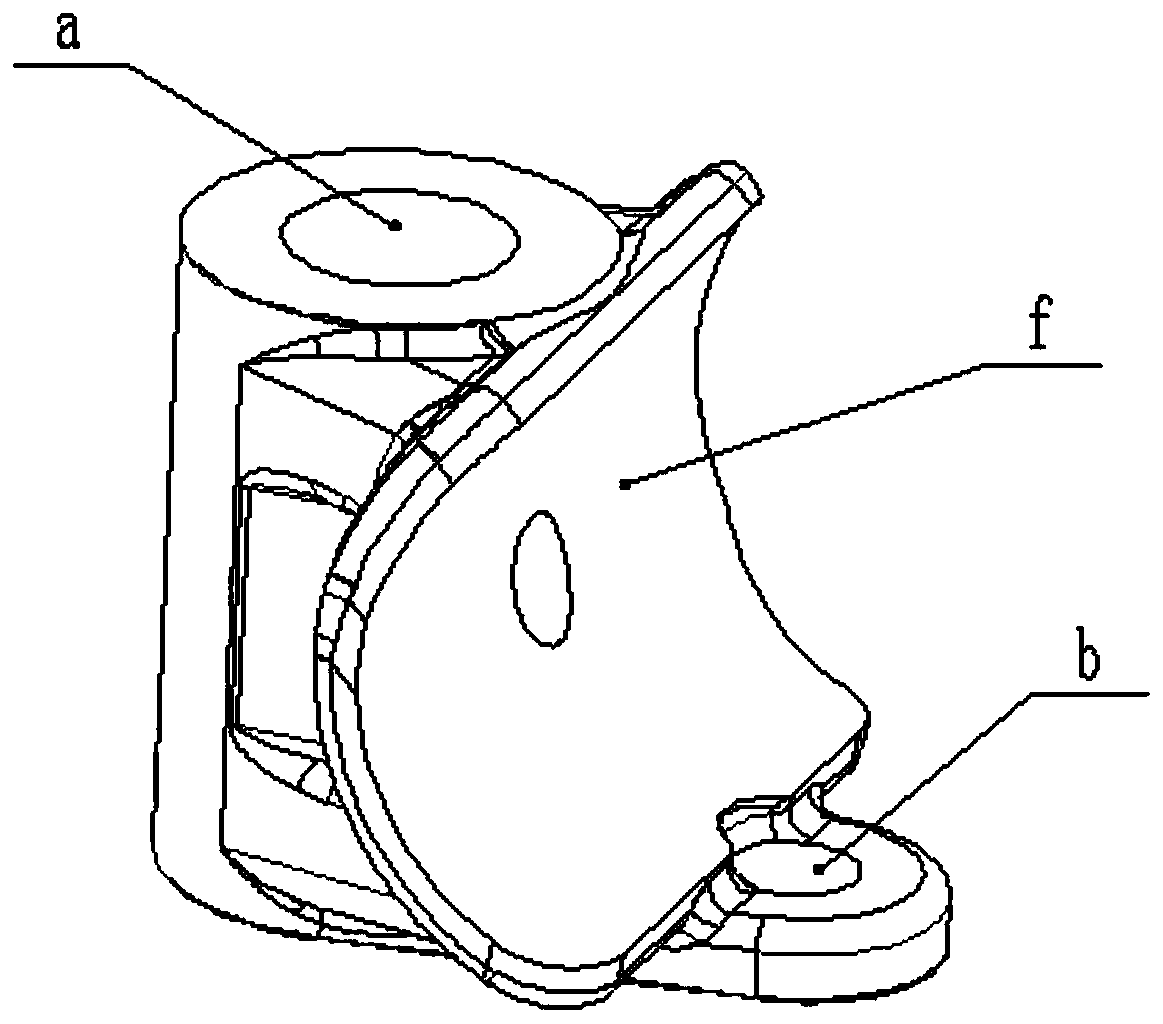

[0022] like Figure 1-2 As shown, a kind of arc surface processing tooling for fuel rail products includes a machine tool chuck 1. Two positioning devices and two machine jaws 9 are arranged on the machine tool chuck 1. The two positioning devices are mounted on the machine tool chuck. The disc 1 is arranged diagonally, and the two machine jaws 9 are arranged diagonally on the machine chuck 1. The two machine jaws 9 cooperate with the two positioning devices to position and clamp the workpiece. It is to make the processing arc surface of the part also set diagonally to form a quasi-circular surface. The processing tool just contacts the two arc surfaces at the same time for processing, which improves the processing efficiency and saves energy.

[0023] Two described positioning devices all comprise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com