Plastic solid waste recycling and processing device

A solid waste recycling technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problem of low separation efficiency of plastic bottles and paper products, achieve enhanced separation effect, improve efficiency and effect, and facilitate drying treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

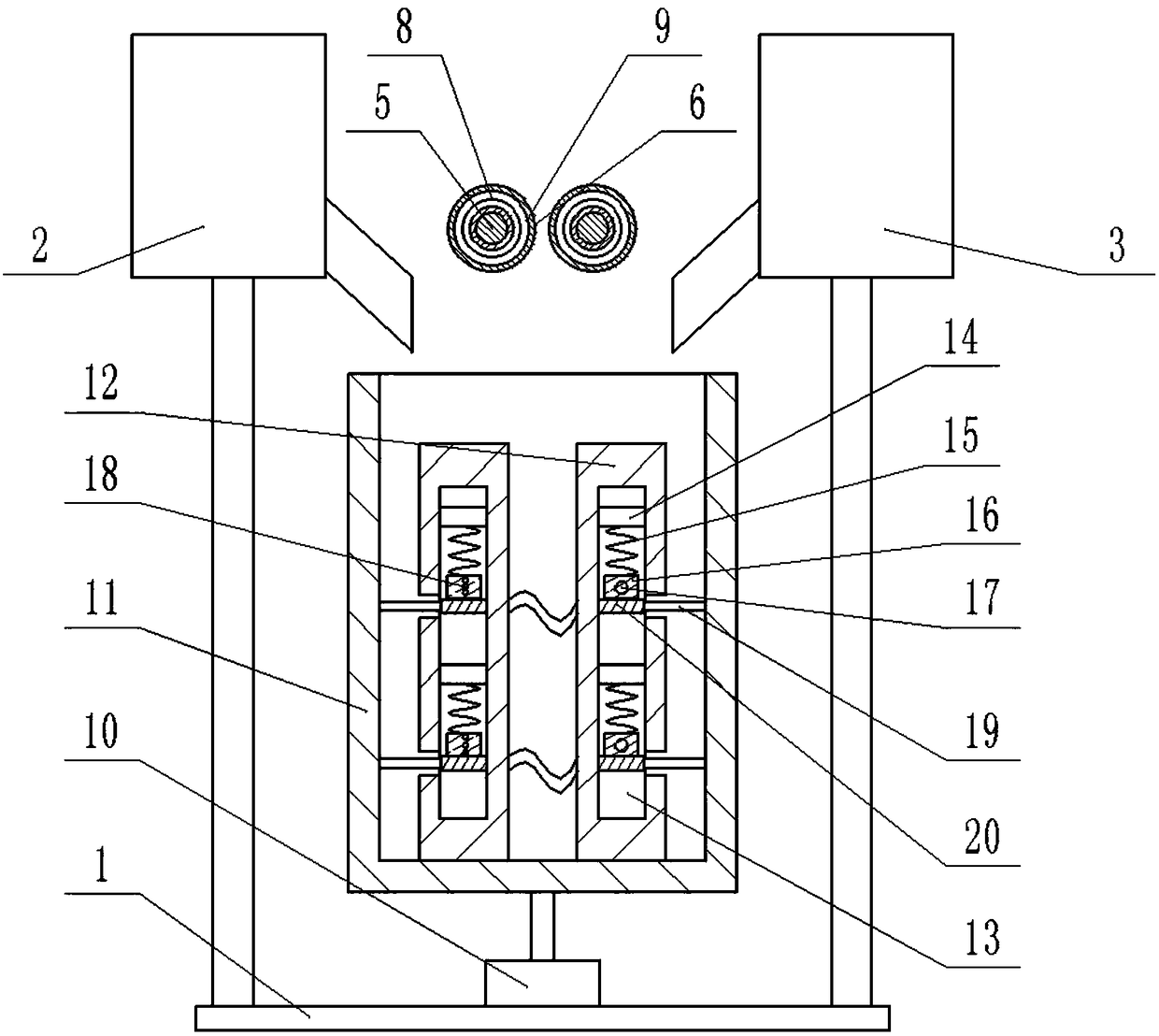

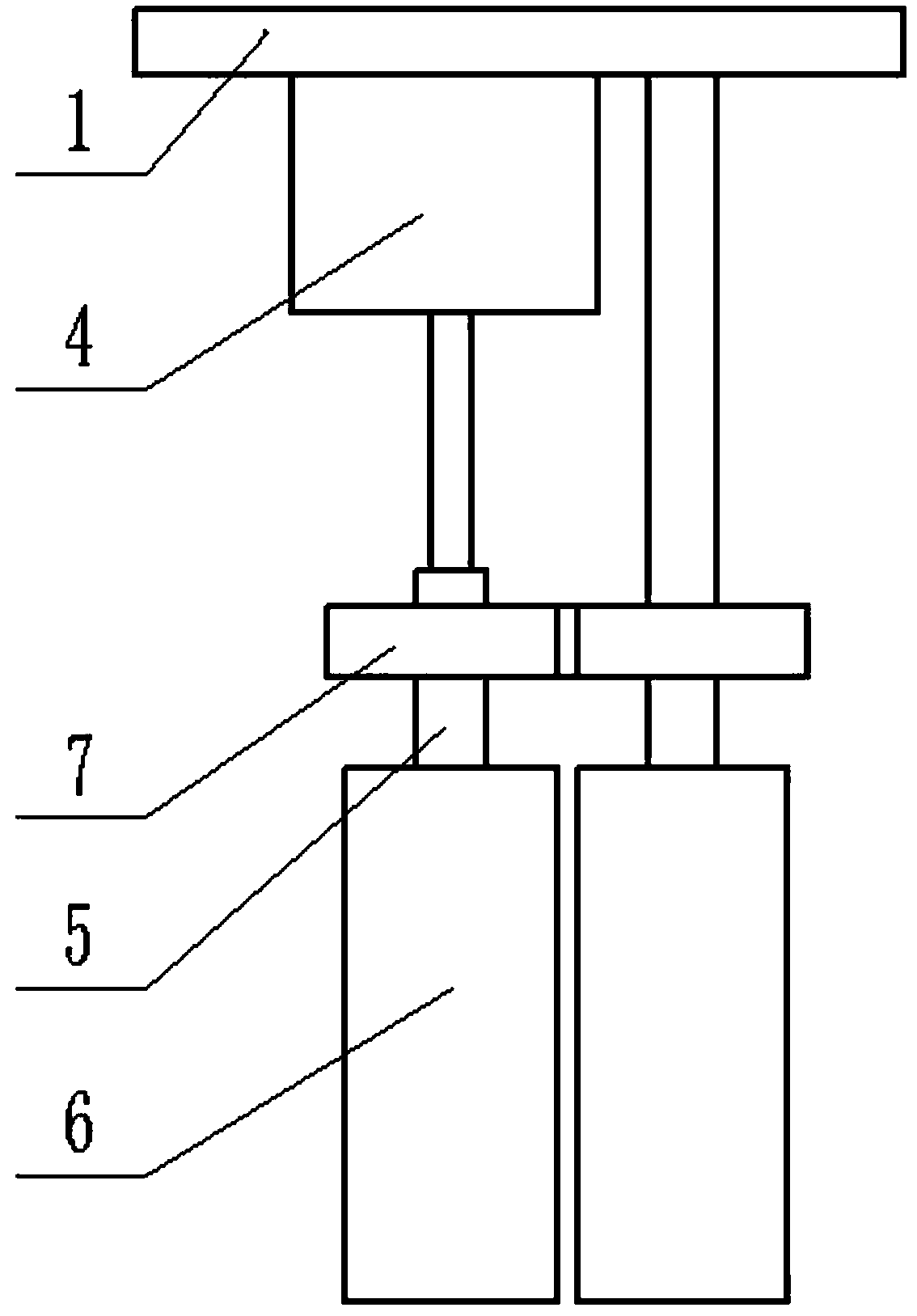

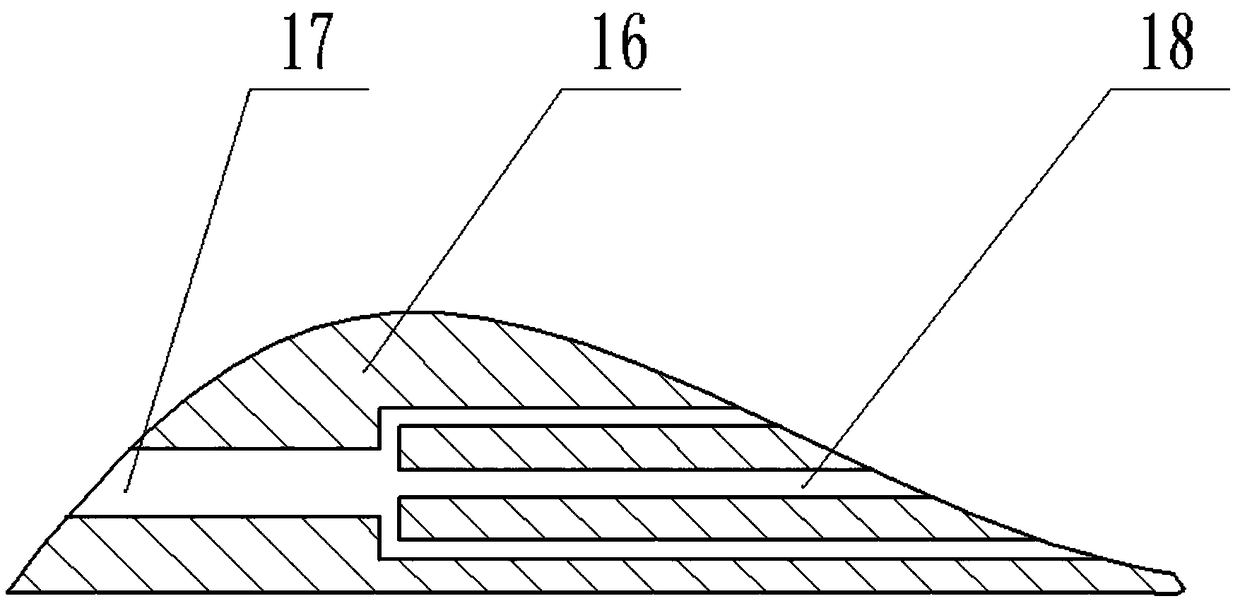

[0021] The reference signs in the accompanying drawings of the description include: frame 1, water storage tank 2, sand storage tank 3, first motor 4, roller shaft 5, roller 6, gear 7, heating wire 8, annular cavity 9, the first Two motor 10, mixing bucket 11, spoiler 12, through groove 13, spring plate 14, spring 15, spoiler block 16, first spoiler hole 17, second spoiler hole 18, pole 19, spoiler ring 20.

[0022] Such as figure 1 , figure 2 As shown, the plastic solid waste recycling treatment device in this embodiment includes a frame 1 and a first motor 4, the first motor 4 is horizontally arranged on the upper part of the frame 1, and the output end of the first motor 4 is coaxially connected to a The first roller shaft 5 is rotatably connected with another roller shaft 5 on the frame 1, and the two roller shafts 5 are coaxially provided with a gear 7, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com