A pneumatic booster type inter-stage separation mechanism-

A technology of inter-stage separation and pneumatic boosting, which is applied in the direction of motor vehicles, aerospace equipment, and aerospace vehicles, etc., can solve the problems of being in the wake of the upper-stage engine, increasing product costs, and being difficult to adopt, so as to achieve unlocking The separation is simple and easy to realize, the aerodynamic shape is good, and the structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and examples.

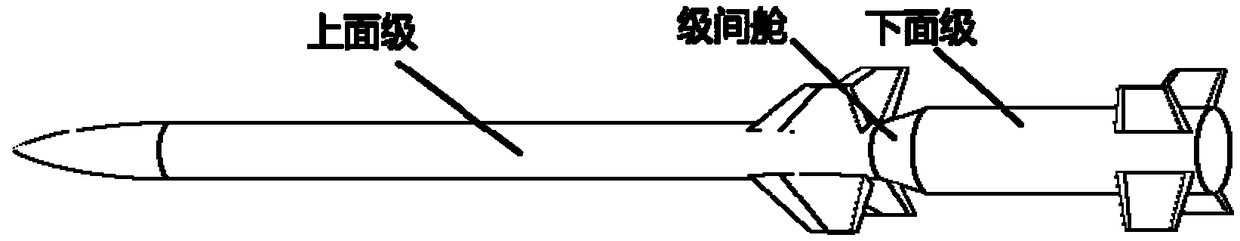

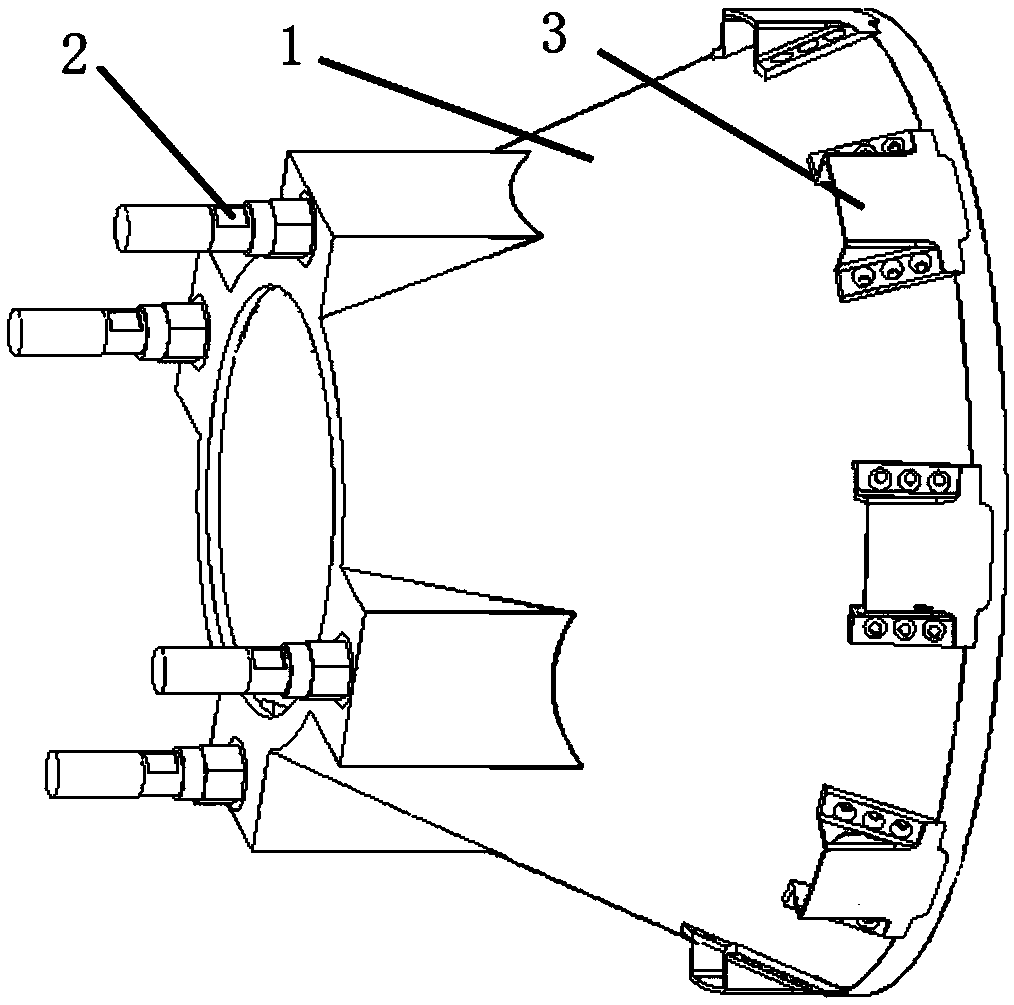

[0027] The invention provides a pneumatic pressurized interstage separation mechanism, such as figure 2 As shown, it includes an interstage compartment shell 1, an explosion bolt 2 and a pressurized cover 3.

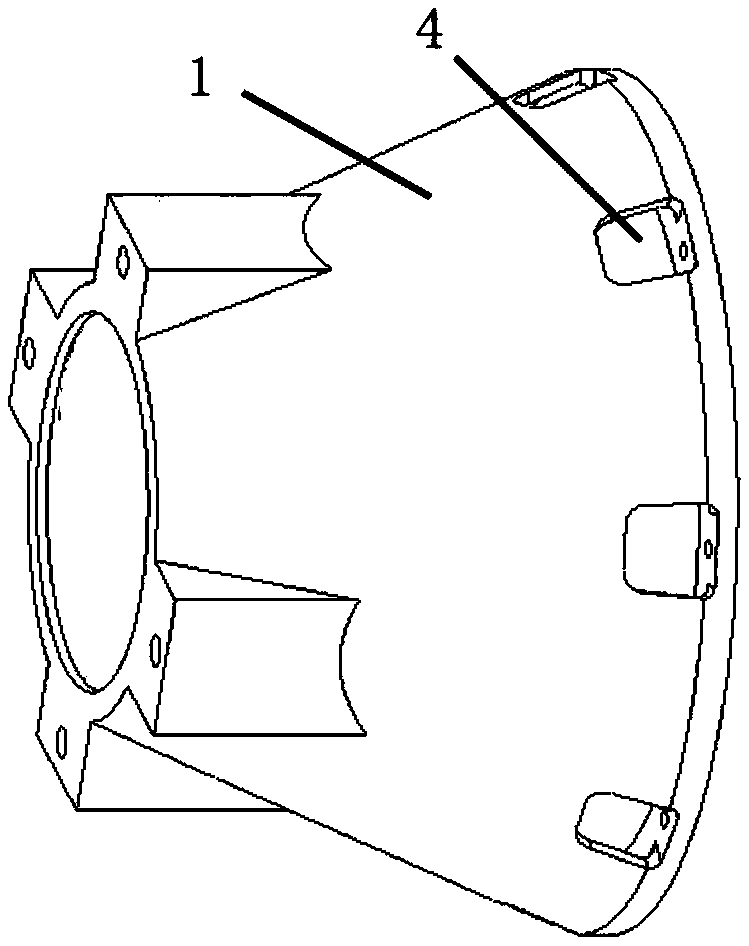

[0028] The interstage cabin shell 1 is located between the upper stage and the lower stage, and its main function is to connect the upper stage and the lower stage as a whole, maintain the aerodynamic shape of the rocket or missile during flight, and meet certain shape, strength and rigidity requirements . The connection surface between the interstage cabin shell 1 and the tail end of the upper stage is the interstage separation surface. The outer wall of the rear end of the interstage cabin shell 1 is uniformly provided with through holes 4 along the circumferential direction.

[0029] Explosive bolts 2 are arranged on the butt joint end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com