Straight insert shaping and packing machine and control method thereof

A packaging machine and controller technology, used in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of high production cost, low production efficiency, and many people are required for direct insertion, so as to reduce production costs and achieve stable production quality. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

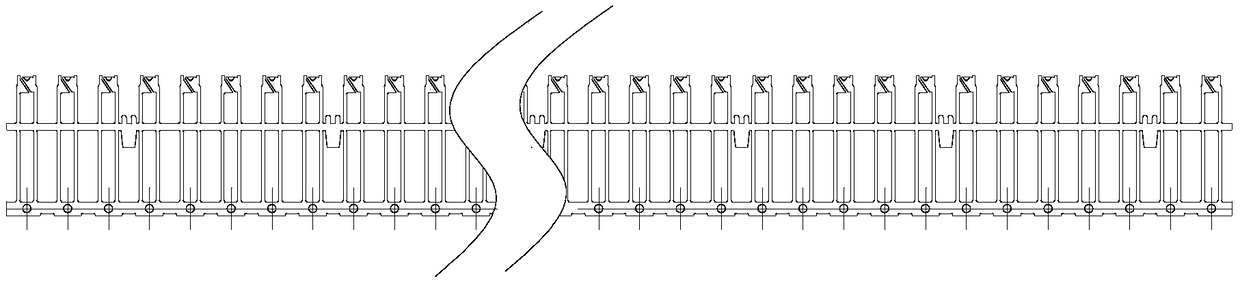

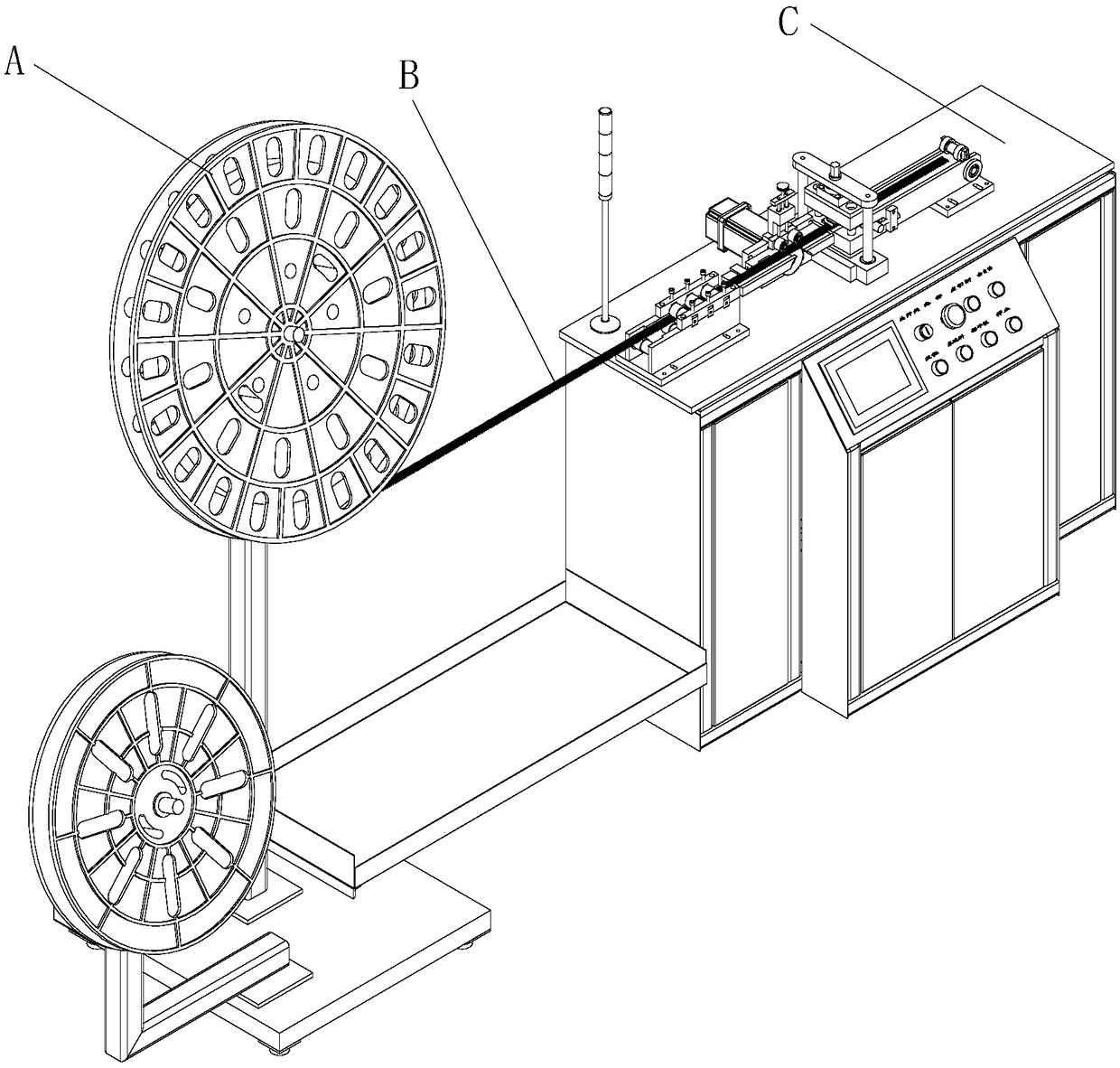

[0052] Such as Figure 4 As shown, the in-line shaping packaging machine 100 of this embodiment can be directly connected with the in-line film cutting machine to form an automated production line. The plastic disc 201 on the in-line film cutting machine winds the direct film 202, and is formed by cutting the stamping die. A certain length of single in-line film, these single in-line film are directly sent to the feeding mechanism 1 of the in-line plastic packaging machine 100.

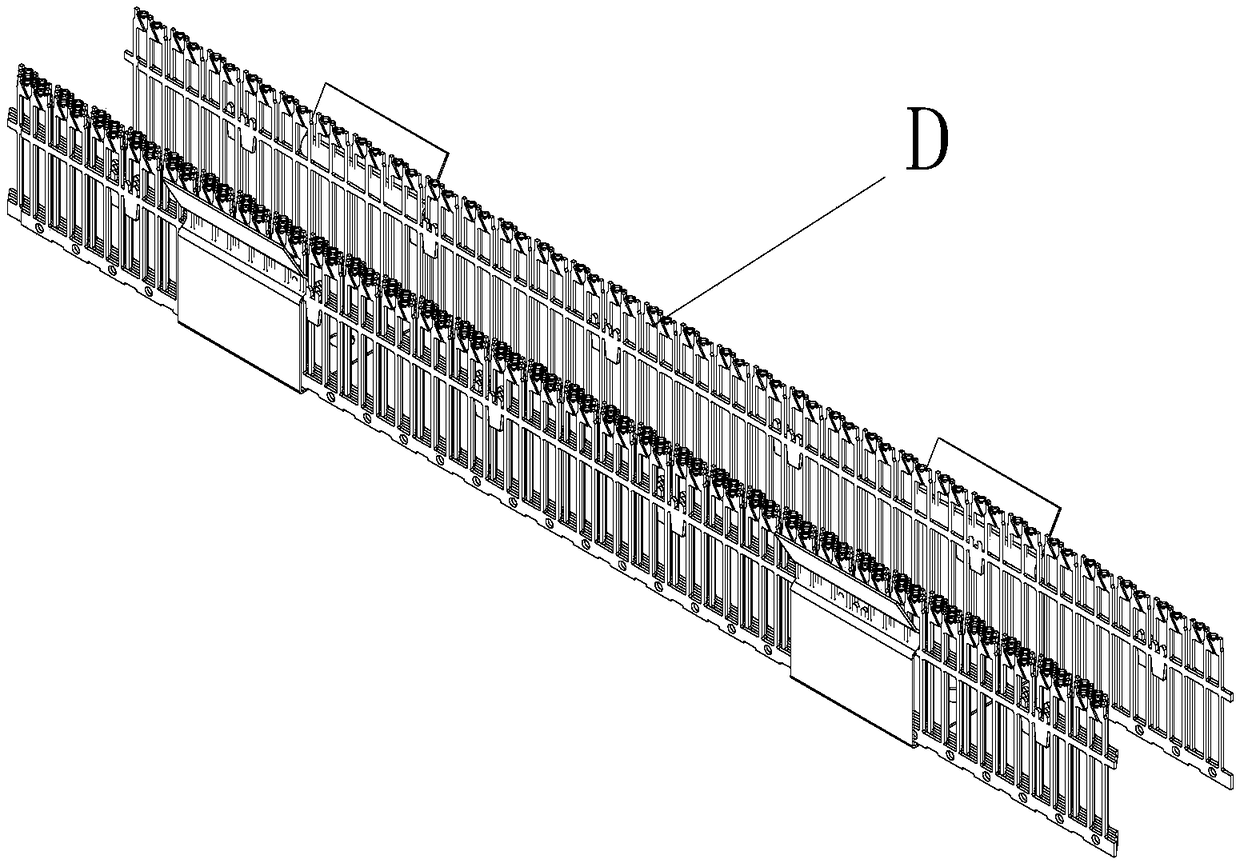

[0053] Such as Figure 5 to Figure 19 As shown, an in-line shaping packaging machine provided in this embodiment is characterized in that it includes a frame 10, a controller, and a material receiving mechanism 1 installed in the frame 10, a shaping mechanism 2, a discharging mechanism 3, The picking module 4 and the grabbing module 5, the controller controls the material receiving mechanism 1, the picking module 4, the shaping mechanism 2, the discharging mechanism 3 and the grabbing module 5 to wor...

Embodiment 2

[0071] This implementation provides the control method of the in-line shaping and packaging machine described in Embodiment 1, specifically as follows: a control method of the in-line shaping and packaging machine, which is characterized in that it includes the following steps:

[0072] Step 1: Receive the material, use the material receiving mechanism 1 to pick up a certain number of in-line chips, stack the certain number of in-line chips, rotate the stacked in-line chips by 90 degrees, and send them to the next station;

[0073] Step 2: Grab the stacked in-line sheets sent out in step 1 and place them in the shaping mechanism 2 for shaping;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com