Rubber strip winding machine

A winding machine and rubber strip technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problem of rubber strip tearing, avoid breakage, improve winding efficiency, and improve pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The rubber strip winder of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

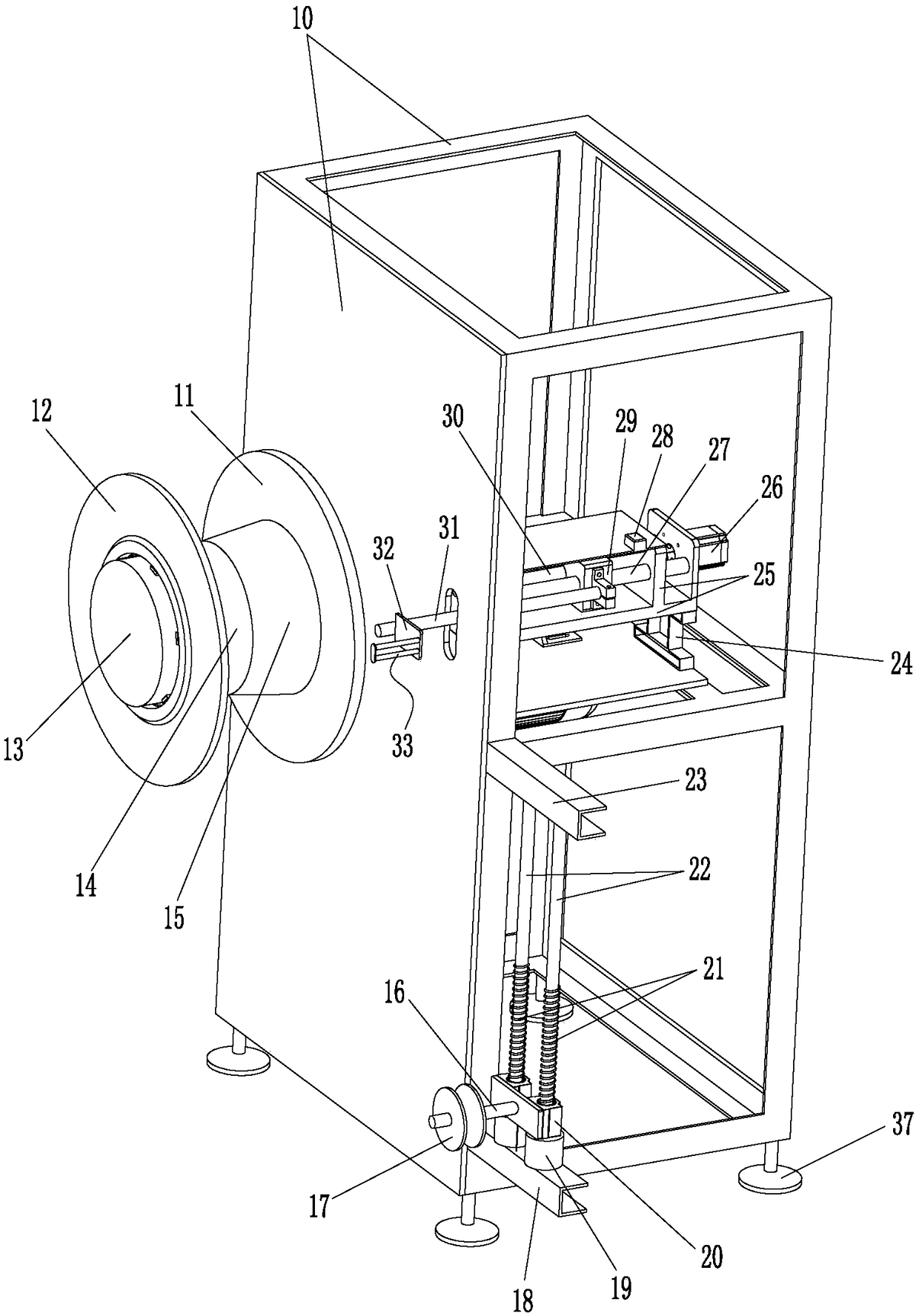

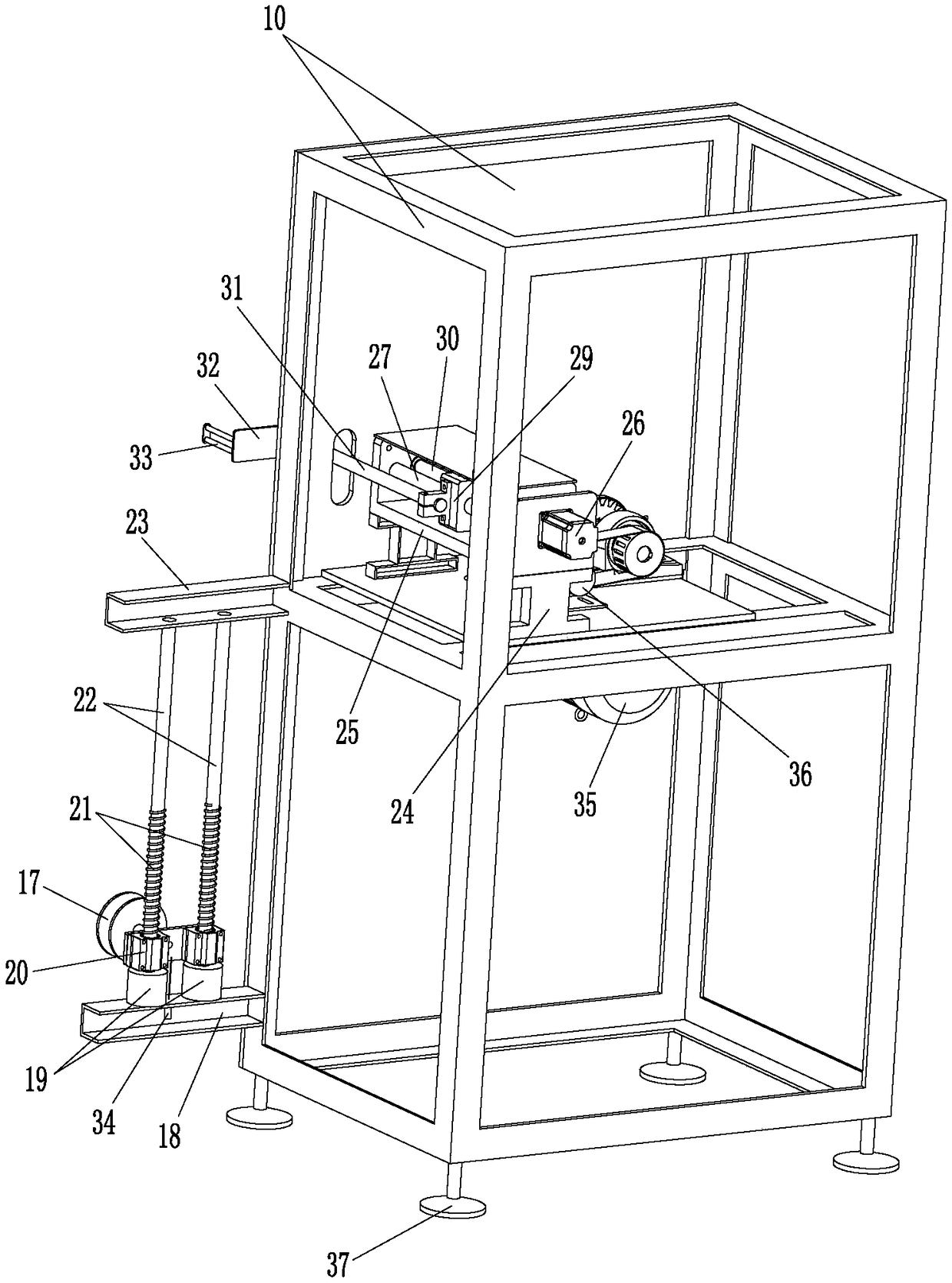

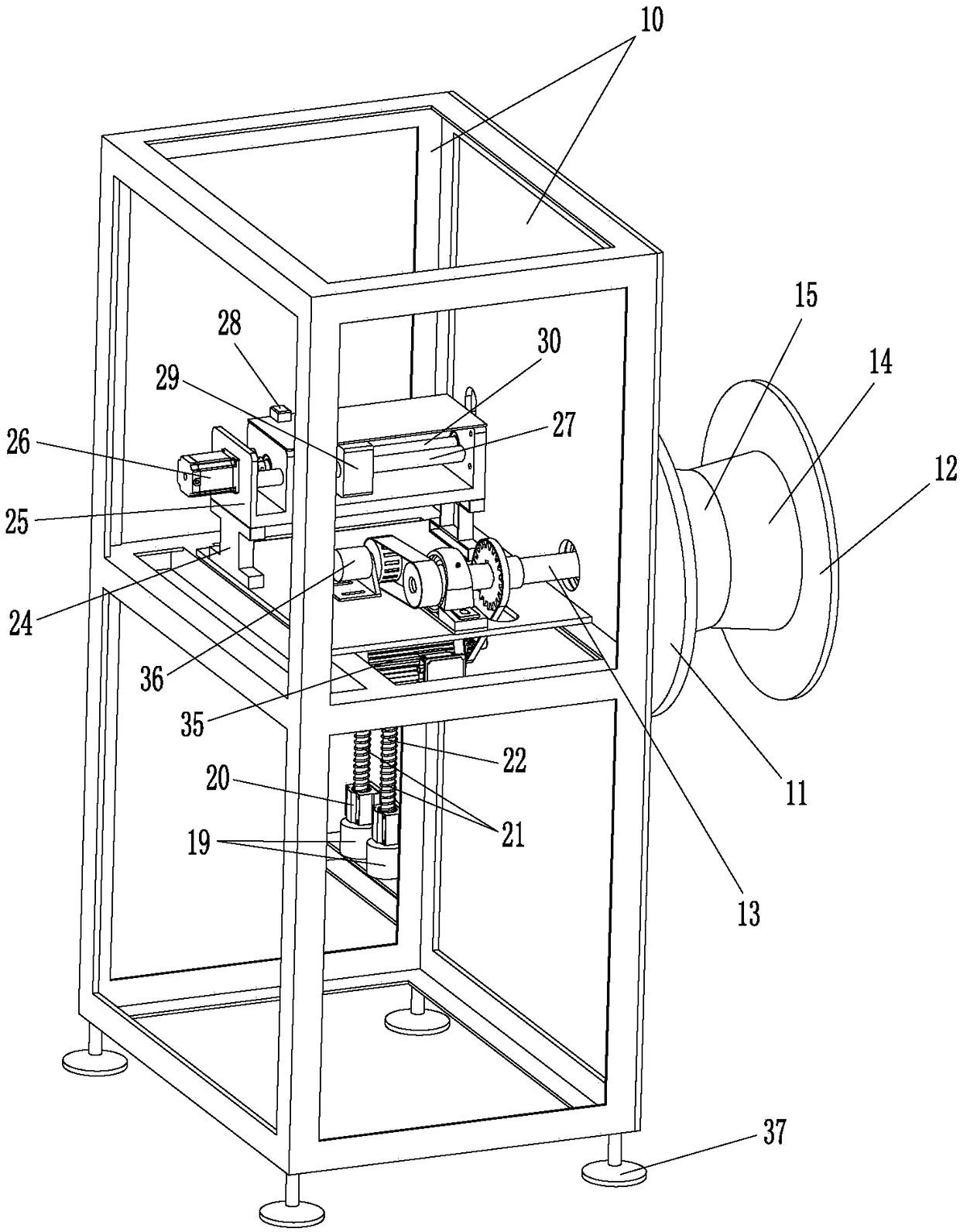

[0016] Such as figure 1 , figure 2 and image 3 As shown, in this specific embodiment, the rubber strip winding machine of the present invention includes a frame 10, a winding shaft 13, a winding motor 35 for driving the winding shaft 13 to rotate, and four bottoms installed at the bottom of the frame 10. Pin 37 also includes guide wheel 17, backguy sensor 34, sliding sleeve 20, guide rod 22, guide roller 33, support rod 31, slide block 29, guide rail 27, reset sensor 28, support seat 25, base 24, screw mandrel 30 and the stepper motor 26 used to drive the slider 29 to slide back and forth along the guide rail 27.

[0017] Rewinding shaft 13 is horizontally installed on the top of frame 10 by bearing and bearing seat, and winding motor 35 is contained in the afterbody of winding shaft 13, is connected with win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com