Fixing jig for earphone wires and processing technology for earphone wires using the jig

A technology for fixing fixtures and processing technology, which is applied in the manufacturing of circuit/collector parts, electrical components, cables/conductors, etc. It can solve the problems of low qualification rate, difficult control and low efficiency in the production process, and improve production efficiency. , Easy to operate, fixed and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0038] The longitudinal direction referred to in this specification refers to the extending direction of the wiring substrate and the wiring substrate, and the transverse direction refers to the direction perpendicular to the extending direction of the wiring substrate and the wiring substrate.

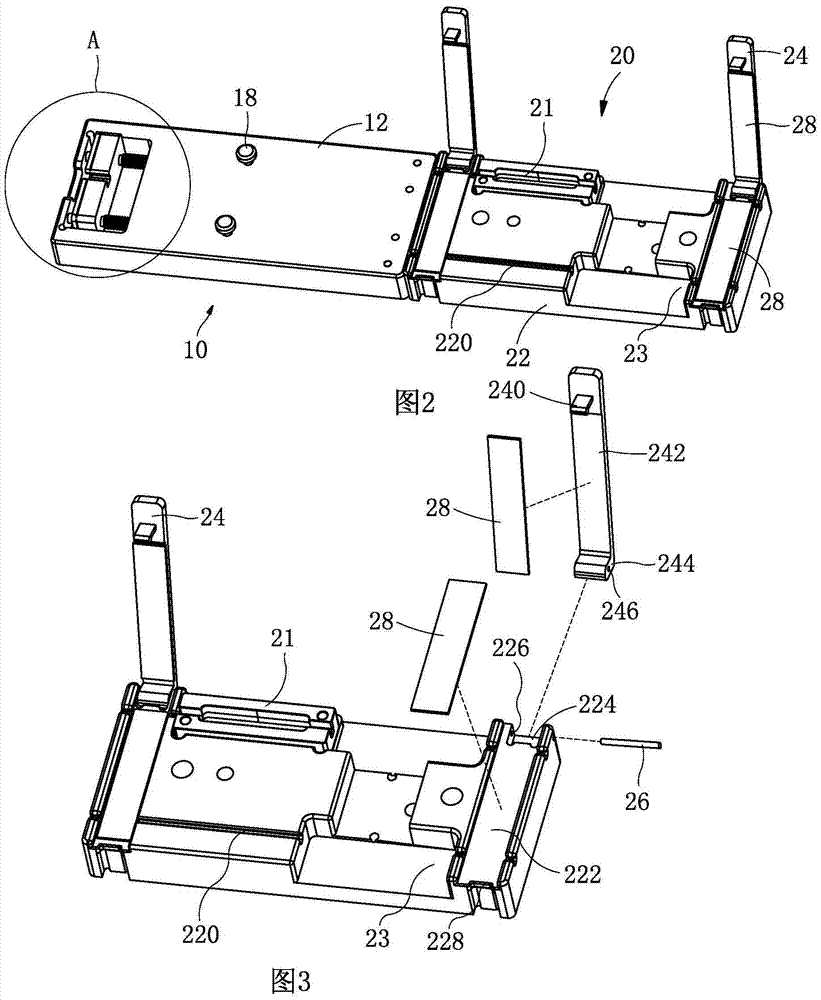

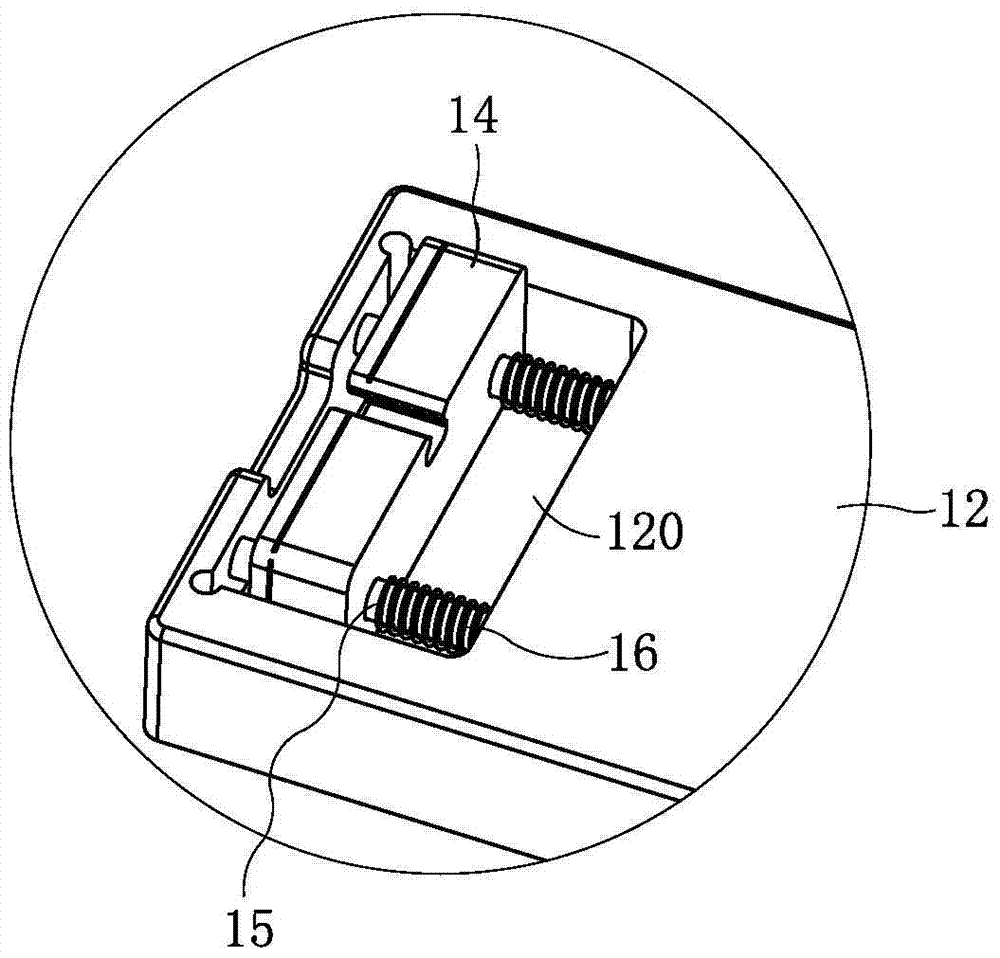

[0039] As shown in Figure 2, an earphone wire fixing jig includes a wire assembly 10 and a clamping assembly 20 connected together, the wire assembly 10 includes a rectangular wire substrate 12, and the wire clamping assembly 20 includes a rectangular wire clamping substrate 22. The width of the lead substrate 12 is the same as that of the clamp substrate 22, and one end of the lead substrate 12 is connected to one end of the clamp substrate 22, that is, one short side of the lead substrate 12 is connected to one short side of the clamp substrate 22 , so that the wire assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com