Electrochemical thermal corrosion preparation method and microporous copper foil of a kind of microporous battery copper foil

A chemical corrosion and electrochemical technology, applied in the field of electrochemical hot corrosion preparation, can solve problems such as affecting coating and slurry seepage, and achieve the effect of solving adhesion, improving adhesion and improving activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

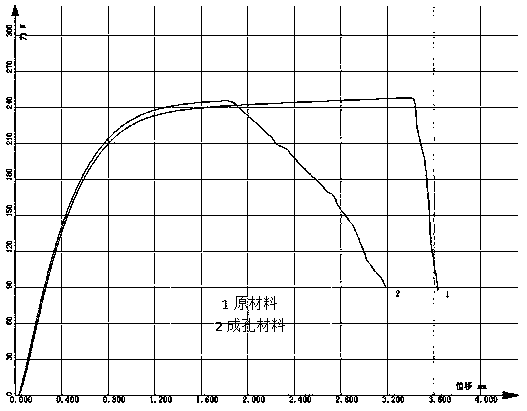

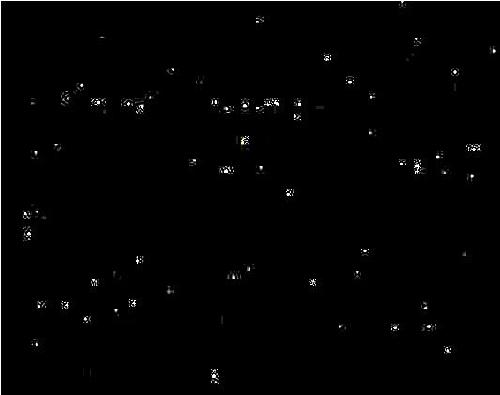

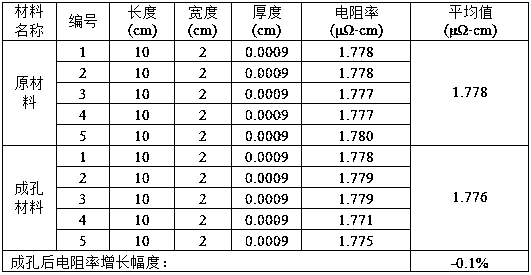

[0027] A method for preparing a high-performance lithium battery microporous copper foil by electrochemical thermal corrosion is carried out according to the following steps:

[0028] 1) Clean the surface of the rolled battery copper foil to remove the lubricant: the composition of the first cleaning solution is 10g / L NaOH, 10g / L NaOH 2 CO 3 , 40g / L of Na 3 PO 4 , the temperature of the first cleaning solution is kept at 45±2°C, the rolled copper foil is passed through the first cleaning solution, and the time of keeping in the first cleaning solution is 8s.

[0029] 2) Press the cleaned copper foil into the chemical etching solution: the composition of the chemical etching solution is: 1.5mol / L HCl, 1mol / LC 2 h 2 o 4 , 0.1mol / L NH 4 Cl, 1mol / L FeCl 3, the temperature of the chemical etching solution is kept at 45±2°C, the etching tank is used as the cathode, the copper foil is used as the anode, and 48V DC is applied for etching. The residence time of the copper foil ...

Embodiment 2

[0036] 1) Clean the surface of the battery copper foil: there are attachments on the surface of the rolled battery copper foil, which have an adverse effect on the formation of holes in the copper foil, and the copper foil needs to be cleaned by the first cleaning solution. Described first cleaning liquid is made of 15g / L NaOH, 15g / LNa 2 CO 3 , 15g / L Na 3 PO 4 Composition, the temperature of the first cleaning solution is kept at 45±2°C, the rolled copper foil is passed through the first cleaning solution, and the time of keeping in the first cleaning solution is 7s.

[0037] 2) All the cleaned copper foils are immersed in the chemical corrosion solution, so that the corrosion solution flows on the upper and lower surfaces of the copper foil in a circular flow mode, so as to achieve uniform corrosion on the upper and lower surfaces. The corrosion tank is used as the cathode, the copper foil is used as the anode, and 6V DC is added for corrosion. The DC can also be set to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com