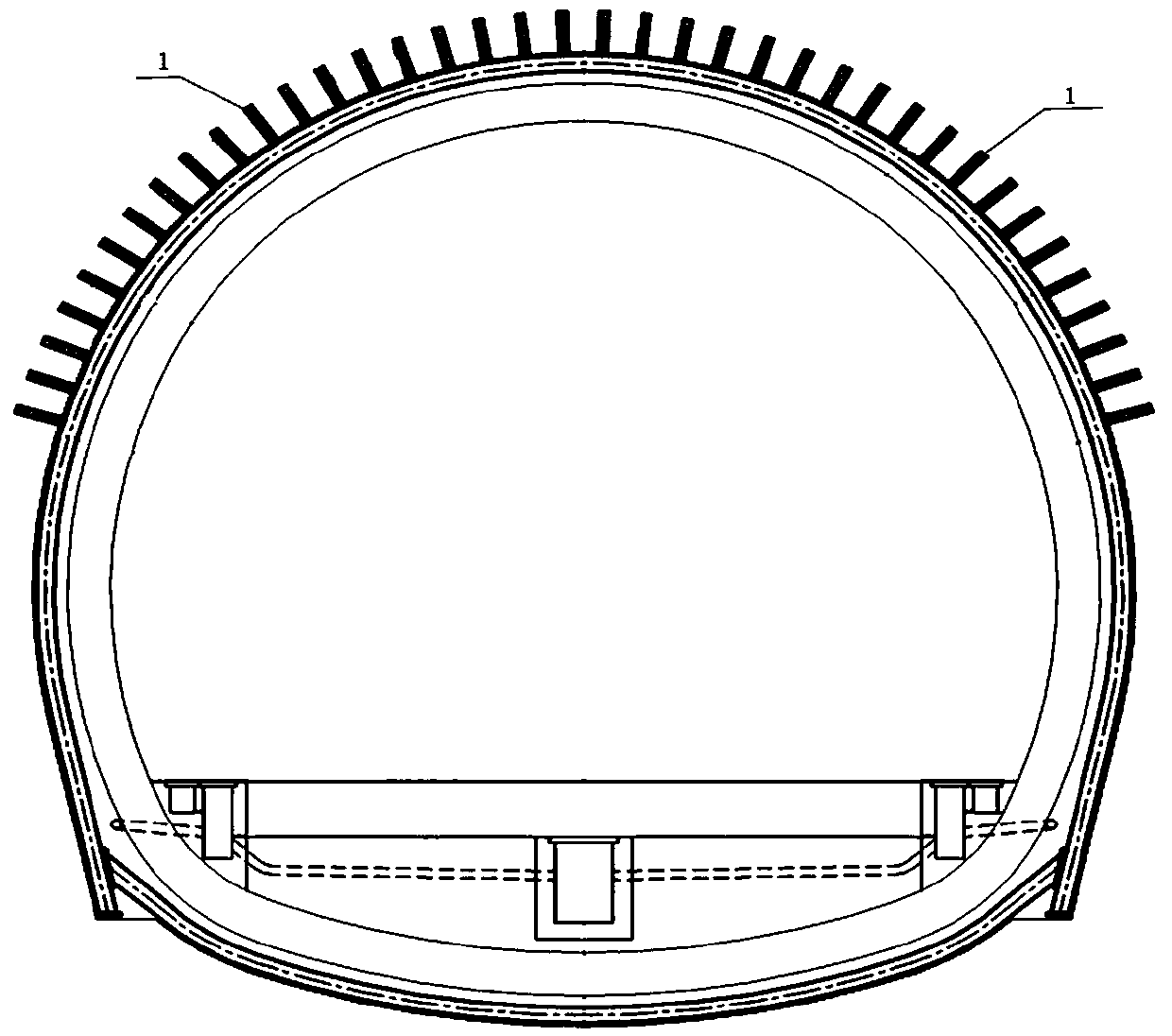

The Construction Method of Advance Small Conduit Entry and Exit Hole in Rock Tunnel

An advanced technology of small conduits and access holes, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of difficulty in meeting the construction principles of the new Austrian method, large disturbance of the surrounding rock at the entrance of the tunnel, and long construction period, so as to improve construction efficiency, The effect of reducing investment and reducing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The construction method of the advanced small conduit entry and exit hole of the rock tunnel includes the following steps:

[0026] (1) Use the total station to accurately set out the drilling hole position on the tunnel excavation contour line and mark it with red paint:

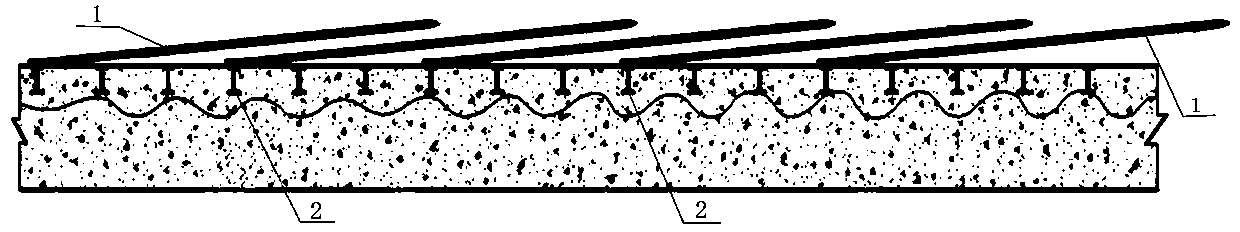

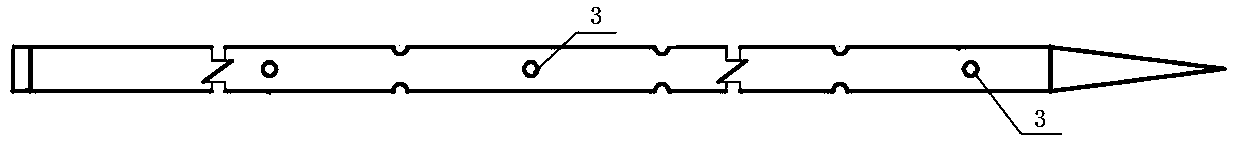

[0027] (2) Use the YT28 drilling rig to drill holes. The drilling direction should be straight. The drilling depth and diameter should match the leading small conduit. The sand in the hole is blown out;

[0028] (3) Pass the small lead pipe through the steel frame, hammer it or push it in through the drilling rig, the jacking length is not less than 90% of the length of the small lead pipe, and the outer insertion angle of the small lead pipe is 5-10°. Condition adjustment, but not > 10°, the circumferential distance is 40cm, and the sand and gravel in the leading small duct are blown out with high-pressure air, and the exposed part of the leading small duct should be firmly welded to the steel fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com