Smoke outlet structure and power station

A technology for smoke vents and power stations, which is applied in exhaust gas devices, combustion product treatment, combustion methods, etc., can solve the problems of large influence distance and influence the thermal concealment of the whole set of equipment, etc., so as to improve the concealment and speed up the heat exchange process. , the effect of large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

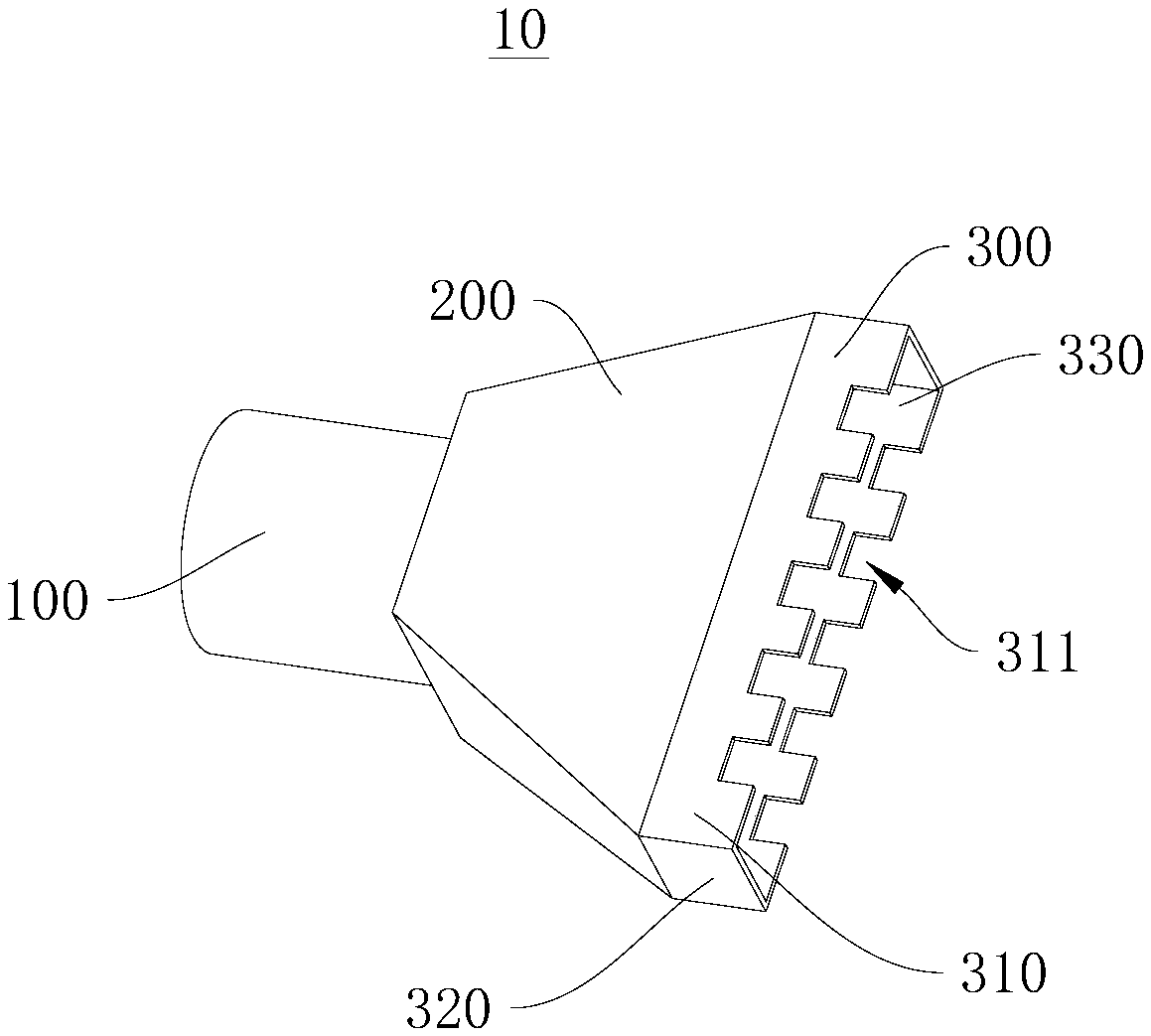

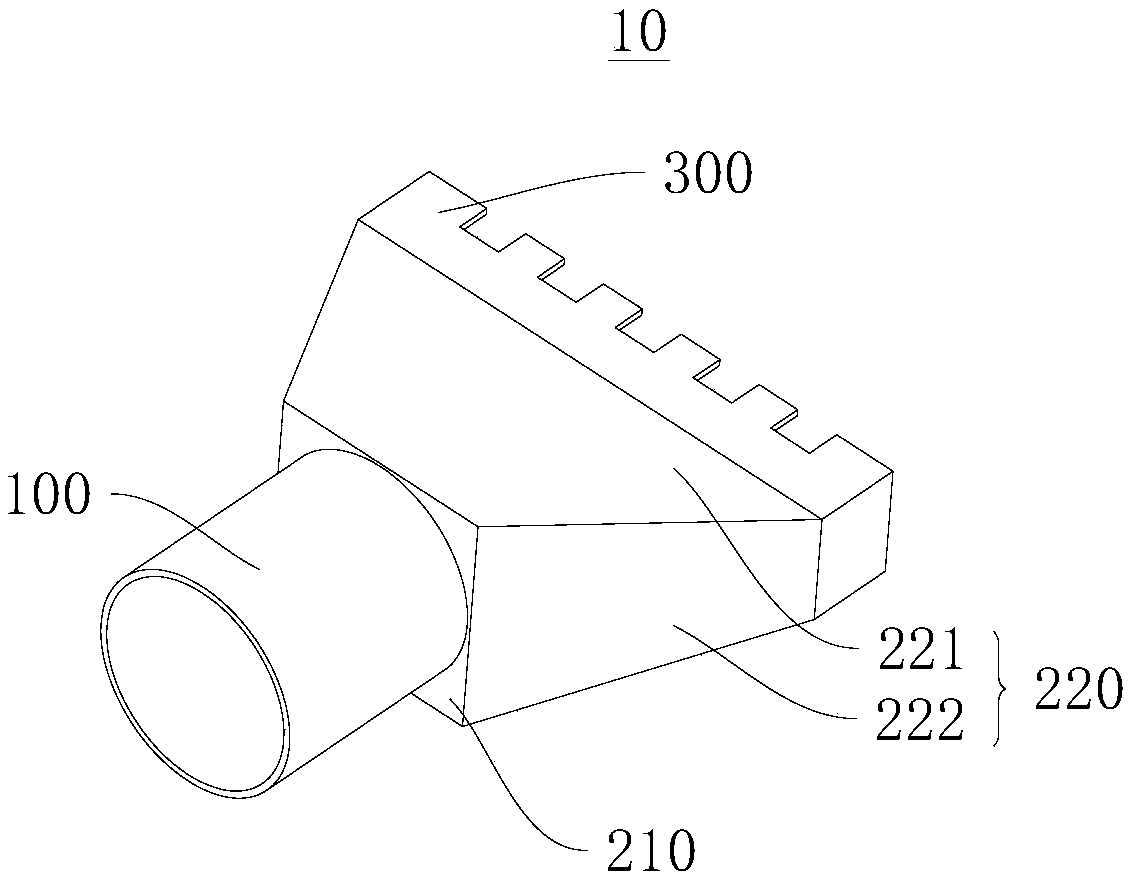

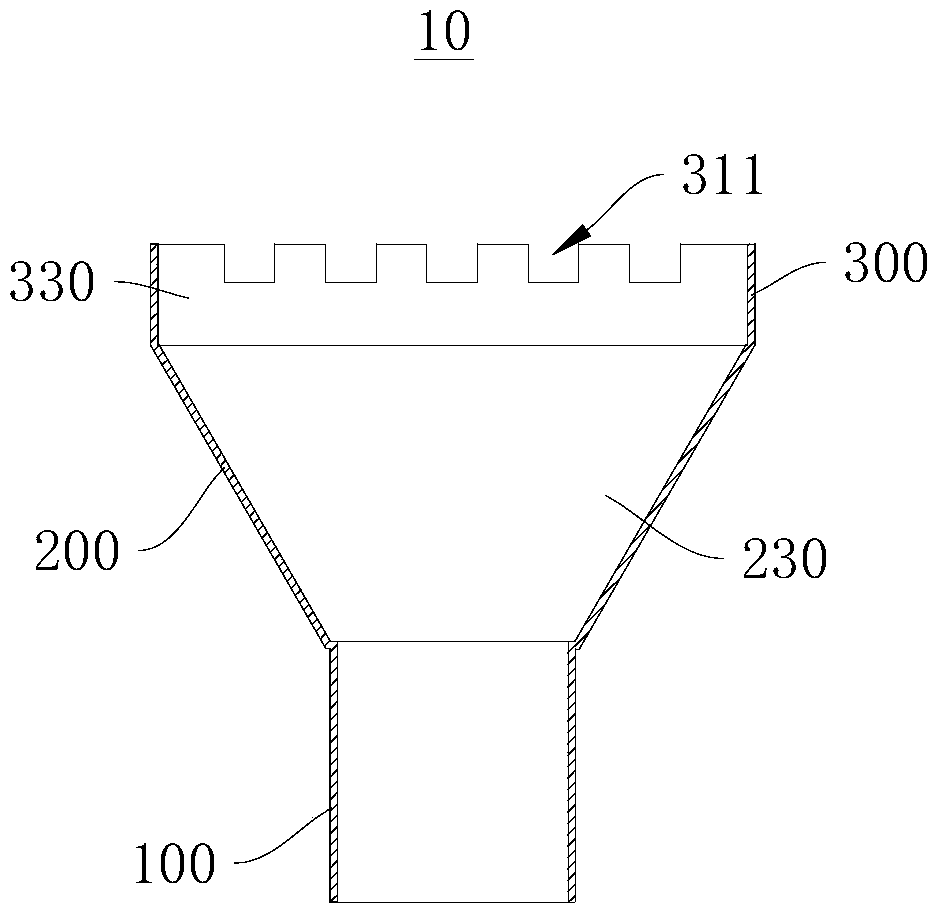

[0033] see figure 1 , the present embodiment provides a smoke outlet structure 10, which is applied to a power station (not shown in the figure) and is used to guide the smoke exhaust of the power station. The smoke outlet structure 10 can be cooled quickly, and the risk of being detected by infrared detection can be avoided.

[0034] Wherein, the power station includes a main body of the power station (not shown in the figure) and the above-mentioned smoke outlet structure 10, the main body of the power station operates and generates current, and the smoke outlet structure 10 is connected to the main body of the power station, and the smoke outlet structure 10 is used for exhausting the main body of the power station. The smoke is guided to ensure that the smoke generated by the main body of the power station can be discharged to the designated position in a designated way.

[0035] Please refer to figure 1 , figure 2 and image 3 , the smoke outlet structure 10 includes...

no. 2 example

[0052] This embodiment provides a power station (not shown in the figure), which adopts the smoke outlet structure 10 provided in the first embodiment, and the power station can be cooled rapidly, and the risk of being detected by infrared detection can be avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com