Machine vision-based stainless steel soup ladle defect detection method

A defect detection and machine vision technology, applied in the direction of optical defect/defect, instrument, measuring device, etc., can solve the problems of image information loss and inconspicuous effect, and achieve the purpose of enhancing useful information, suppressing noise interference, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

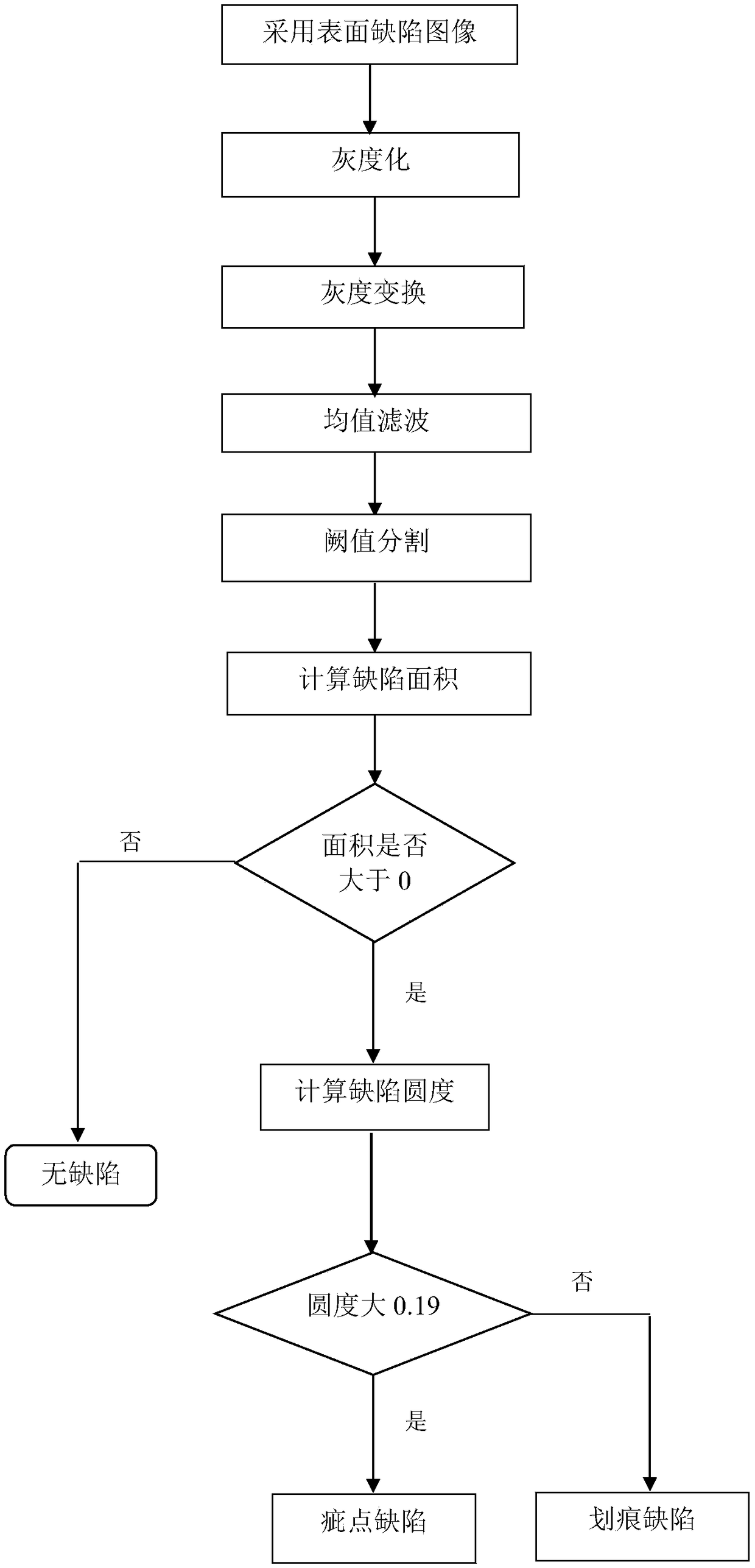

[0029] Such as figure 1 As shown, a machine vision-based defect detection method for stainless steel spoons includes the following steps:

[0030] S1), using the camera to collect the image of the surface defect of the stainless steel spoon to be detected,

[0031] Among them, the actual specification of the soup spoon is 20.5cm in length and 4.0cm in width. Since the defects and scratches are very small, a CMOS camera with an area array of 4 million pixels and a resolution of 2048 pixels × 2048 pixels is used. The size is 5.5um×5.5um; the lens adopts OPTART-M2-65 lens, its working distance is 35dm, and the optical magnification is 2; because the surface of the stainless steel spoon is highly reflective and easy to image, the lighting method uses a red tunnel-type light source , while using the Yamaha manipulator as motion control;

[0032] S2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com