High-performance cable for robot

A high-performance, robotic technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of not being able to check the inside of the cable, being easily damaged, and not being able to be removed at will, so as to prevent moisture from entering, and avoid disassembly and reinstallation , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

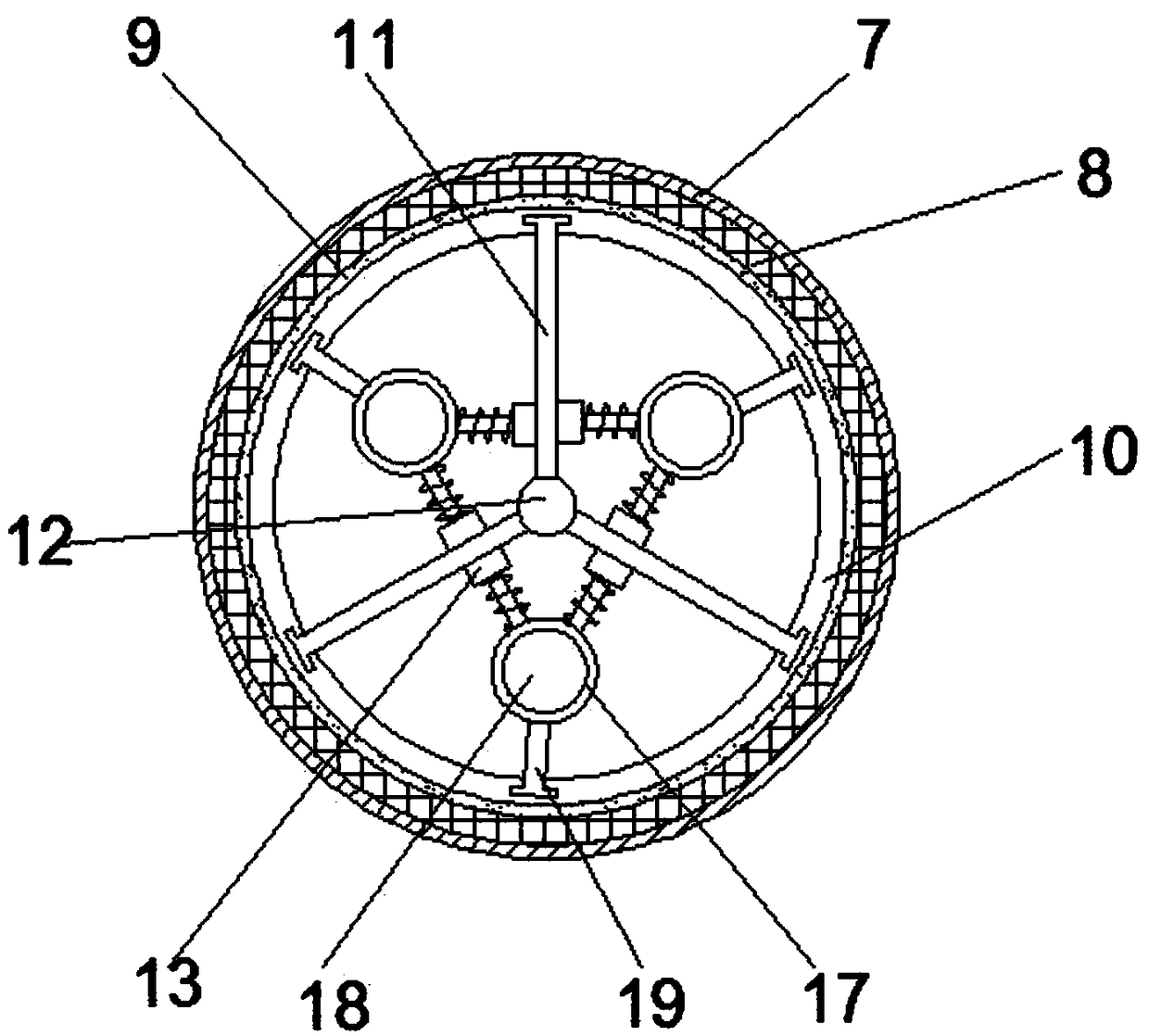

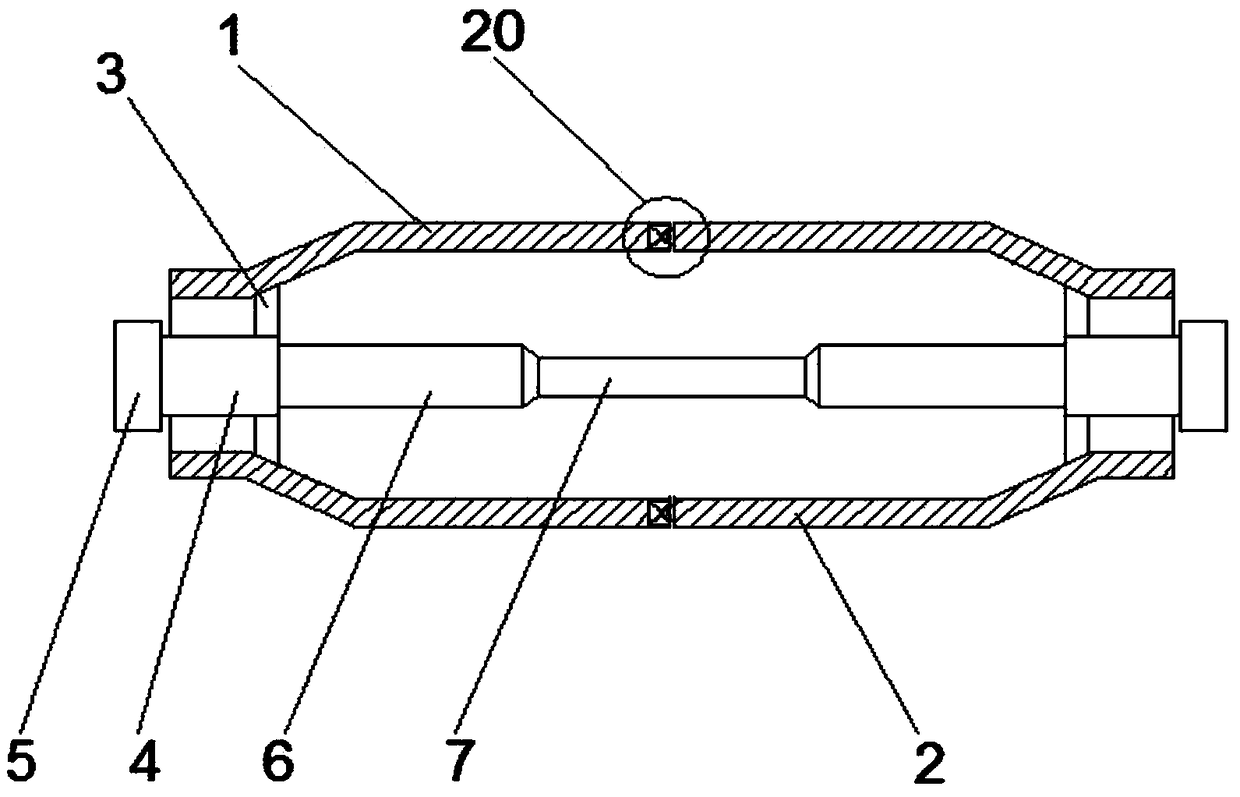

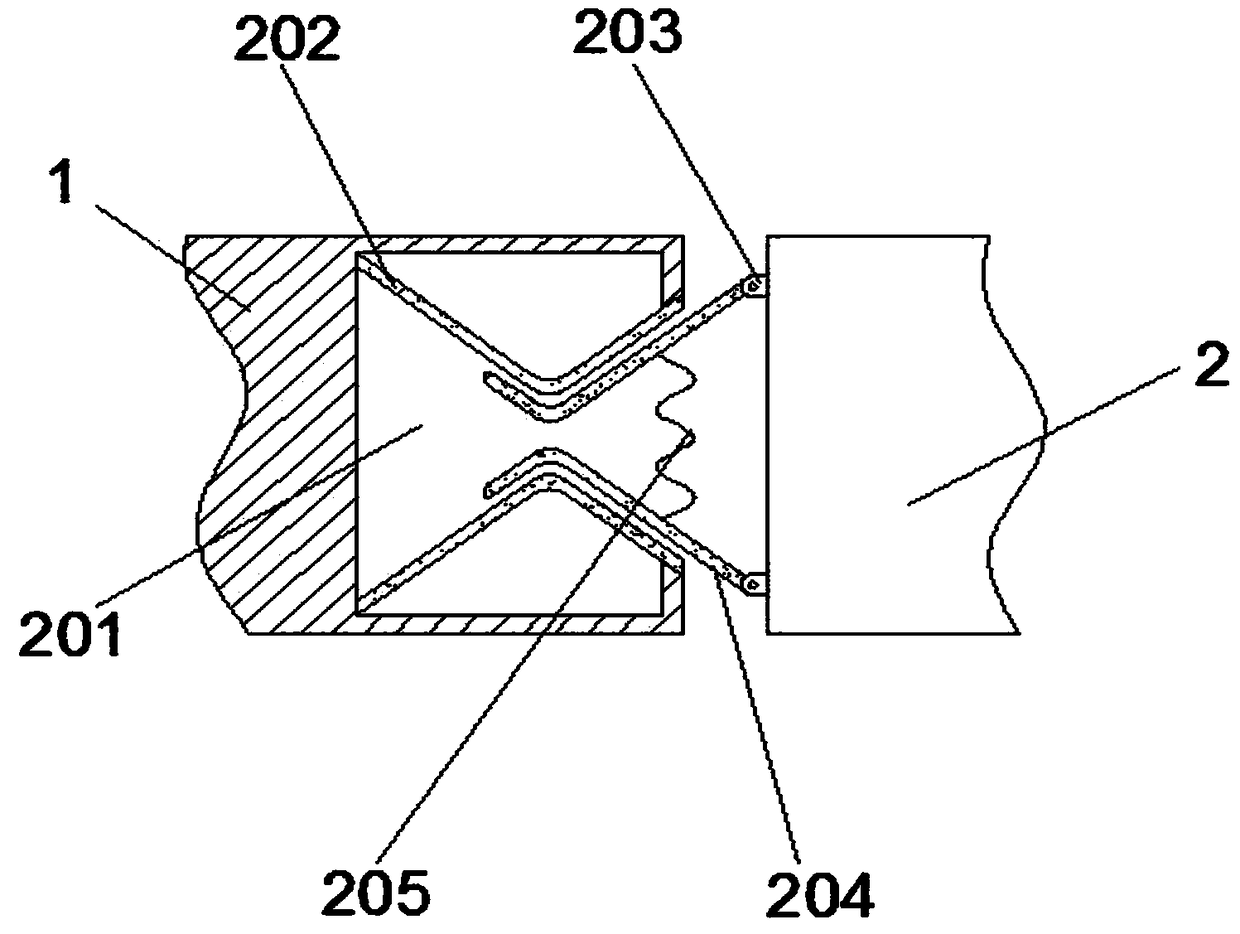

[0023] Such as Figure 1-Figure 6 As shown, a high-performance robot cable proposed by the present invention includes an intermediate connector, the intermediate connector includes a left outer shield 1, the upper and lower sides of the right end of the left outer shield 1 are connected to the right outer shield 2 through a buckle device 20, and the buckle device 20 includes a cavity 201, the upper and lower sides of the left side wall of the cavity 201 are provided with fixed soft rods 202, the upper and lower parts of the left end of the right outer shield 2 are provided with a number of movable bolts 203, and movable soft rods 204 are arranged on the movable bolt 203, A telescopic spring 205 is set between the two movable soft rods 204, and the left outer shield 1 and the right outer shield 2 are both provided with a semiconductor layer 4, and both the left outer shield 1 and the right outer shield 2 pass through the stress cone 3 and the semiconductor layer 4. connection, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com