Protein peptide powder production device convenient for adjustment and use

A production equipment and protein technology, applied in the direction of food science, etc., can solve the problem of wasting working time and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

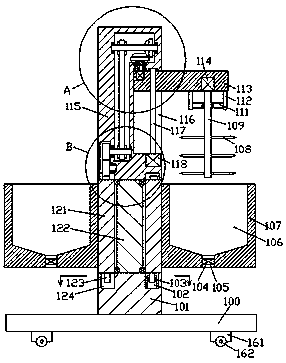

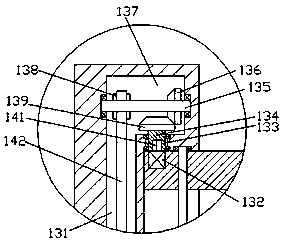

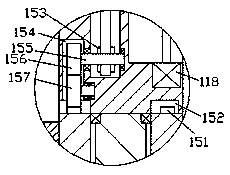

[0015] Combine below Figure 1-4 The present invention will be described in detail.

[0016] refer to Figure 1-4 According to an embodiment of the present invention, a protein peptide powder production equipment that is conveniently adjusted and used includes a bracket 100, a column 101 is fixed at the center of the top of the bracket 100, and a column 101 is fixed at the center of the top of the column 101. There is a rod body 122, the outer circumference of the rod body 122 is rotated and fitted with a swivel ring 121, and the left and right sides of the swivel ring 121 are symmetrically fixed with a storage box 107, and the bottom end of the swivel ring 121 and the top end of the cylinder 101 There is a limit device, the top end of the rod body 122 is fixed with a lifting frame 115, the bottom end surface of the lifting frame 115 is provided with a circular groove 152, and the top end surface of the swivel ring 121 is fixed with a circular groove 152 extending into the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com