Fracture external fixing rack installation assembly

A technology for installing components and fixing frames, which is applied in the field of fracture locating frames, and achieves the effects of simple structure, good recovery and simplified operation workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

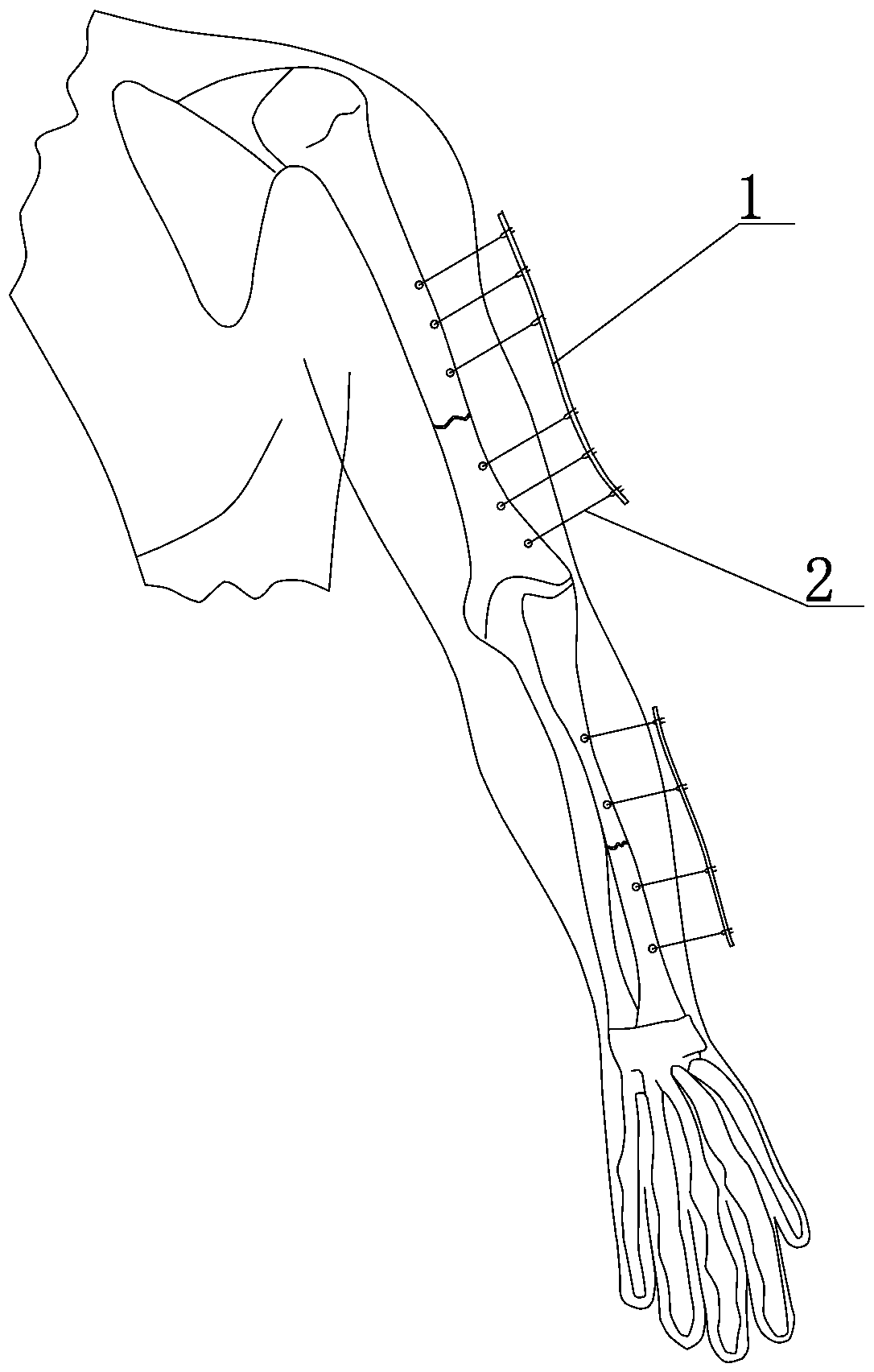

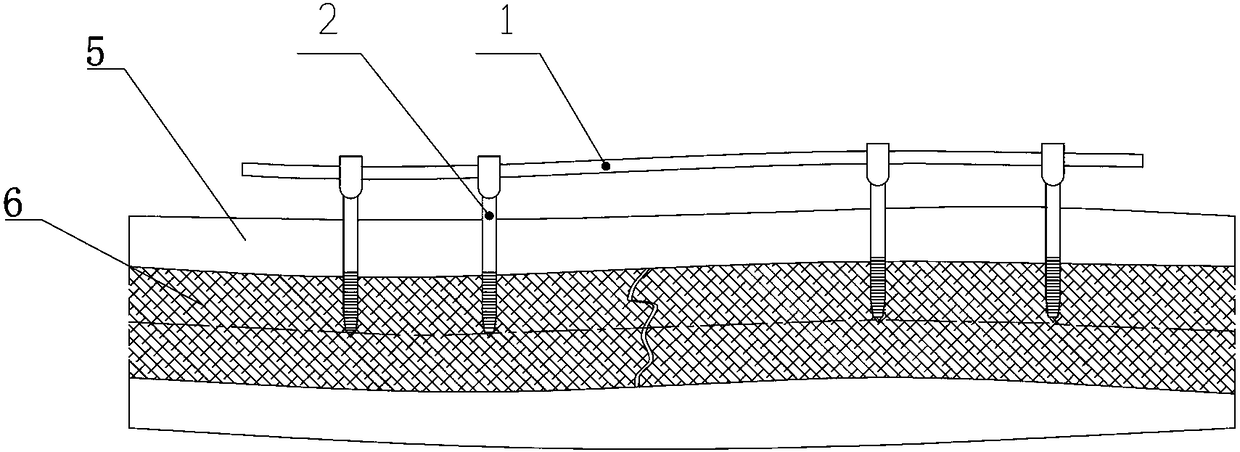

[0025] Embodiment 1: as figure 1 and figure 2 The shown fracture external fixator installation assembly includes an anatomical rod 1 and a plurality of Y-shaped radial fixation nails 2 . Among them, each Y-shaped radial fixation nail 2 is vertically fixed on the bone layer 6 on both sides of the fracture site, and the anatomical rod 1 is an arc-shaped rod consistent with the curvature of the fracture site, and the anatomical rod 1 is fixed on each Y-shaped radial fixation The end of nail 2 constitutes a fixed whole. Since the curvature of the anatomical rod 1 is consistent with the fracture site, the anatomical rod 1 and the fracture site can be kept in an approximately parallel state, so that the anatomical rod 1 can be used to connect and strengthen the two sides of the fracture to ensure a stable butt joint of the fracture site.

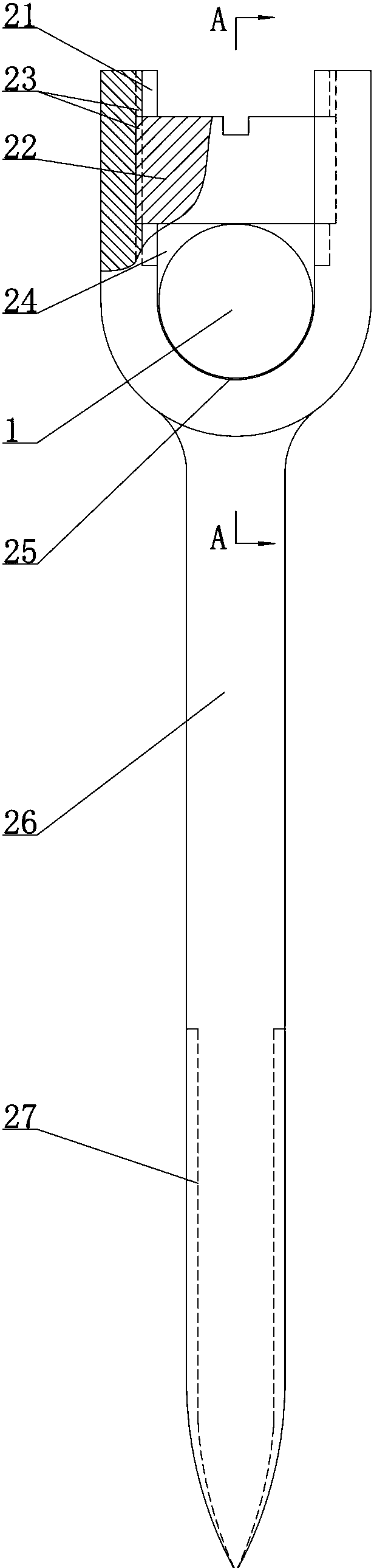

[0026] Such as image 3 As shown, the upper end of each Y-shaped radial fixing nail 2 is provided with a Y-shaped fork 21 , the middle part i...

Embodiment 2

[0036] Embodiment 2: On the basis of Embodiment 1, another positioning sleeve 4 is adopted, such as Figure 12 shown. The inner wall of the horizontal tube 41 of the positioning sleeve 4 is a cylindrical hole 47 , and an inner sleeve 44 is set in the cylindrical hole 47 , and a locking screw 46 is connected between the horizontal tube 41 and the inner sleeve 44 . The inner wall of the inner sleeve 44 is provided with an anti-rotation block 45 parallel to the axial direction. This is a positioning sleeve 4 with a composite structure, in which the inner sleeve 44 and the model positioning rod cannot rotate, which ensures the anti-rotation constraint relationship. The horizontal tube 41 can rotate along the inner sleeve 44, but it can be locked by the locking screw 46 to ensure that the horizontal tube 41 and the inner sleeve 44 do not rotate. This embodiment can realize the purpose of the rotation of the horizontal tube 41 and the inner sleeve 44 under special circumstances, i...

Embodiment 3

[0037] Embodiment 3: on the basis of embodiment 1, adopt such as Figure 13 As shown in the fixed sleeve, the inner wall of the horizontal tube 41 of the positioning sleeve 4 is a cylindrical hole 47, and the horizontal tube 41 is matched with the end of each model positioning rod. Horizontal tube 41 side walls are vertically provided with locking screw 46, utilize locking screw 46 to fix together horizontal tube 41 and each model positioning bar end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com