Single-rod four-nail fracture external fixation frame

An external fixator and single-rod technology, applied in the field of fracture positioning frame, to achieve the effect of reducing operation cost, volume and weight, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

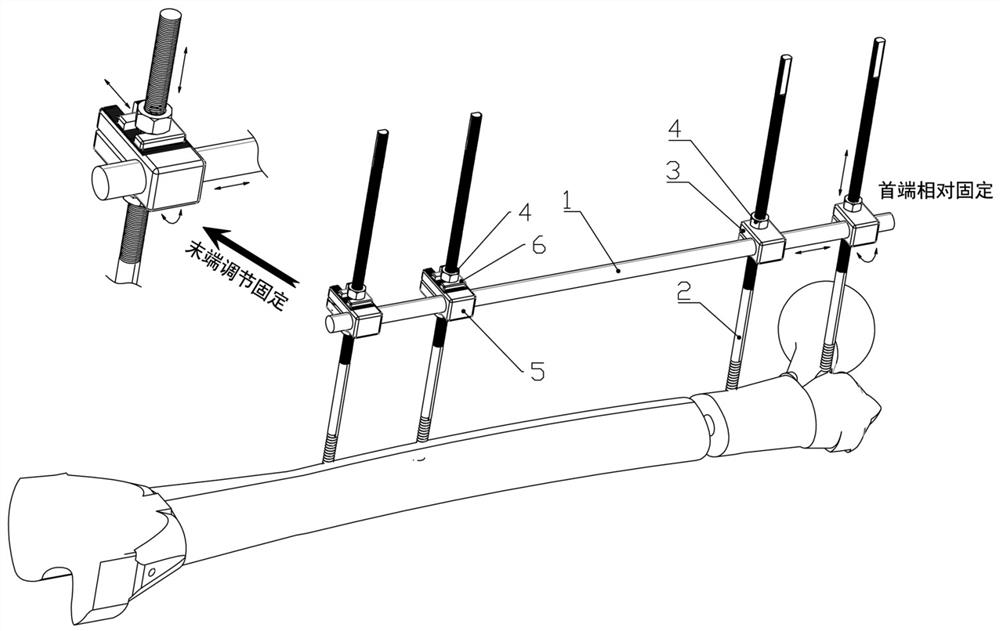

[0034] Embodiment 1: A single-rod four-nail external fixator with absolute adjustment of the head end relative to the adjustment end, such as figure 1 As shown, the fixing frame includes two head-end fixing parts 3 and two head-end fixing nails 2 , two end multi-dimensional fixing parts 5 and two end fixing nails 2 , and a straight connecting rod 1 .

[0035] The outer sides of the two fixing nails at the head end respectively fix the head end of the connecting rod through the first end fixing part 3, and the outer sides of each fixing nail at the end respectively fix the end of the connecting rod through the end multi-dimensional fixing part 5.

[0036] As can be seen from the figure, the lower end of the rod body of each fixing nail 2 is a self-tapping thread section 21 for screwing into the bone, and the upper section has a threaded section 22 for installing a lock nut.

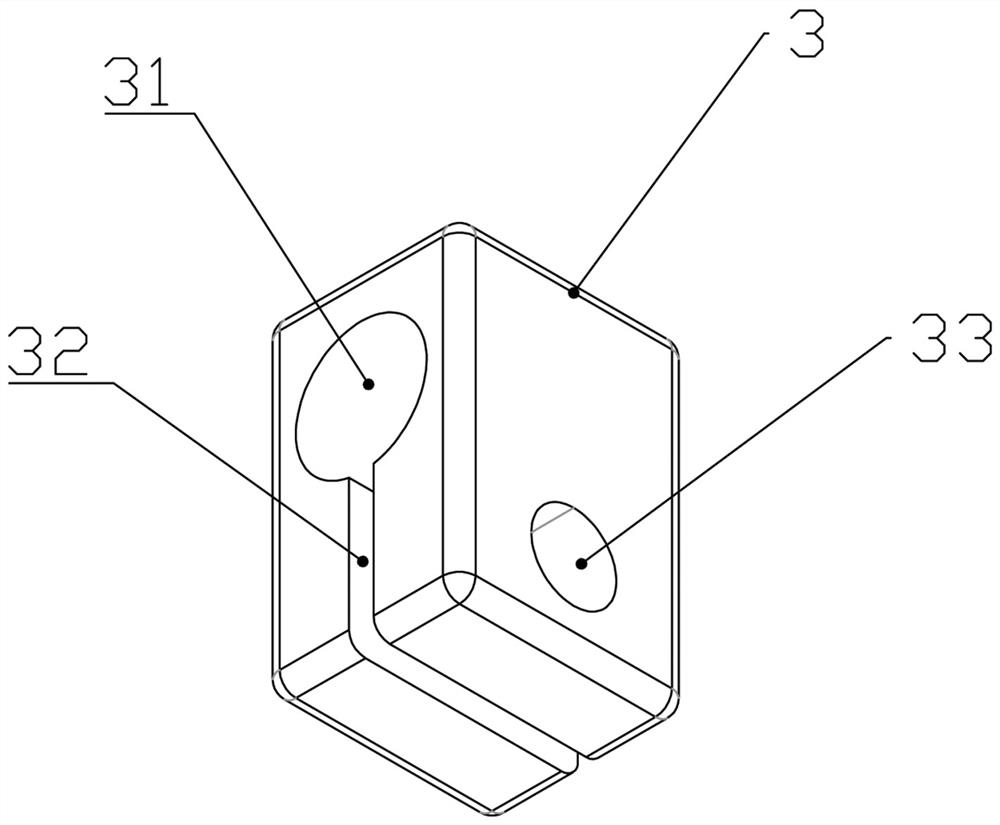

[0037] Such as figure 2 There is a connecting rod through hole 31 on one side of the main body of the...

Embodiment 2

[0049] Embodiment 2: A single-rod four-nail external fixator for fractures with the head end fixed and the end adjusted. The structure of the external fixator is as follows: Figure 8 with Figure 9 As shown, it includes two head-end fixing structures and two head-end fixing nails 2 , two end multi-dimensional fixing parts 5 and two fixing nails 2 .

[0050] It can be seen from the figure that the head-end fixing structure means that at least two through-holes are set at the head-end of the connecting rod. Secured by lock nut. The lower ends of the rod bodies of the four fixing nails 2 are self-tapping thread sections 21 for screwing into the bone, and the upper section has a threaded section 22 .

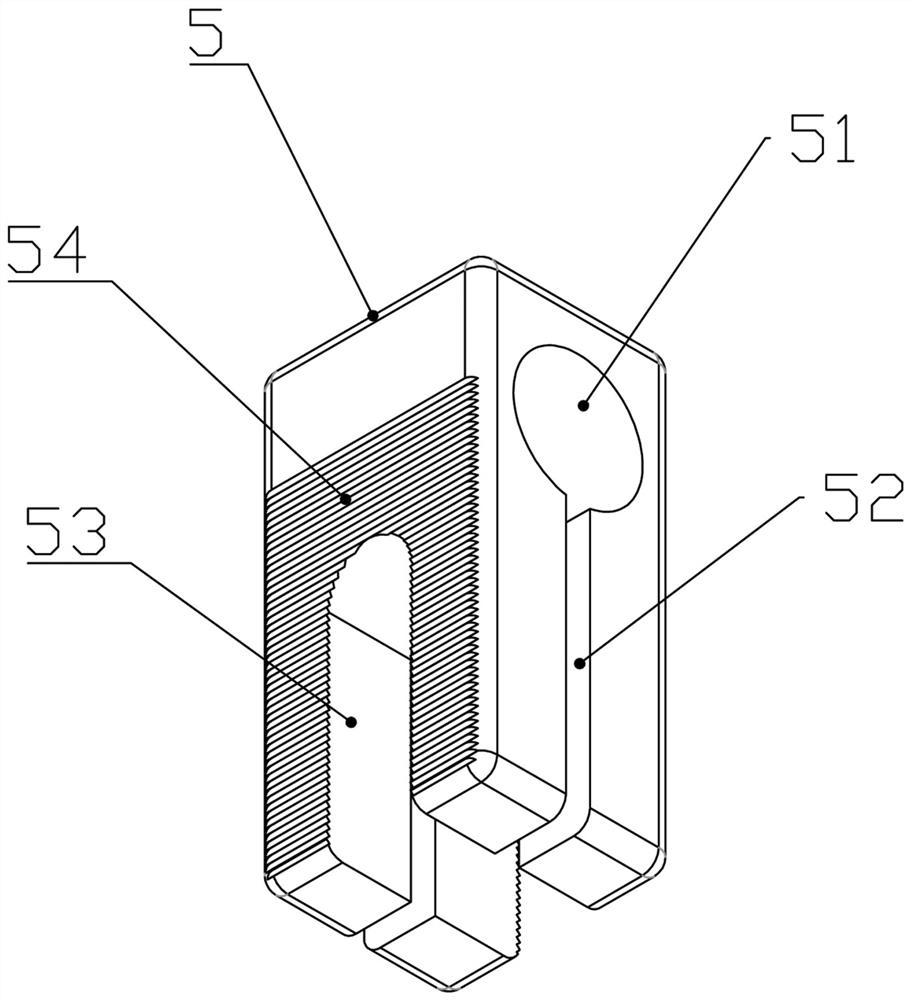

[0051] The outer sides of each fixing nail at the end respectively fix the end of the connecting rod through the multi-dimensional fixing member 5 at the end. Specifically, one side of the main body of the terminal multi-dimensional fixing member 5 has a connecting rod through h...

Embodiment 3

[0053] Embodiment 3: On the basis of Embodiment 1, the connecting rod in this embodiment has a curved arc 9 in the middle of the straight connecting rod. Such as Figure 10 As shown, nails A and B are still parallel, and nails C and D are parallel, but nails A and B on both sides are inclined outward at the same time, and nails C and D are inclined outward at the same time. At this time, only straight connecting rods are used. The four nails A, B, C, and D cannot be fixed as one. However, the angle α between the extension line of the connecting rod perforation of nail A and nail B and the extension line of nail C and nail D can be easily determined, so that only one angle bending tool is needed to bend the straight connecting rod to The arc of the included angle α can realize the fixing of the four nails A, B, C, and D as one. Furthermore, the same structural performance as that of Embodiment 1 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com